A kind of cocrpt series alloy sputtering target material and thin film and preparation method thereof

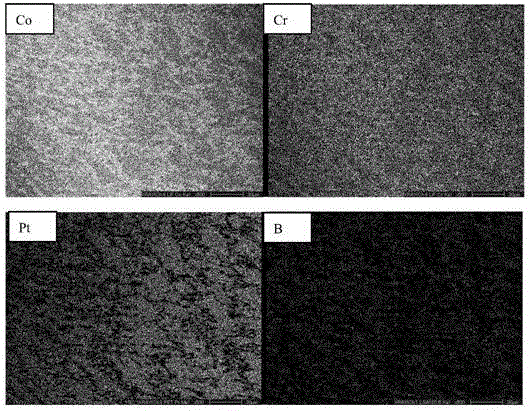

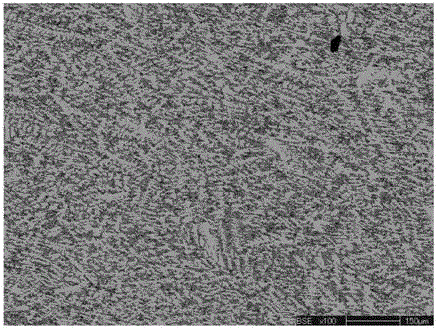

A sputtering target and alloy target technology, which is applied in sputtering coating, sputtering, metal material coating, etc., can solve the problem of low density, poor film composition uniformity, and poor chemical composition uniformity. and other problems, to achieve the effect of low content of harmful impurity elements, small and uniform grain size, and obvious non-magnetic grain boundaries

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] The Co11.5Cr22Pt10B sputtering target material of the present invention is prepared through the following steps:

[0045] (1) Raw material preparation: select Co, Cr, Pt above 3N5 and B with C content <100ppm as raw materials;

[0046] (2) Preparation of master alloy: Co prepared by vacuum induction melting method according to the nominal content of the alloy 80 B 20 (atomic percent) master alloy;

[0047] (3) Preparation of alloy ingots: use the above-mentioned master alloy, carry out batching according to the nominal composition Co11.5Cr22Pt10B, adopt vacuum induction melting method to prepare alloy ingots, first vacuumize to 1×10 -1 Below Pa, then gradually increase the temperature and start to melt the material. When the material is completely melted, pass argon gas, stop heating, and start to solidify the material. After solidifying for about 5-20 minutes, continue to heat up. When the material is completely melted, pour the ingot into the mold ;

[0048] (4) H...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com