Ice condensation resistant ultra-thin wearing course pavement and preparation method thereof

An anti-condensation ice and wear layer technology, which is applied to the condensable pavement, roads, roads and other directions paved on site, can solve the problems of imperfect traffic emergency system, serious environmental pollution of snow melting agents, and shortening the service life of structures, etc. Small size, fast construction speed, and the effect of reducing the thickness of the structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present application will be further elaborated below in conjunction with the examples.

[0030] The specific technical requirements and preparation methods are as follows:

[0031] 1. Raw material requirements

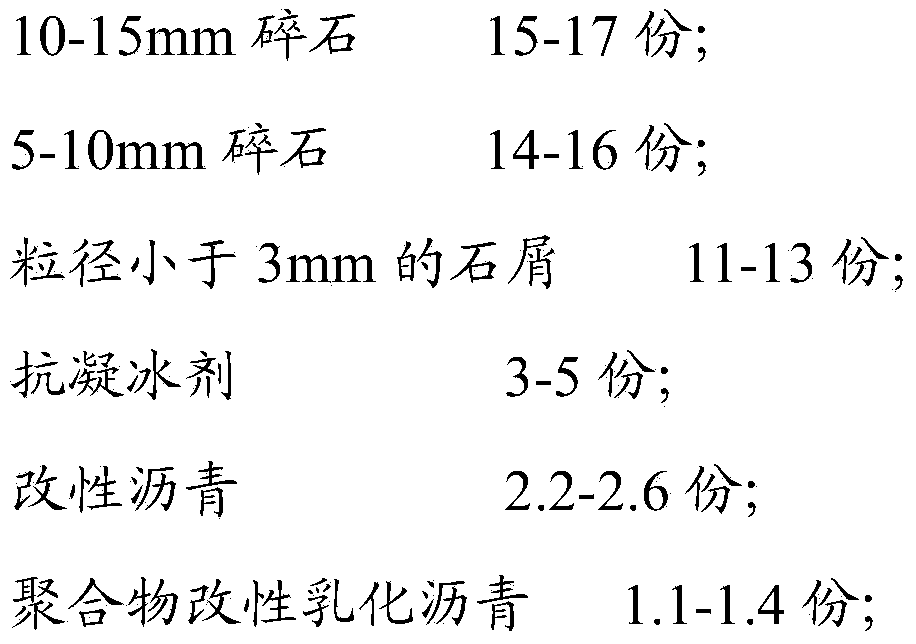

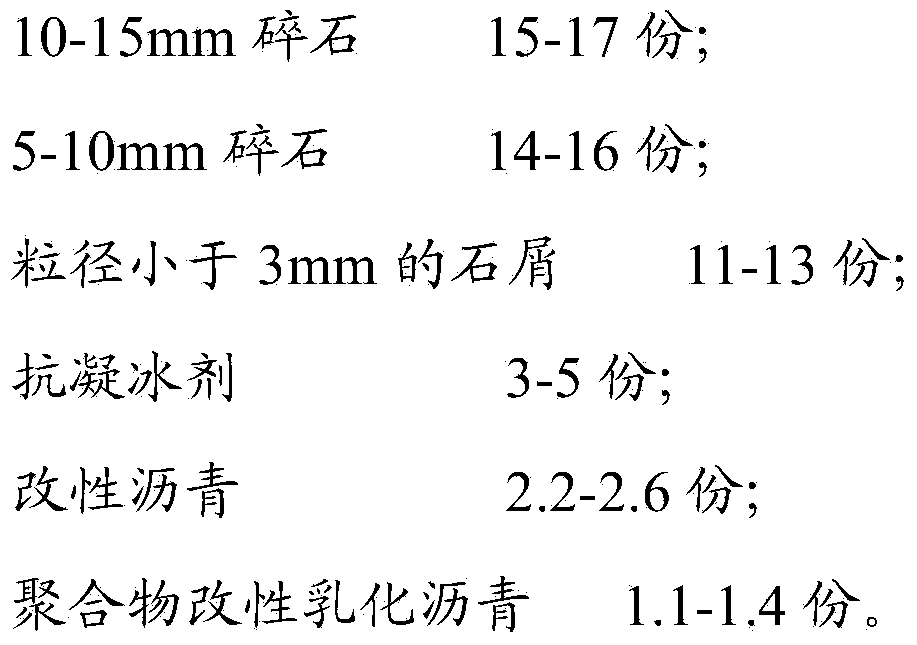

[0032] The composition of the raw materials of the anti-icing ultra-thin wearing layer pavement is as follows:

[0033]

[0034] Among them, 10-15mm crushed stone, 5-10mm crushed stone are used as coarse aggregate, stone chips with particle size less than 3mm are used as fine aggregate, anti-icing agent is used as filler, modified asphalt is used as cementing material, and polymer modified emulsified asphalt is used as layer For inter-bonding materials, the open-graded asphalt mixture design method is used, and the specific grading and material index requirements are as follows:

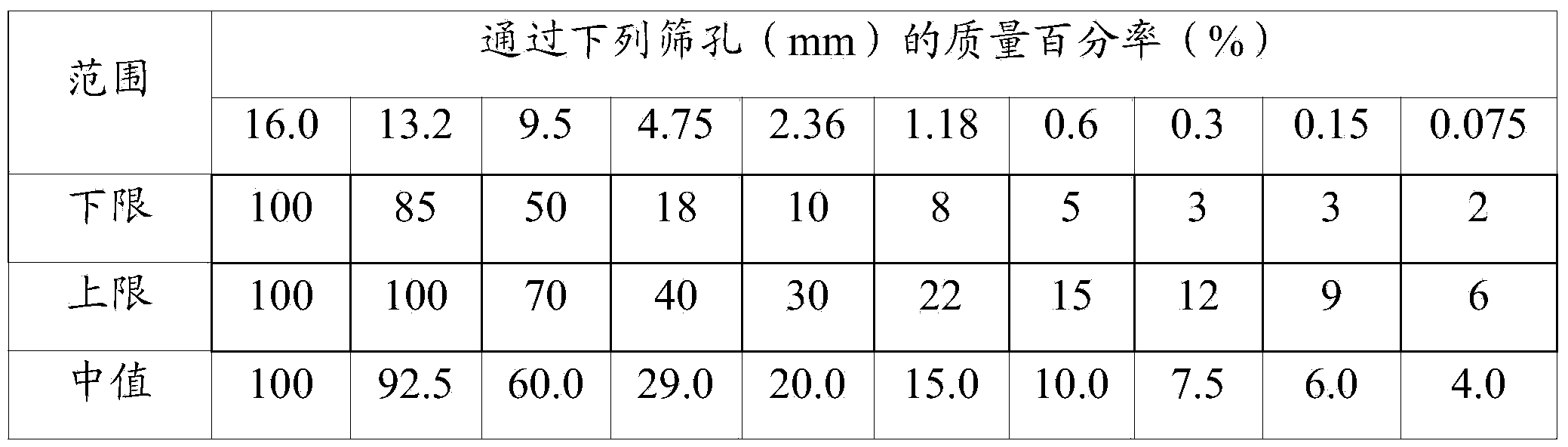

[0035] 1. Grading range

[0036] The gradation type of the anti-icing ultra-thin wear layer pavement has a large void ratio, and the surface is rough, so the pavement perform...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| voidage | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com