Bend two-way self-limiting corrugated expansion joint

A technology of bellows and compensators, which is applied in the direction of expansion compensation devices for pipelines, pipes/pipe joints/fittings, pipe components, etc. Short service life, large welding area, etc., to achieve the effect of reducing distortion, reducing welding area, and reducing welding stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below according to the accompanying drawings and in conjunction with the embodiments.

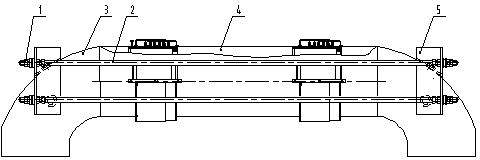

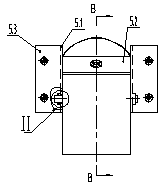

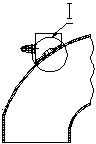

[0017] The elbow two-way self-limiting bellows compensator shown in the attached figure includes an expansion joint 4, an elbow 3, a support assembly 5, a nut 1, and a tie rod 2; the expansion joint 4 is connected between the elbows 3 at both ends to form a compensation Structure; the support assembly 5 is a symmetrical structure, including the middle elbow connecting plate 5.2, the side plates 5.1 fixedly connected on both sides of the elbow connecting plate 5.2 and the tie rod connecting plate 5.3 longitudinally fixedly connected to the side plate 5.1; the support Components 5 ride on the back of the elbow 3 at both ends; the support components 5 at both ends are connected by a tie rod 2 and a nut 1; the back of the elbow 3 is provided with a pin I7, and the side is provided with a pin II8; the support component 5 is an elbow The conn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com