Passenger car assembly line

An assembly line and passenger car technology, applied in assembly machines, metal processing equipment, manufacturing tools, etc., can solve the problems of large amount of civil engineering, large investment, long implementation period, etc. The effect of short implementation time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

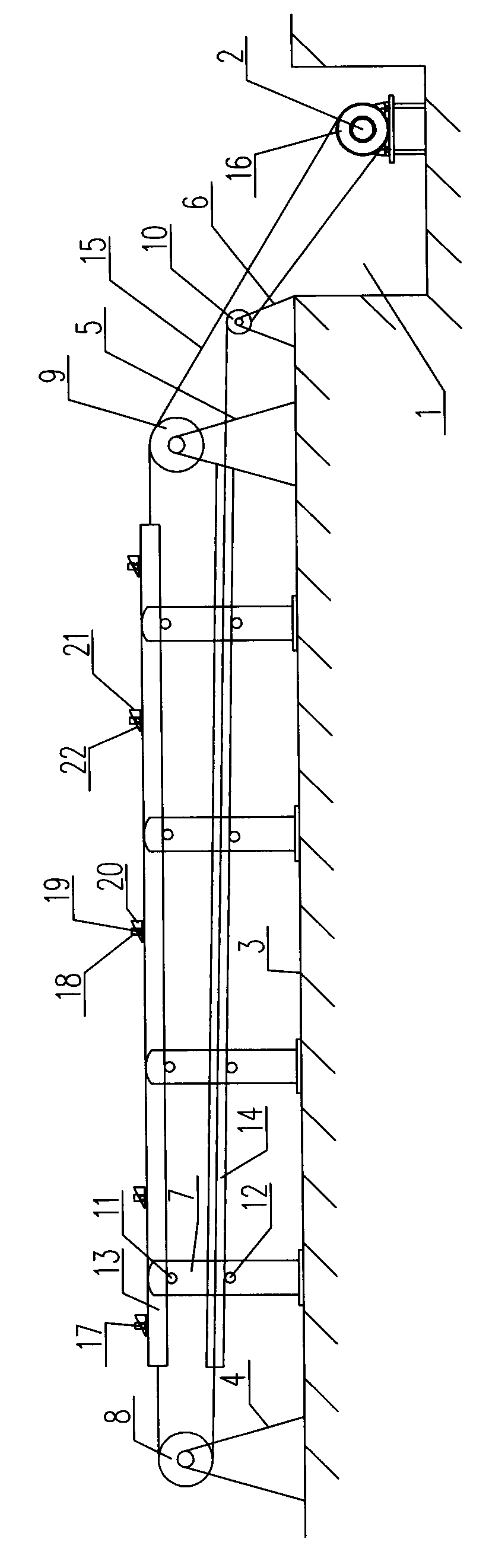

[0008] The specific content of the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0009] like figure 1 As shown, the passenger car assembly line includes: a deceleration drive device 2 arranged in the ground pit 1, a first sprocket support frame 4, a second sprocket support frame 5, and a third sprocket support frame arranged on the ground 3 6 and several guide support seats 7 arranged between the first sprocket support frame 4 and the second sprocket support frame 5, on which the first sprocket support frame 4 is provided with a first sprocket 8, in the The second sprocket support frame 5 is provided with a second sprocket 9, a third sprocket 10 is provided on the third sprocket support frame 6, and upper guides are respectively provided on the plurality of guide support seats 7. Wheel 11 and lower guide wheel 12, on described upper guide wheel 11, be supported with push-pull rod 13, on described ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com