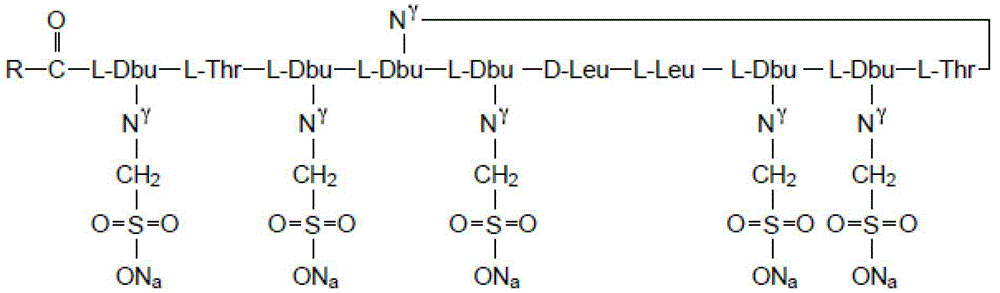

A kind of polymyxin e sodium methanesulfonate freeze-dried preparation and preparation method thereof

A technology of sodium methanesulfonate and polymyxin, which is applied in the field of medicine, can solve the problems of large particle size, collapsed appearance of polymyxin E sodium methanesulfonate freeze-dried preparation, and many insoluble particles, and achieves uniform crystal form. , The appearance is full, the effect of easy rehydration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

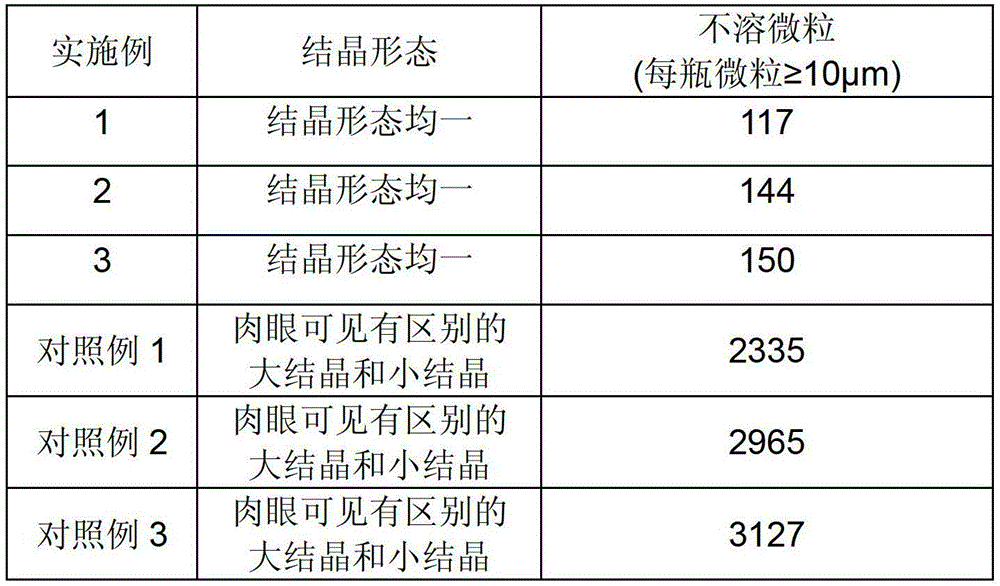

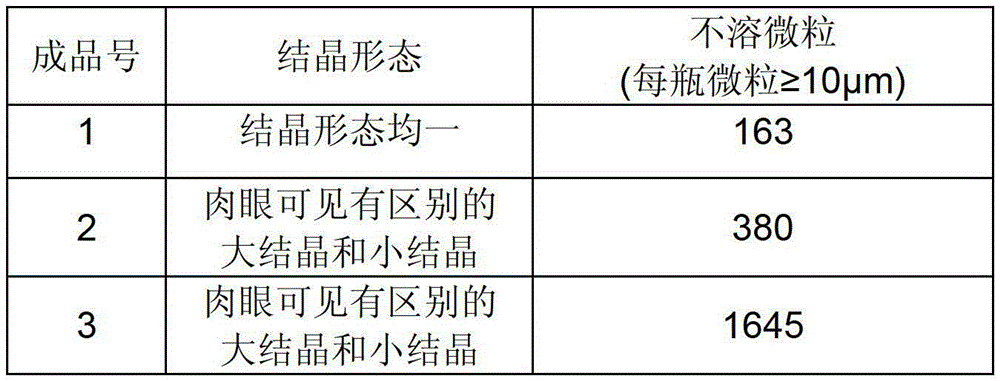

Examples

Embodiment 1

[0037] Sodium polymyxin E methanesulfonate 0.077g

[0038] Add water for injection to make 2ml solution

[0039] Add the prescribed amount of polymyxin E sodium methanesulfonate into the water for injection, stir and dissolve, pass through a 0.22 μm microporous filter membrane for sterile filtration, and fill the filtrate into 10ml vials with 2ml each aseptically, and half-tighten the stopper to the freeze dryer. Control the temperature of the front box of the freeze dryer at -30°C to -35°C, pre-freeze the product to this temperature and maintain it for 2 hours, and at the same time the temperature of the cold trap drops to -60°C; adjust the temperature of the partition to -15°C, when the product rises to this temperature Maintain the temperature for 2 hours; adjust the temperature of the partition to -30°C ~ -35°C again, and maintain it for 1 hour after the product drops to this temperature; turn on the vacuum pump, and then adjust the temperature of the partition to 0°C, wh...

Embodiment 2

[0041] Sodium polymyxin E methanesulfonate 0.155g

[0042] Add water for injection to make 2ml solution

[0043] Add the prescribed amount of polymyxin E sodium methanesulfonate into the water for injection, stir and dissolve, pass through a 0.22 μm microporous filter membrane for sterile filtration, and fill the filtrate into 10ml vials with 2ml each aseptically, and half-tighten the stopper to the freeze dryer. Control the temperature of the front box of the freeze dryer at -40°C to -45°C, pre-freeze the product to this temperature and maintain it for 3 hours, and at the same time the temperature of the cold trap drops to -60°C; adjust the temperature of the partition to -15°C, when the product rises to this temperature Maintain the temperature for 3 hours; adjust the temperature of the partition to -40°C ~ -45°C again, and maintain it for 1 hour after the product drops to this temperature; turn on the vacuum pump, and then adjust the temperature of the partition to 0°C, wh...

Embodiment 3

[0045] Sodium polymyxin E methanesulfonate 0.310g

[0046] Add water for injection to make 2ml solution

[0047] Add the prescribed amount of polymyxin E sodium methanesulfonate into the water for injection, stir and dissolve, pass through a 0.22 μm microporous filter membrane for sterilizing filtration, and the filtrate is aseptically filled in 10ml vials with 2ml each, and half-tightened to the freeze dryer. Control the temperature of the front box of the freeze dryer at -40°C to -45°C, pre-freeze the product to this temperature and maintain it for 3 hours, and at the same time the temperature of the cold trap drops to -60°C; adjust the temperature of the partition to -15°C, when the product rises to this temperature Maintain the temperature for 3 hours; adjust the temperature of the partition to -40°C ~ -45°C again, and maintain it for 2 hours after the product drops to this temperature; turn on the vacuum pump, and then adjust the temperature of the partition to 0°C, when...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com