Low-energy consumption and low-heat constant pressure system of full-hydraulic crane for ship

A technology of constant pressure system and crane, applied in the direction of fluid pressure actuation system components, mechanical equipment, fluid pressure actuation device, etc., can solve problems such as load, changeable heat, etc. that cannot be solved very effectively, and achieve high practical value and Application prospects, solution to limitations, simple manipulation effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

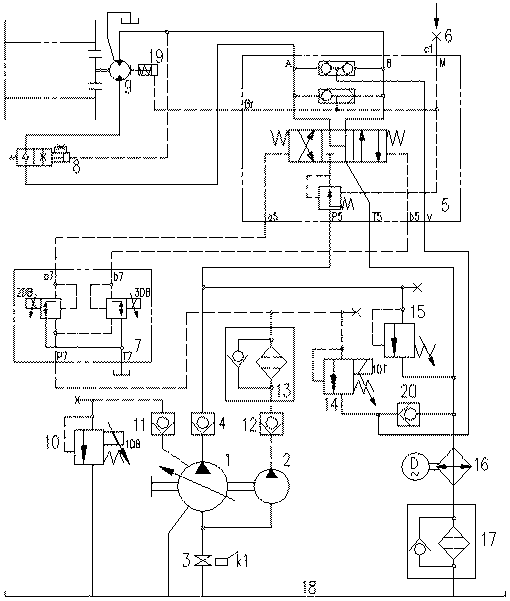

[0017] Now further illustrate how the present invention is implemented in conjunction with accompanying drawings:

[0018] The present invention is a low energy consumption and low heat constant pressure system for a marine full hydraulic crane, which is composed of a hydraulic oil pump system and an electric control system. Proportional reversing valve, electric proportional relief valve, relief valve and hydraulic oil tank form a serial pump connection system. High-pressure oil pump 1 and gear oil pump 2 suck oil from hydraulic oil tank 18 through oil suction stop valve 3; high-pressure oil pump 1 passes through check valve 4 , and connected to the oil inlet P5 of the hydraulic control proportional reversing valve 5 and the relief valve 15, the remote pressure adjustment oil port of the oil pump 1 enters the oil inlet of the proportional relief valve 10 through the check valve 11, and the proportional relief valve 10 The leaked oil directly flows back to the hydraulic oil ta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com