Piezoelectric electret film and producing method thereof

A piezoelectric electret and a manufacturing method technology, applied in chemical instruments and methods, lamination, lamination devices, etc., can solve problems such as the inability to achieve fine control of the microstructure of thin films

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The piezoelectric electret thin film of the present invention and its manufacturing method will be further described in detail below mainly in conjunction with the accompanying drawings and embodiments.

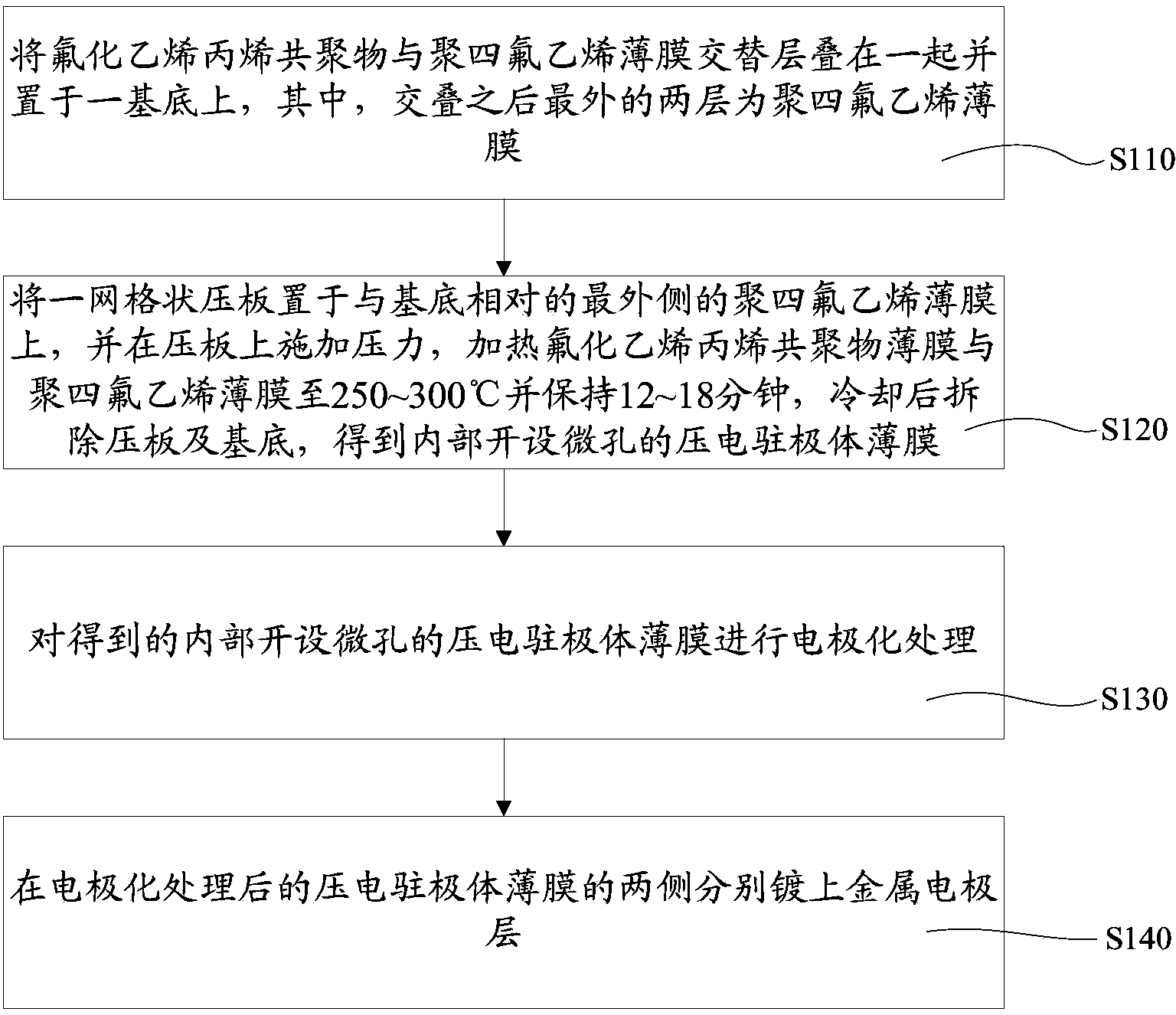

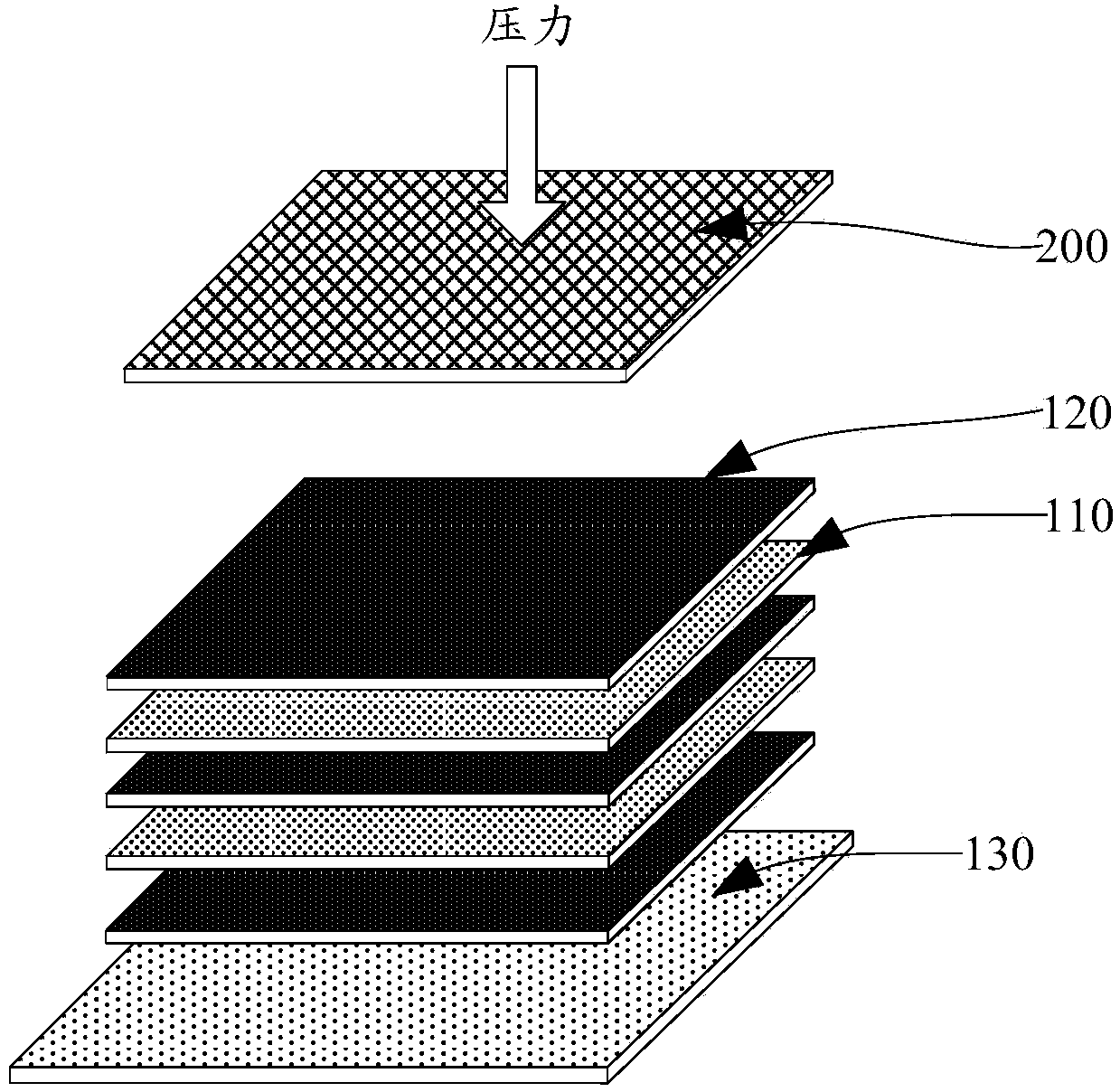

[0027] Such as figure 1 with figure 2 Shown, the fabrication method of the piezoelectric electret thin film of one embodiment, comprises the following steps:

[0028] In step S110, fluorinated ethylene propylene copolymer (FEP) films 110 and polytetrafluoroethylene (PTFE) films 120 are alternately stacked together and placed on a substrate 130, wherein the outermost two layers after overlapping are polytetrafluoroethylene (PTFE) films. Vinyl fluoride film 120.

[0029] In this embodiment, the thickness of the fluorinated ethylene propylene copolymer film 110 is 7-15 μm, and the thickness of the polytetrafluoroethylene film 120 is 2-7 μm.

[0030] The quantity of the FEP film 110 can be one layer, or multiple layers, such as two layers, three layers, four layers and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com