A kind of extraction method and extraction agent used in the denitrification process in H acid production process

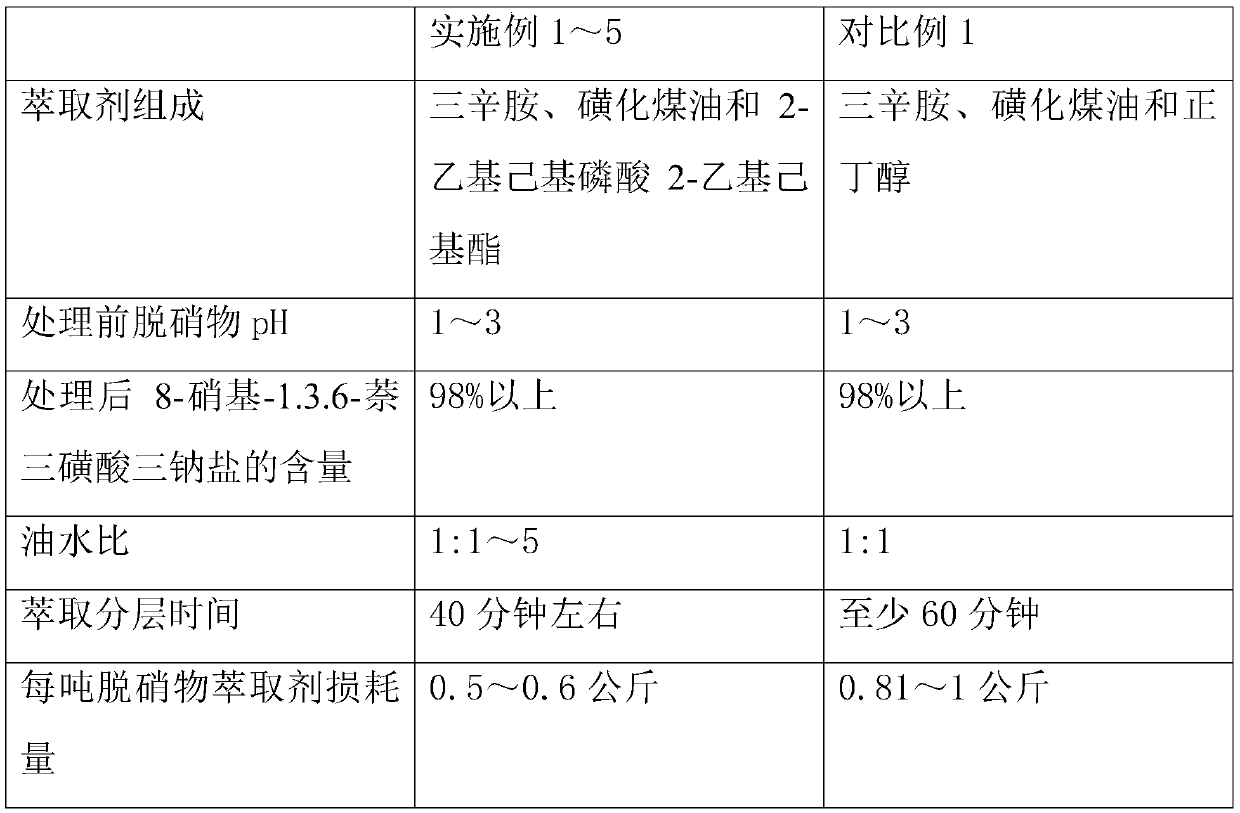

An extraction agent and extraction technology, which are applied in the direction of liquid solution solvent extraction, etc., can solve the problems of difficulty in stratification, low extraction rate, and the cost of regeneration and utilization of the phase-entrained extractant, and achieve easy stratification, high extraction rate, and simple extraction method. easy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] The high-efficiency extractant is made by mixing 1500ml of trioctylamine, 4000ml of sulfonated kerosene and 500ml of 2-ethylhexyl 2-ethylhexylphosphate ternary component, and the mixing volume ratio is 1.5:4:0.5.

[0051] Using the above-mentioned high-efficiency extractant to extract the H acid denitrification, the specific steps are:

[0052] 1) According to the existing H acid process sulfonation, continuous nitration and denitrification to obtain denitrification products containing 8-nitro-1.3.6-naphthalenetrisulfonic acid and a large amount of inorganic acids, the pH of the denitrification products is 2.

[0053] 2) Transfer 12,000ml of the denitrated product from step 1) into the extraction container, then add the high-efficiency extractant compounded above, start stirring, and stir for 10 minutes at a speed of 30 rpm and a temperature of 45°C.

[0054] 3), the mixed material obtained in step 2) is left to stand for 40 minutes, the upper layer is the organic phase...

Embodiment 2

[0068] The high-efficiency extractant is mixed with 1500ml of trioctylamine, 3000ml of sulfonated kerosene and 200ml of 2-ethylhexyl 2-ethylhexylphosphate ternary component, and the mixing volume ratio is 1.5:4:0.5.

[0069] Using the above-mentioned high-efficiency extractant to extract the H acid denitrification, the specific steps are:

[0070] 1) According to the existing H acid process sulfonation, continuous nitration and denitrification to obtain denitrification products containing 8-nitro-1.3.6-naphthalenetrisulfonic acid and a large amount of inorganic acids, the pH of the denitrification products is 2.

[0071] 2) Transfer 4700ml of the denitrated product from step 1) into the extraction container, then add the high-efficiency extractant compounded above, start stirring, and stir for 10 minutes at a speed of 30 rpm and a temperature of 45°C.

[0072] 3), the mixed material obtained in step 2) is left to stand for 40 minutes, the upper layer is the organic phase, and ...

Embodiment 3

[0077] The high-efficiency extractant is mixed with 1500ml of trioctylamine, 5000ml of sulfonated kerosene and 800ml of 2-ethylhexyl 2-ethylhexylphosphate ternary component, and the mixing volume ratio is 1.5:4:0.5.

[0078] Using the above-mentioned high-efficiency extractant to extract the H acid denitrification, the specific steps are:

[0079] 1), according to the existing H acid process sulfonation, continuous nitration and denitrification to obtain the denitrification product containing 8-nitro-1.3.6-naphthalene trisulfonic acid and a large amount of inorganic acid, the pH of the denitrification product is 2.5.

[0080] 2) Transfer 36,500ml of the denitrated product from step 1) into the extraction container, then add the high-efficiency extractant compounded above, start stirring, and stir for 10 minutes at a speed of 30 rpm and a temperature of 45°C.

[0081] 3), the mixed material obtained in step 2) is left to stand for 40 minutes, the upper layer is the organic phase,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com