Impregnated white kraft paper and preparation technology thereof

A preparation process and technology of kraft paper, applied in the field of papermaking, can solve the problems of dust affecting quality, incomplete penetration, low air permeability, etc., and achieve the effects of uniform dyeing, paper cost reduction, and good tensile strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

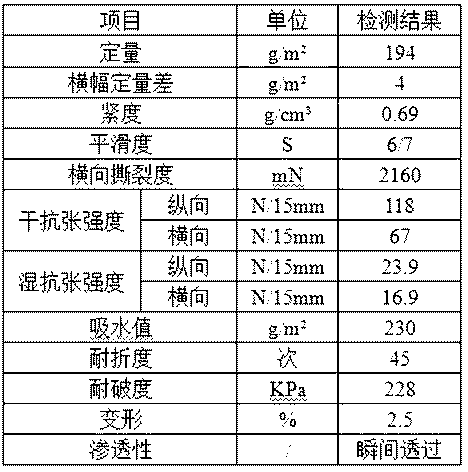

Embodiment 1

[0030] (1) Preparation of fillers for later use:

[0031] Add 6625kg of water to the filler dissolving tank, start stirring, first slowly put 1325kg of light calcium powder into the dissolving tank, then slowly put 1325kg of heavy calcium powder into the dissolving tank, ensure that the stirring time is more than 30 minutes, make it fully stirred evenly, and finally prepare the concentration Reserve for 310g / L filler.

[0032] (2) A preparation process of impregnated white kraft paper comprises the following steps:

[0033] 1. Pulping:

[0034] (1) Preparation of long-fiber pulp: the bleached kraft softwood long-fiber wood pulp with a fiber length of 2.5 mm is pulverized by a hydropulper and transferred to the tap pool, and then transferred to the long-fiber pulp through a double-disc mill beater. Tap the back pond, and control the beating power to 150kwh, the beating concentration to 4.0%, and the beating degree to 24°SR to obtain long-fiber pulp;

[0035] (2) Preparation ...

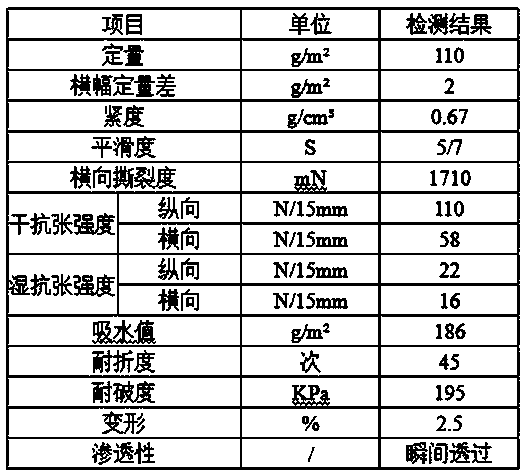

Embodiment 2

[0045] (1) Preparation of fillers for later use:

[0046] Add 6000kg of water to the filler dissolving tank, start stirring, first slowly put 1325kg of light calcium powder into the dissolving tank, then slowly put 1325kg of heavy calcium powder into the dissolving tank, ensure that the stirring time is more than 30 minutes, make it fully stirred evenly, and finally prepare the concentration Reserve for 340g / L filler.

[0047] (2) A preparation process of impregnated white kraft paper comprises the following steps:

[0048] 1. Pulping:

[0049] (1) Preparation of long-fiber pulp: the bleached kraft softwood long-fiber wood pulp with a fiber length of 2.7mm is pulverized by a hydropulper and transferred to the tap pool, and then transferred to the long-fiber pulp through a double-disc mill beater. Tap the back pond, and control the beating power to 170kwh, beating concentration is 4.3%, beating degree is 24°SR, and long-fiber pulp is obtained;

[0050] (2) Preparation of sho...

Embodiment 3

[0061] (1) Preparation of fillers for later use:

[0062] Add 6185kg of water to the filler dissolving tank, start stirring, first slowly put 1325kg of light calcium powder into the dissolving tank, then slowly put 1325kg of heavy calcium powder into the dissolving tank, ensure that the stirring time is more than 30 minutes, make it fully stirred evenly, and finally prepare the concentration Reserve for 330g / L filler.

[0063] (2) A preparation process of impregnated white kraft paper comprises the following steps:

[0064] 1. Pulping:

[0065] (1) Preparation of long-fiber pulp: the bleached kraft softwood long-fiber wood pulp with a fiber length of 2.6 mm is pulverized by a hydropulper and transferred to the tap pool, and then transferred to the long-fiber pulp through a double-disc mill beater. Tap the back pond, and control the beating power to 155kwh, the beating concentration is 4.1%, the beating degree is 25°SR, and the long fiber pulp is obtained;

[0066] (2) Prepa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| water absorption | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com