A self-resetting friction damper

A friction damper and self-resetting technology, which is applied to building components, shockproof, etc., can solve problems such as large shear deformation, serious damage, and difficult repairs, and achieve strong self-resetting ability, strong self-resetting ability, and improved production efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

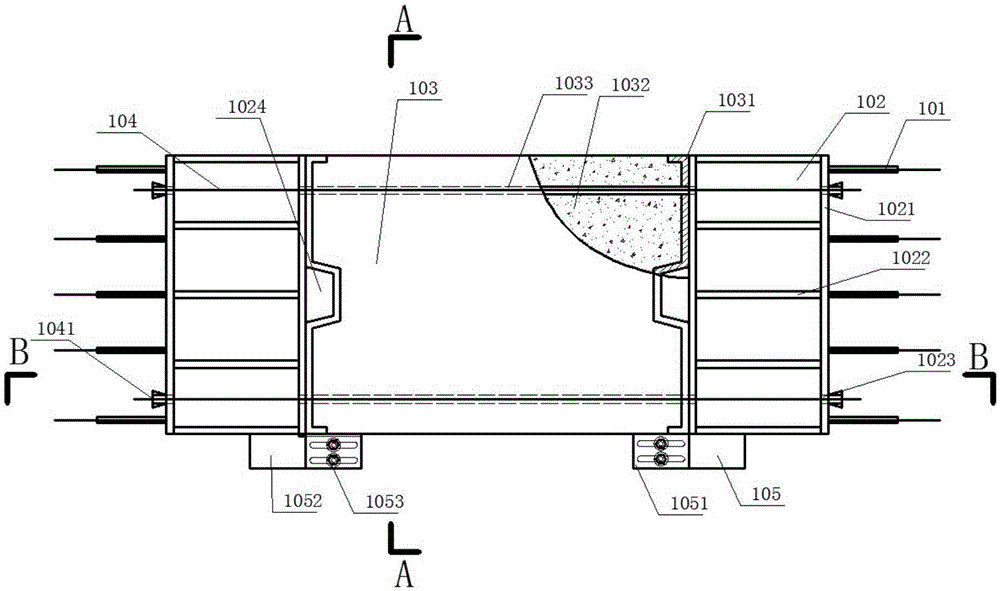

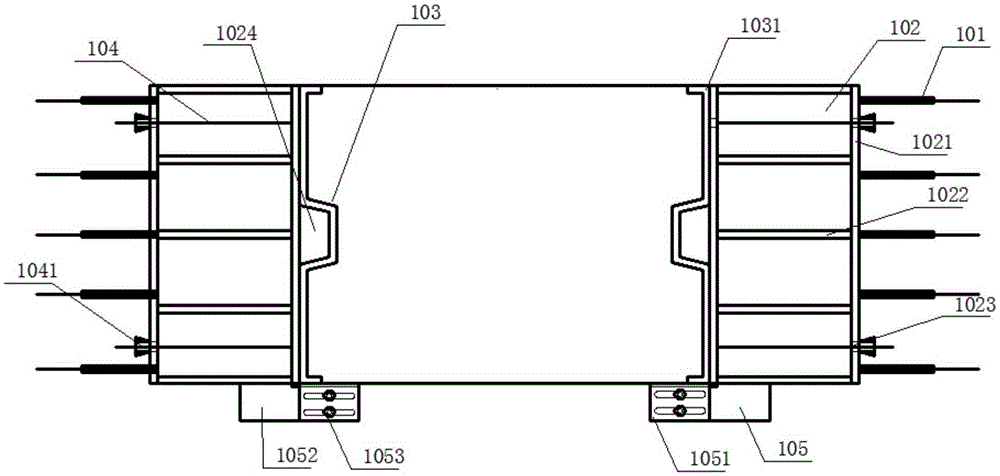

[0034] Such as figure 1 The shown self-resetting friction damper of the present invention includes: an anchoring steel bar 101, a section steel connection section 102, a steel plate concrete connection section 103, a prestressed cable 104 and a friction energy dissipation plate 105.

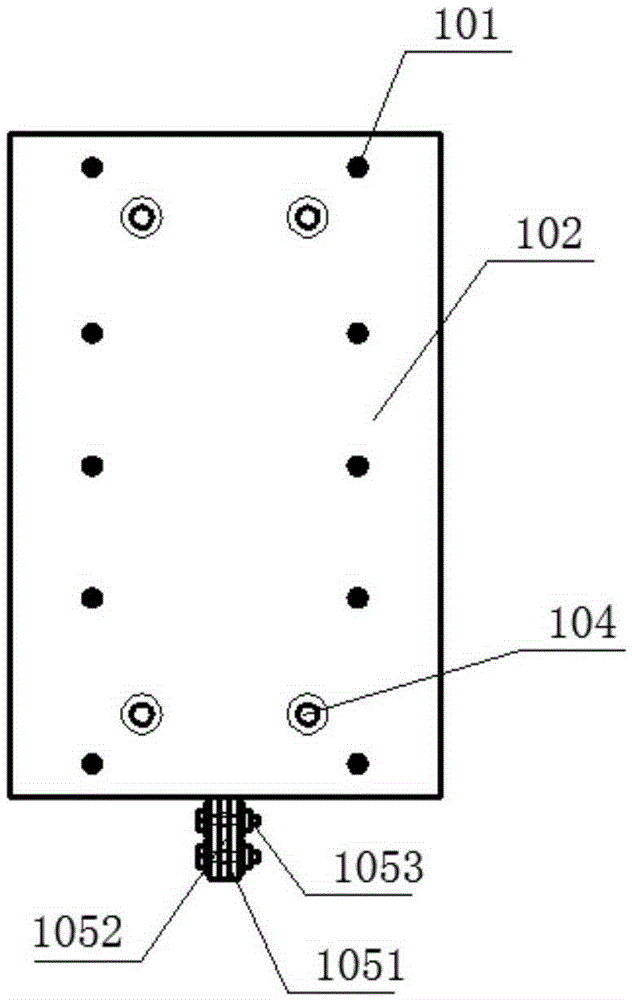

[0035] Anchor steel bars 101 are welded on the outside of section steel connecting section 102 and poured in the reinforced concrete main structure, such as figure 2 shown. According to needs, the anchoring steel bars 101 can be arranged in 4-6 rows, with 2-3 in each row.

[0036] The section steel connecting section 102 is welded by multiple parts, including: welded I-shaped steel plate 1021, stiffener 1022; at the same time, it is necessary to reserve a hole 1023 for the prestressed cable 104 on the flange of the welded I-shaped steel plate 1021; The shear connector 1024 is a small piece of steel plate welded on the section steel connection section 102, and is used to bear the shear force be...

Embodiment 2

[0042] Figure 9As another construction form of the invention, the prestressed cable 104 only passes through the left section steel connection section 102 , and the right side is anchored on the outside of the steel plate concrete connection section 103 . The steel plate concrete connecting section 103 and the steel connecting section 102 on the right are only connected by the shear connecting piece 1024 and the frictional energy dissipation plate 105 . Under an earthquake, the left shaped steel connecting section 102 bears bending moment and shearing force, and the right shaped steel connecting section 102 only bears shearing force.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com