Bivalve processing device

A processing device and technology of bivalve shellfish, applied in the field of bivalve shellfish processing devices, can solve problems such as deterioration of precision, drop in productivity, inability to reliably open shells, etc., and achieve excellent results in high performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

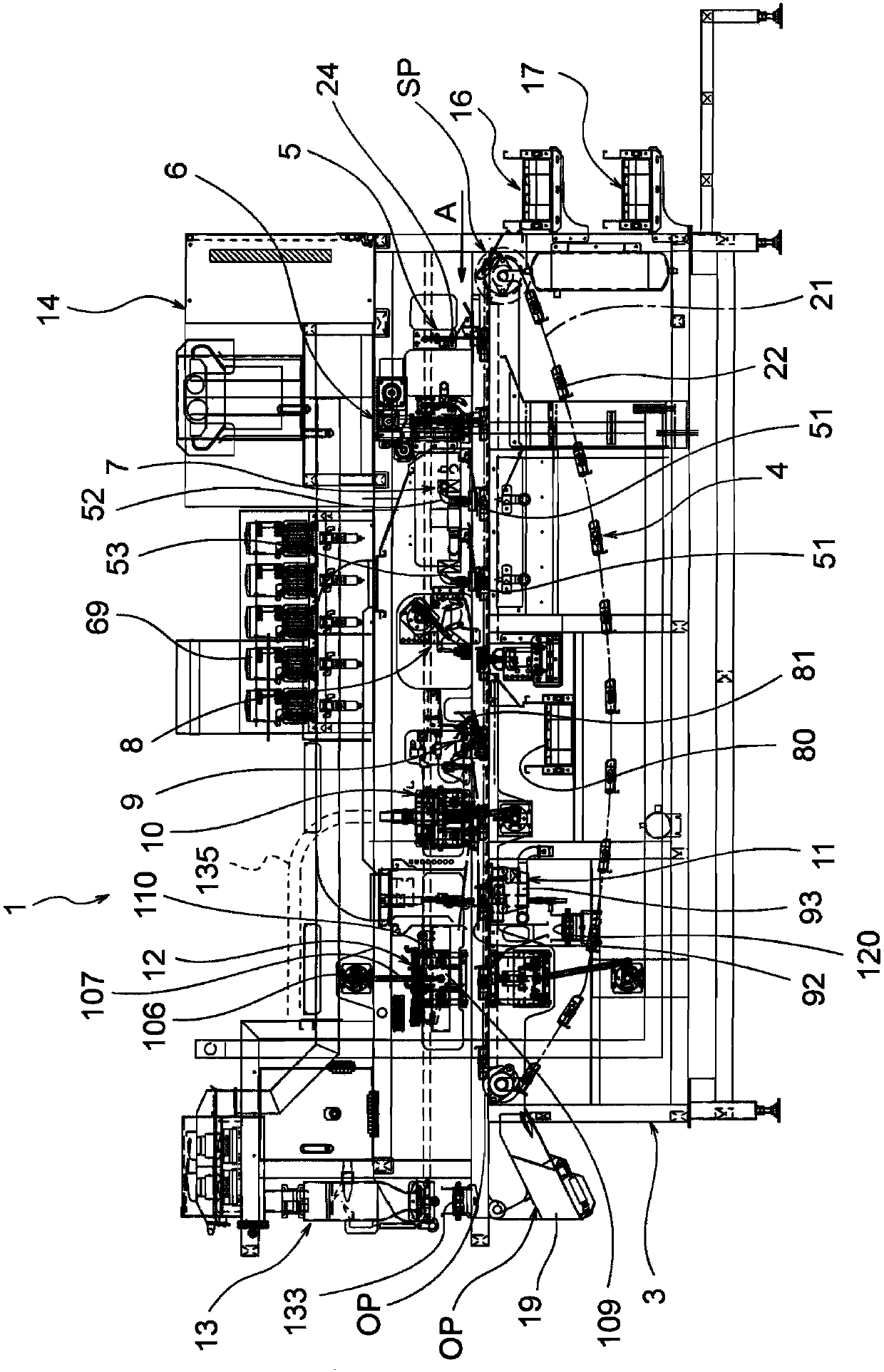

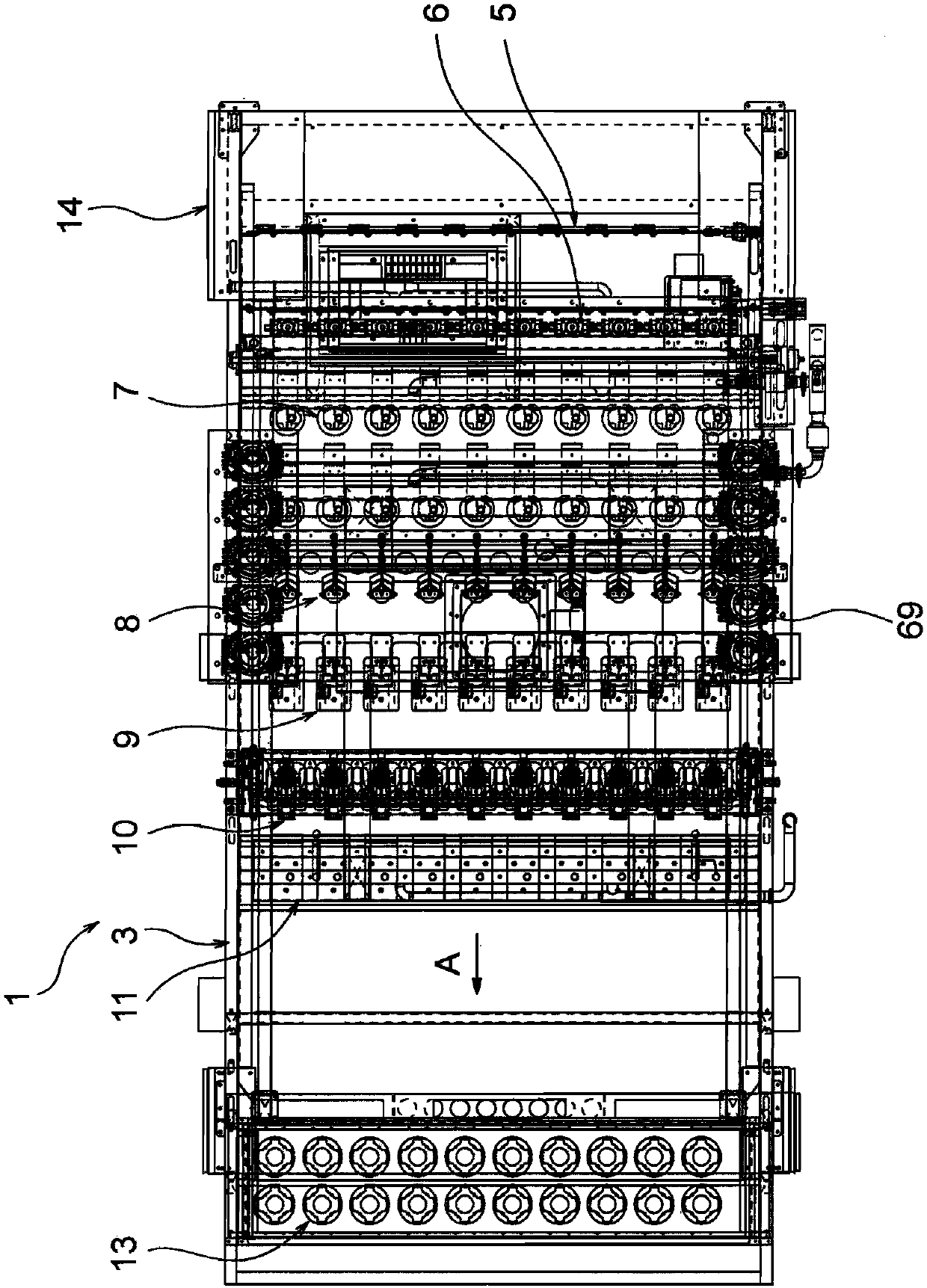

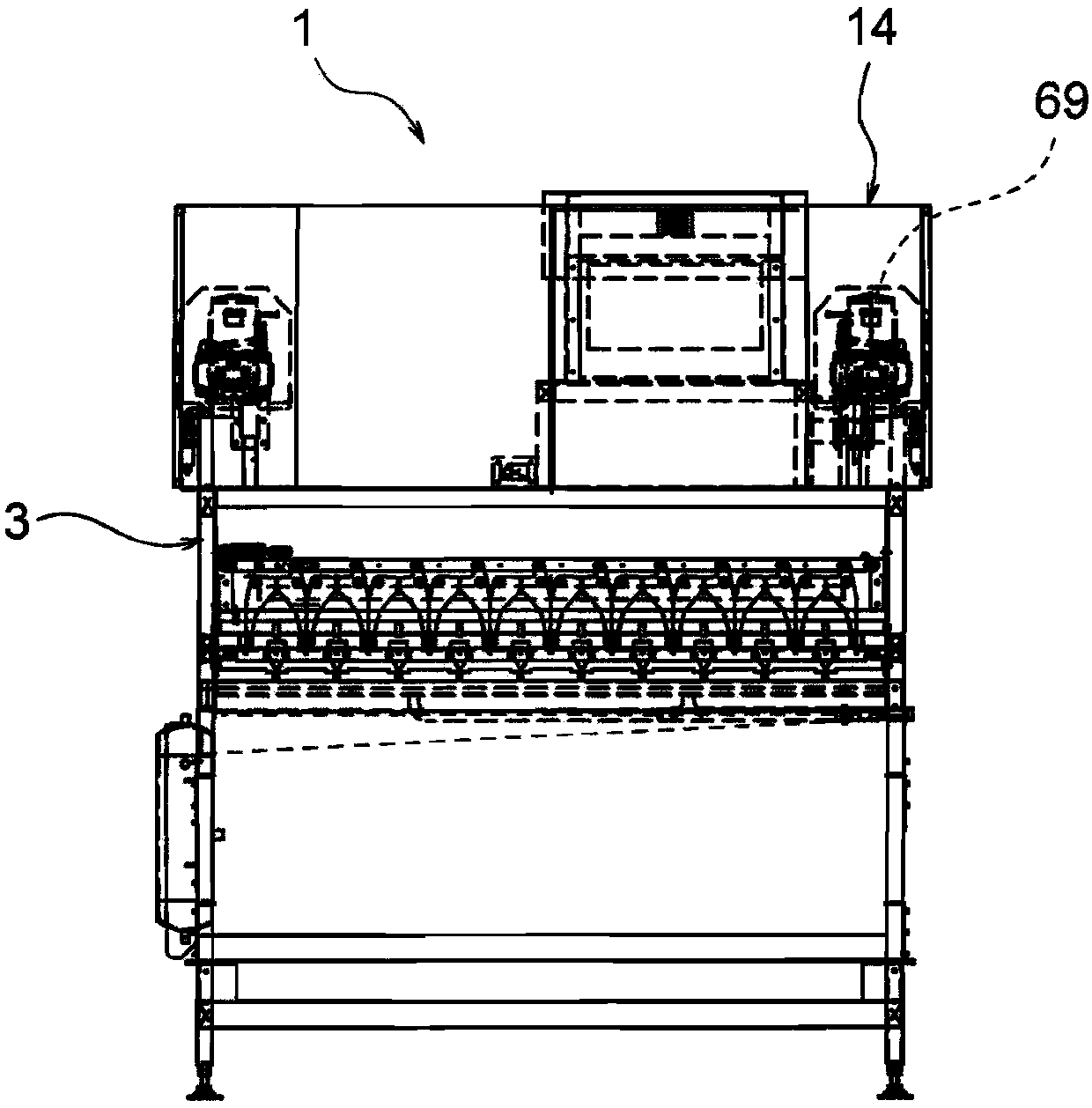

[0045] Hereinafter, the present invention will be described based on the embodiments shown in the drawings.

[0046] The bivalve shell processing device 1 of the present embodiment is an example in which unprocessed shellfish made of bivalve shells are natural raw scallops 2, and an unillustrated shell made of dried shellfish and small sticks as the edible part for raw food is used. The adductor muscle is effectively removed from the scallop 2 in a state where the adductor muscle is integrated.

[0047] Such as Figure 1 to Figure 3 As shown, the bivalve shellfish processing device 1 of this embodiment is provided with a conveying mechanism 4, a raw shellfish positioning mechanism 5, a foreign matter removing mechanism 6, a first heating mechanism 7 as a heating mechanism, a forced opening mechanism 8, The shell separating mechanism 9, the non-edible part separating mechanism 10, the second heating mechanism 11, the edible part taking-out mechanism 12, the collecting mechanis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com