Horizontal connection node of prefabricated shear wall

A horizontal connection, prefabricated shear force technology, applied in the direction of walls, building components, buildings, etc., can solve the problem of no special research on the connection form, and achieve the effects of low cost, improved seismic performance, and convenient construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described below in conjunction with the accompanying drawings.

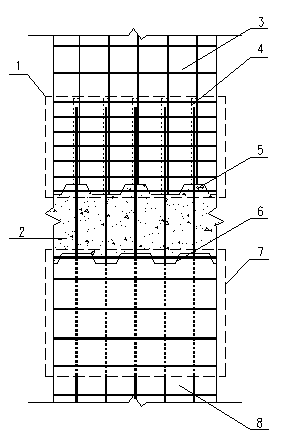

[0033] Such as Figure 1-3 As shown, the novel prefabricated shear wall horizontal connection node of the present invention includes an upper wallboard 3, a grouting area 2 and a lower wallboard 8, and the upper wallboard 3 and the lower wallboard 8 are connected through the grouting area 2; The lower end of the upper wallboard 3 is provided with a slurry anchor area 1 of a predetermined height, and several reserved holes 4 are evenly arranged in the slurry anchor area 1; the reserved holes 4 are provided with grouting ports and exhaust ports, so The grouting port described above is set at the lower end of the reserved hole 4, and the exhaust port is set at the upper end of the reserved hole 4; the slurry anchor area 1 is provided with a plurality of upper wallboard grooves near the end of the grouting area 2 5, the notch 5 of the upper wallboard communicates with the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com