Adjustable hinge

An adjustable, hinged technology, applied in folding boards, door/window accessories, construction, etc., can solve the problems of low production efficiency of printing process, inconsistent upper and lower gaps, expansion openings of shaft sleeves, etc. The gap is uniform and the effect of avoiding deformation opening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

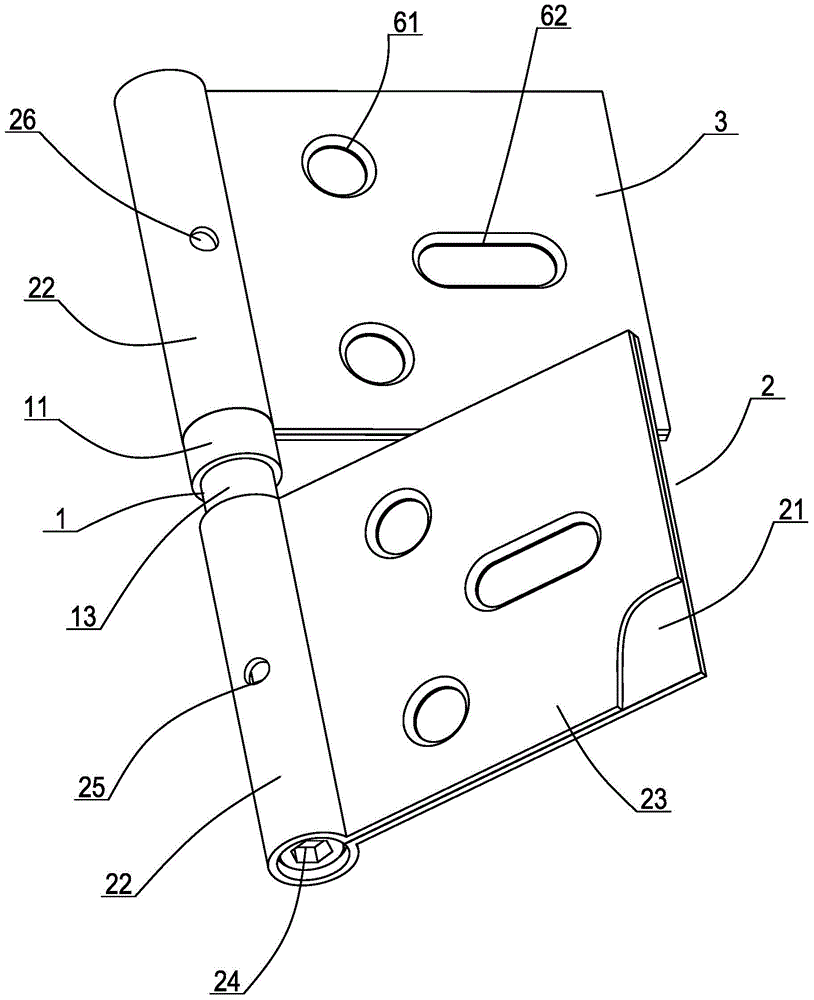

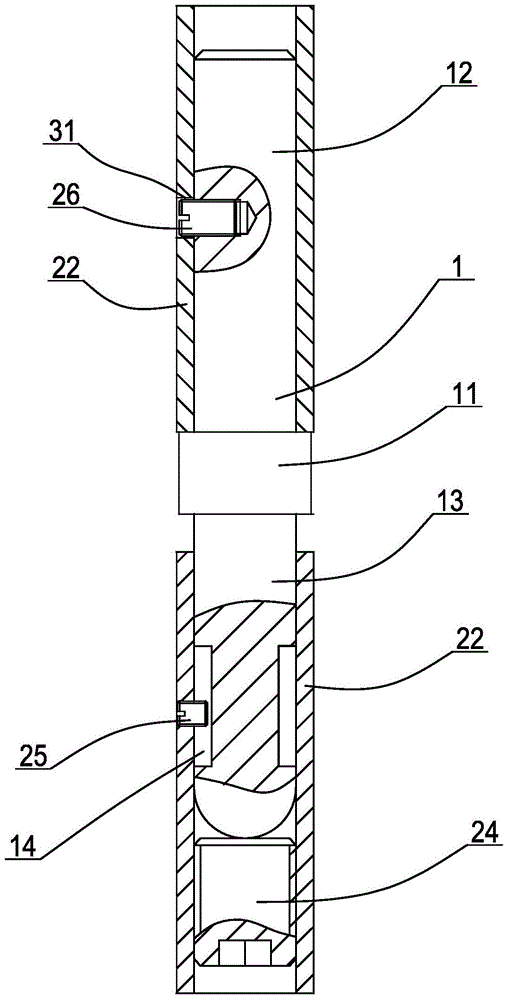

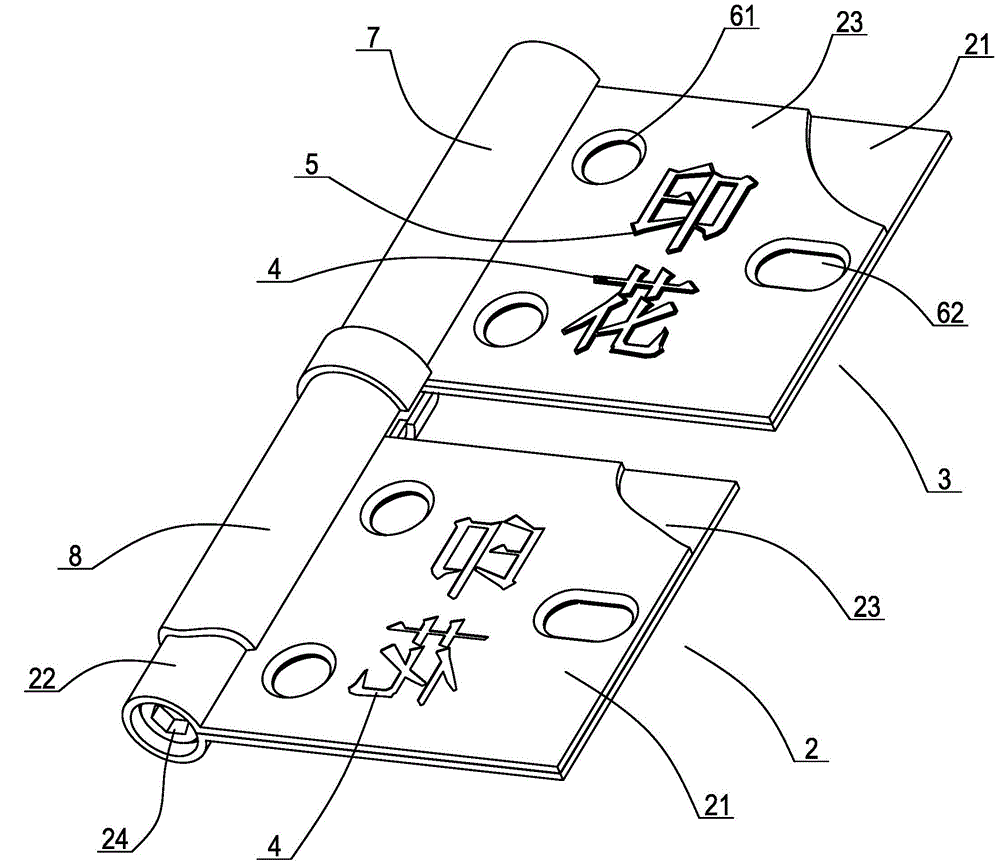

[0039] Such as figure 1 As shown, an adjustable hinge includes a left leaf 2, a right leaf 3 and a shaft rod 1, and the left and right leafs include a substrate 21 provided with a fixing hole for installation, and one side of the substrate faces outward. The sleeve 22 formed by curling is extended and bent toward the upper surface side of the substrate. Such as figure 2 As shown, the middle part of the shaft is provided with an outwardly protruding collar 11, thereby separating the shaft into an upper section 12 and a lower section 13. The bushing of the right leaf is rotatably connected to the upper section on the upper side of the collar on the shaft, while the left leaf The shaft sleeve of the sheet is then rotatably connected to the lower section of the lower side of the collar on the shaft, and the shaft sleeve of the left sheet is prov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com