An associated gas condensate recovery device

A technology of recovery device and associated gas, which can be used in combined devices, gas fuel, petroleum industry, etc., and can solve problems such as incomplete gas-liquid separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

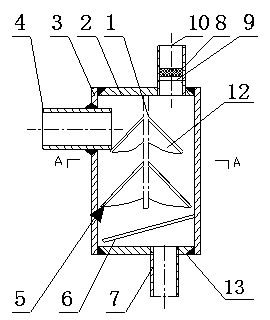

[0022] In order to overcome the defect of incomplete gas-liquid separation in the existing associated gas condensate recovery device, this embodiment provides a figure 1 , 2 The associated gas condensate recovery mechanism shown includes a cylinder body 3, an upper end cap 2 welded to the upper end surface of the cylinder body 3 and a lower end cap 13 welded to the upper end surface of the cylinder body 3, and a lower end cap 13 welded to the upper part of the outer wall of the cylinder body 3 and penetrating through the transverse direction of the cylinder body 3. The air inlet pipe 4, the longitudinal air outlet pipe 10 arranged on the upper end head 2 away from the horizontal air inlet pipe 4 and passing through the upper end head 2, the longitudinal liquid discharge pipe 7 arranged at the bottom of the lower end head 13 and the branch pipe arranged in the cylinder body 3 Liquid plate 5. A vertical baffle 1 extending longitudinally downward is provided on the inner surface...

Embodiment 2

[0024] On the basis of Embodiment 1, this embodiment provides such as figure 1 , 2 The liquid separator 5 on the same surface of the baffle plate 1 shown in .3 is composed of at least two fan-shaped steel plates 12, and the angle between the two planes of the two fan-shaped steel plates 12 is greater than zero and less than 180 degrees. The multi-layer inclined liquid separator 5 can ensure that the associated gas undergoes multiple collisions in the cylinder 3, thereby separating more liquid carried in the gas. The inclined design ensures that the separated liquid flows down smoothly, avoiding the Retention of fluid on the surface causes secondary entrainment of gas. Production practice has proved that when the angle between the fan-shaped steel plate 12 and the baffle plate is 45° and the angle between the bottom surfaces of the two fan-shaped steel plates 12 is 120°, the best liquid separation effect can be achieved.

[0025] The radius of the multi-stage liquid separator...

Embodiment 3

[0030] On the basis of Embodiment 1, this embodiment provides such as Figure 4 The single liquid separator plate 5 on the same side of the baffle plate 1 shown is made of a steel plate formed by hot simmering, and the liquid separator plate 5 is provided with a raised edge 16 intersecting with the baffle plate, and the raised edge 16 will separate the liquid The plate 5 is divided into a first liquid separation plate 14 and a second liquid separation plate 15 with the raised edge 16 as the axis of symmetry, and the angle between the first liquid separation plate 14 and the second liquid separation plate 15 is greater than zero and less than 180 degrees . Production practice has proved that when the angle between the separator plate 5 and the baffle is 45° and the angle between the first separator plate 14 and the second separator plate 15 is 120°, the best liquid separation effect can be achieved.

[0031] The positional relationship of up, down, left and right mentioned abo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com