A fully automatic cleaning system for edible fungi and its application method

A technology for fully automatic cleaning and edible fungi is applied in the field of fully automatic cleaning systems for edible fungi to achieve the effect of convenient cleaning of dirt, increased cleaning effect, and good effect of dirt treatment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

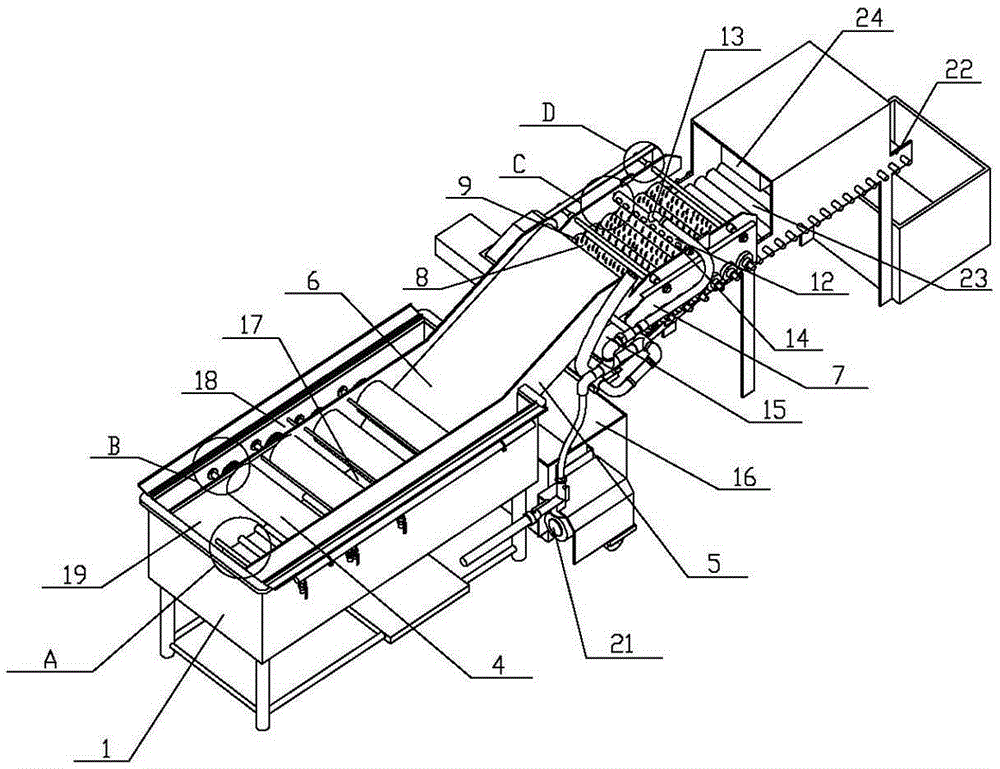

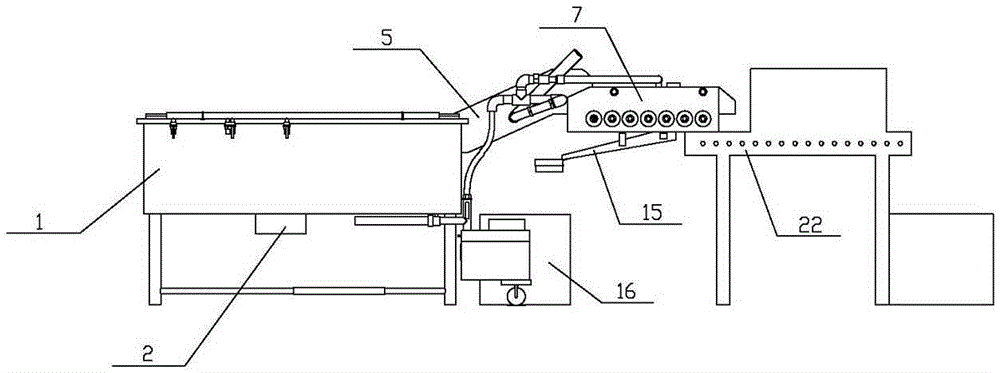

[0025] The present invention will be further described below in conjunction with accompanying drawing:

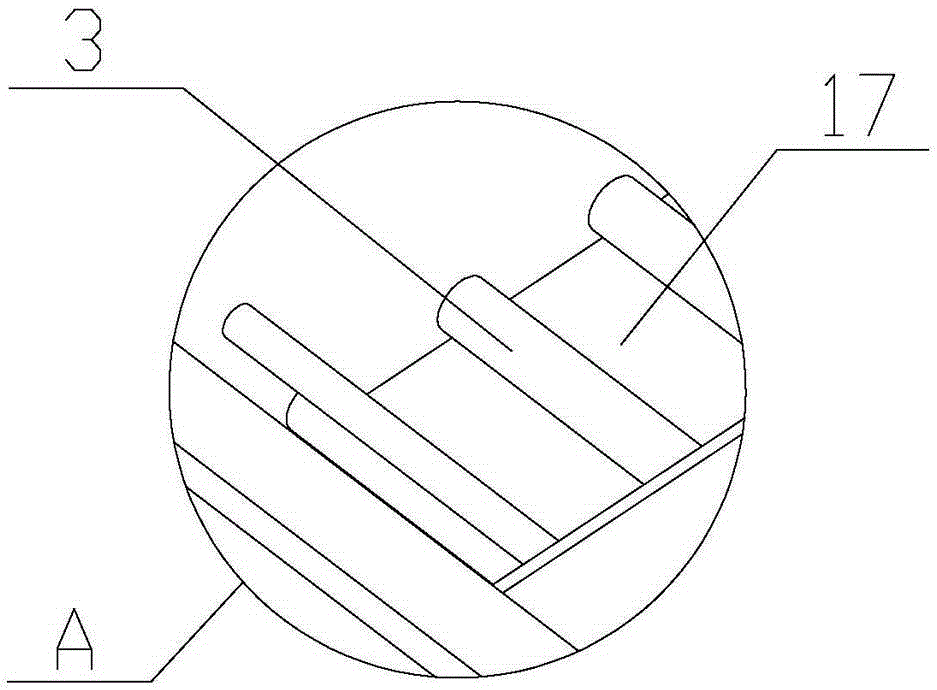

[0026] With reference to accompanying drawing, this edible mushroom automatic cleaning system comprises a cleaning tank 1, and an ultrasonic generator 2 is installed on the bottom outer wall of the cleaning tank 1, and a group of ultrasonic transducers 3 are connected on the ultrasonic generator 2, and the ultrasonic transducer The device 3 is installed on the bottom of the cleaning tank 1, and a group of rolling brushes 4 that rotate in the cleaning tank 1 are installed in the cleaning tank 1. The two ends of the rolling brushes 4 are respectively connected to the two inner walls of the cleaning tank 1. Two adjacent rolling brushes 4 are arranged in a staggered arrangement.

[0027] One side of the cleaning tank 1 is connected with a conveyor frame 5, the conveyor frame 5 penetrates into the side of the cleaning tank 1 and is fixedly connected to the cleaning tank 1, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com