Natural luster finishing roller

A technology of ironing roller and roller body, which is used in textiles and papermaking, fabric surface trimming, etc., can solve the problems of difficult to achieve smooth erection, affect the quality of ironing, uneven fiber carding, etc., and avoid light and dark stripes and vertical stripes. , The effect of improving the quality of the scalding and improving the efficiency of the scalding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The specific technical solutions of the present invention will be further described below with reference to the accompanying drawings, so that those skilled in the art can further understand the present invention, without limiting their rights.

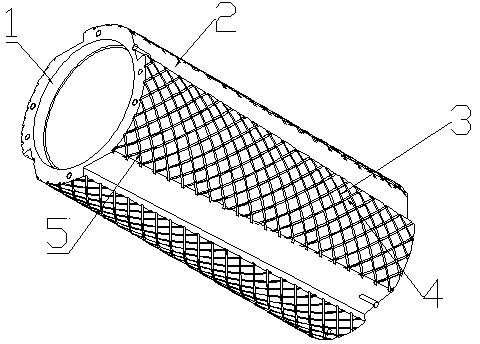

[0013] refer to figure 1 , a kind of ironing roller, comprising a roller body 1, the surface of the roller body 1 is evenly provided with several groups of beating grooves 2, each group of beating grooves 2 is composed of two helical beating blades with opposite rotation directions, and the rollers outside the beating grooves 2 The surface of the body 1 is provided with a textured roller surface formed by the crossing of several left helical grooves 3 and right helical grooves 4, and the circumferential tracks of the intersection points 5 of the left helical grooves 3 and right helical grooves 4 do not overlap with each other and are distributed sequentially In the axial direction of the ironing roller, that is, all intersectio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com