Method for treating inner surface of chlorine trifluoride supply path in device using chlorine trifluoride

A chlorine trifluoride, treatment method technology, applied in the direction of circuit, gaseous chemical plating, coating, etc., can solve the problem of ClF3 concentration reduction, etc., and achieve the effect of reducing the inhibitory concentration, reducing the inhibitory concentration, and significant negative effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

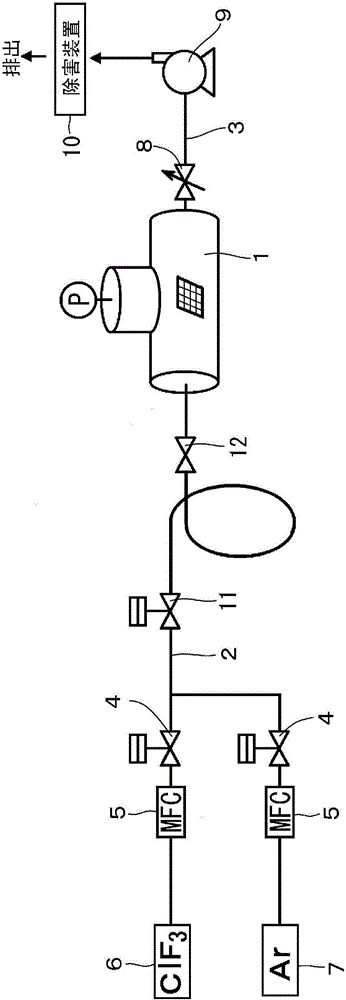

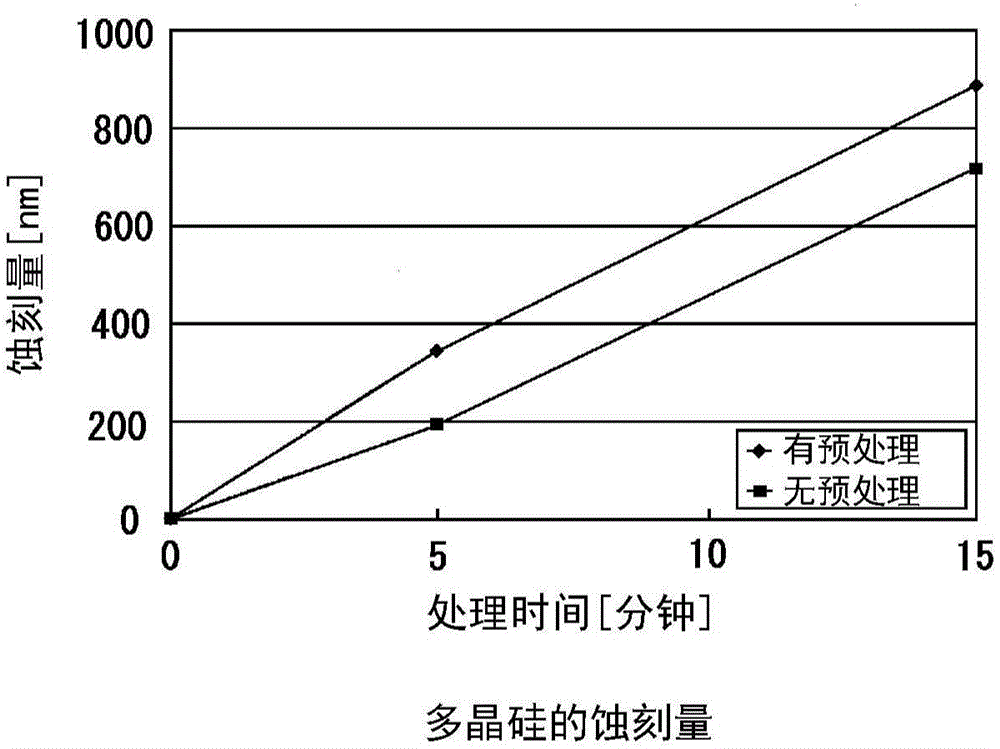

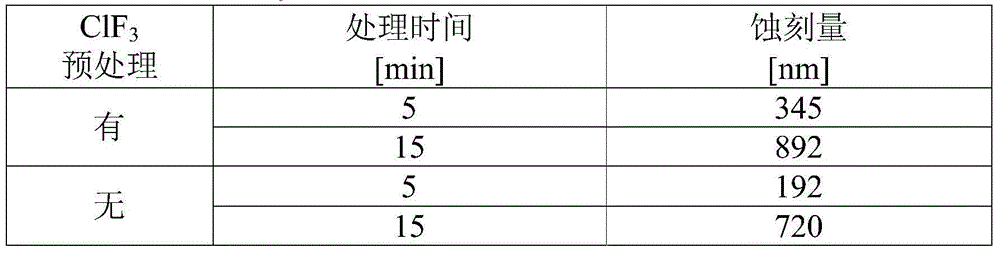

[0027] For comparison with and without pre-implementation of ClF 3 The effect of gas exposure treatment on etching treatment, by figure 1 In the device shown in , as the piping constituting the gas supply path (2), ClF was performed in advance under the conditions shown below. 3 The pipes exposed to gas and the pipes not exposed were etched under the conditions shown below with respect to samples formed by forming a polysilicon film placed in the processing chamber (1). In addition, as the reduction of ClF 3 The gas supply path (2) between the pneumatic valve (11) and the manual valve (12), which is the main part of the gas concentration, is formed with a pipe diameter of 1 / 4" and a pipe length of 4m (pipe inner wall surface area: 54636mm 2 ).

[0028] CIF 3 The pre-exposure treatment conditions are shown below.

[0029] CIF 3 Gas concentration: 100%;

[0030] Temperature: room temperature (20°C).

[0031] In addition, ClF 3 The pre-exposure was achieved by adding 100...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com