Method for absorbing paint mist by utilizing nanometer calcium carbonate

A technology of nano-calcium carbonate and paint mist, which is applied to the surface coating liquid device, spray device, coating, etc., can solve the problems of limited service life of activated carbon and increase cost, so as to reduce usage, save cost, improve The effect of adsorption capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] At first principle of the present invention and working process are described as follows:

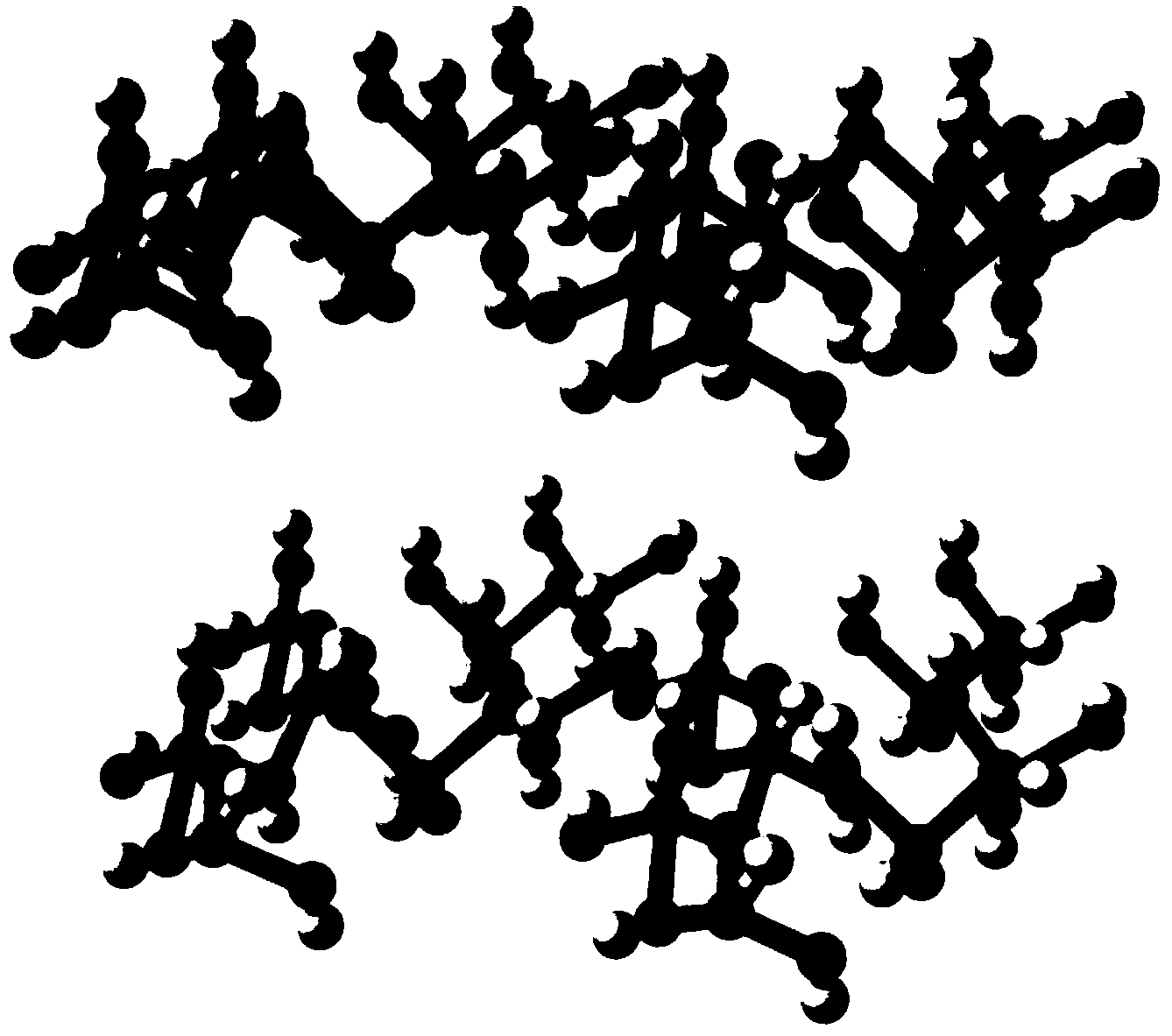

[0031] Nano-calcium carbonate is a nano-scale porous substance with a highly developed pore structure. Its specific microstructure schematic diagram is as follows: figure 1 shown. Due to the superfineness of calcium carbonate particles, its crystal structure and surface electronic structure change, resulting in the quantum size effect, small size effect, surface effect and macroscopic quantum effect that ordinary calcium carbonate, that is, limestone does not have. At the same time, the porous structure of nano-calcium carbonate makes it have a huge specific surface area. When it is used to filter and adsorb paint mist, it can make full contact between nano-calcium carbonate and paint mist, thereby improving the adsorption performance of nano-calcium carbonate to paint mist. . And the pore size of nano-calcium carbonate can be adjusted between 10nm and 100nm through the formula...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com