Battery testing station and testing method thereof

A technology of battery testing and charging and discharging testing, applied in the direction of measuring electricity, measuring devices, measuring electrical variables, etc., can solve the problems that cannot meet the battery charging and discharging tests, and achieve the effect of improving production testing efficiency and facilitating quality monitoring

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

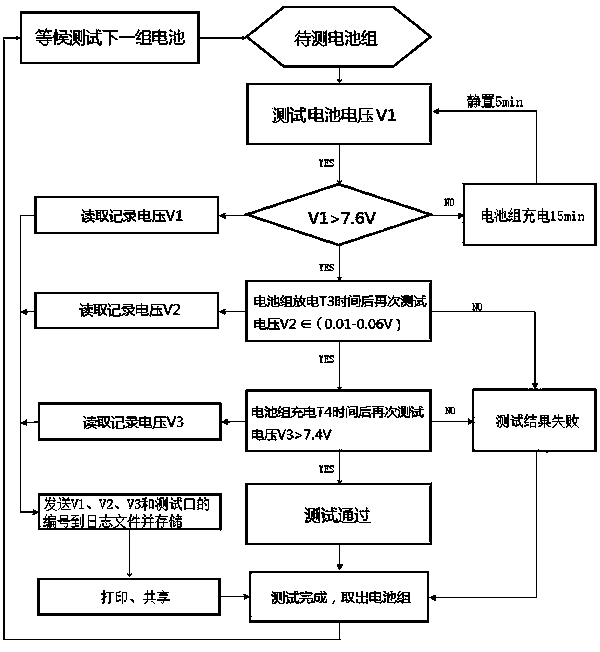

[0031] Such as figure 1 As shown, the present invention discloses a battery testing station, comprising:

[0032] 30 groups of battery charge and discharge test ports, each group of battery charge and discharge test ports includes a battery voltage test port, a battery charging unit and a battery discharge unit, the discharge unit adopts a PTC resistor; the battery charge and discharge test port is fixed with a battery set of test fixtures;

[0033] switch group, the switch group includes 30 groups of switches, each group of switches includes a battery voltage test port connected to a group of battery charge and discharge test ports, the first switch K1 of the battery discharge unit and the battery charge unit, the second The second switch K2 and the third switch K3; wherein the first switch K1 is a double-pole switch, and the two contacts are respectively connected to the two poles of the voltage test port;

[0034] The controller is connected to the switch group through th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com