Production method for frozen cooked pasta

一种制造方法、面食的技术,应用在食品冷冻、食品制备、食物科学等方向,能够解决缺少口感等问题,达到防止外观或口感的降低、良好品质、维持品质的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

manufacture example 1~8

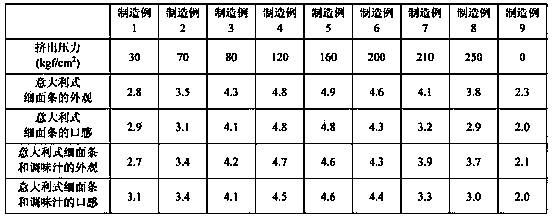

[0041] 26 parts by mass of water were mixed with 100 parts by mass of durum wheat semolina (レオーネG: manufactured by Nissin Milling Co., Ltd.), and kneaded to form a dough. Using a pasta maker at 30, 70, 80, 120, 160, 200, 210 and 250 kgf / cm under a reduced pressure of -600 mmHg 2 The dough was extruded under the pressure condition of 8 kinds of raw spaghetti (thickness 1.8mm).

[0042] The obtained raw spaghetti was boiled in hot water for 5 minutes, and the water was cooled to manufacture boiled spaghetti.

[0043] 30 parts by mass of soybean oil (melting point -7° C.) and 0.2 parts by mass of a thickening polysaccharide were mixed, and 5 parts by mass of water were added to the obtained mixed liquid, followed by mixing to prepare a coating liquid. Next, the above-mentioned coating solution in an amount of 5% of the mass of the boiled spaghetti was sprayed onto the whole spaghetti noodles by spraying, so that the entire amount of the coating solution was attached to the boile...

manufacture example 9

[0046] By stretching the above dough with a rolling noodle machine (pressure 0 kgf / cm 2 ), cut out to obtain raw spaghetti (thick 1.8mm). The obtained raw spaghetti was boiled in the same procedure as in Production Example 1, coated with the coating liquid, and frozen to produce frozen cooked spaghetti (with or without sauce) in Production Example 9.

manufacture example 10~17

[0054] Except for adding water in the amount shown in Table 3 to 100 parts by mass of Duran wheat semolina (レオーネ G: manufactured by Nissin Semolina), follow the same procedure as Production Example 5 (pressure for extrusion noodle making: 160 kgf / cm 2 ), the frozen cooked spaghetti of Production Examples 10-17 (respectively without sauce and with sauce) were produced. Using the frozen cooked spaghetti of Production Examples 10 to 17, spaghetti after thawing in the same procedure as Test Example 1, or the appearance and food texture of spaghetti and sauce were evaluated. The results are shown in Table 3.

[0055] 【table 3】

[0056]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com