Positioning device for fast cutting of slats on woodworking sawing machines

A rapid cutting and positioning device technology, applied in the direction of sawing components, sawing equipment, wood processing equipment, etc., can solve the problems of easy and incoherent operation, poor cutting quality, and increased workload of operators, so as to improve quality and improve Competitiveness, the effect of accurate processing size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

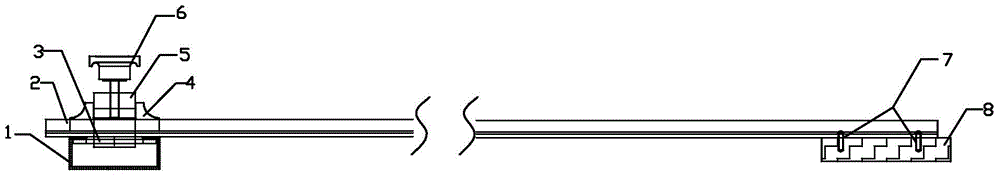

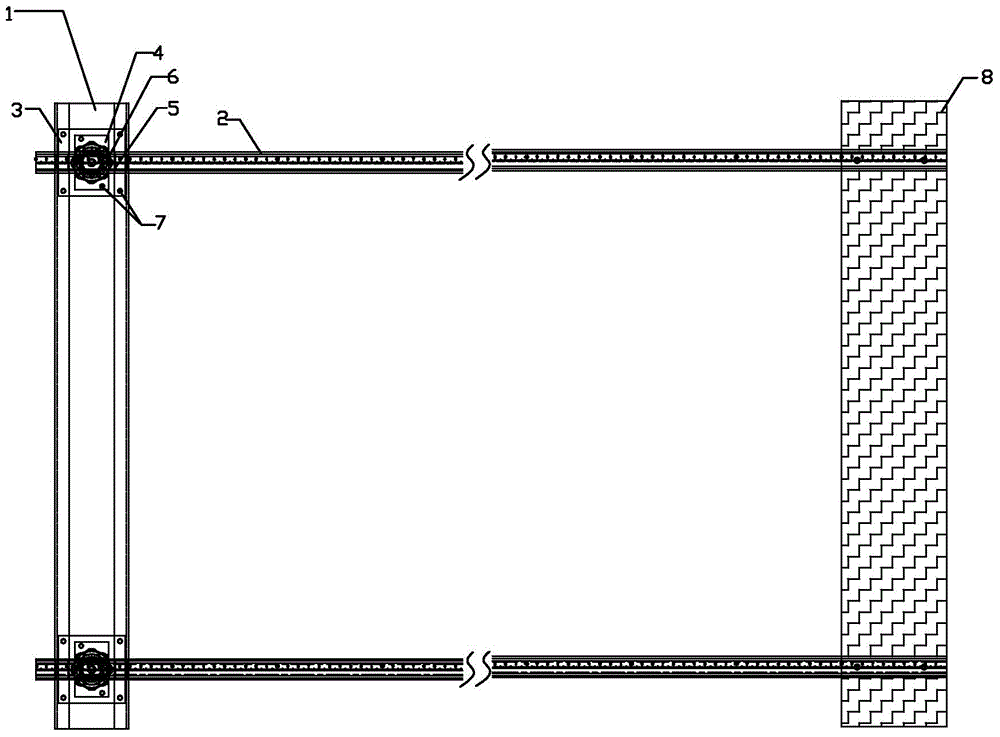

[0019] Reference Figure 1 to Figure 6 , The positioning device of the present invention for woodworking sawing machine to quickly cut slats includes a fixed groove plate 1, two ends of the fixed groove plate 1 are respectively provided with connecting plates 3, the connecting plate 3 and the fixed groove plate 1 Screws 7 are used to fix and connect; the connecting plate 3 is provided with a movable positioning ruler 2, and the positioning ruler 2 is provided with a connecting seat 4 for pressing it on the connecting plate 3. 4 is provided with a second connecting seat 5, the second connecting seat 5 has a groove-shaped end surface with a downward opening, and the two side end surfaces of the connecting seat 4 are clamped by the groove-shaped end surface. The bottom of the profile end surface is provided with an outer edge connected to the connecting plate 3. The outer edge of the bottom of the connecting seat 2 5 is fixedly connected with the connecting plate 3 by screws 7; th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com