Fiber product provided with water repellant coating layer and method for manufacturing the fiber product

A fiber product, waterproof coating technology, applied in the direction of liquid repellent fiber, plant fiber, fiber treatment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

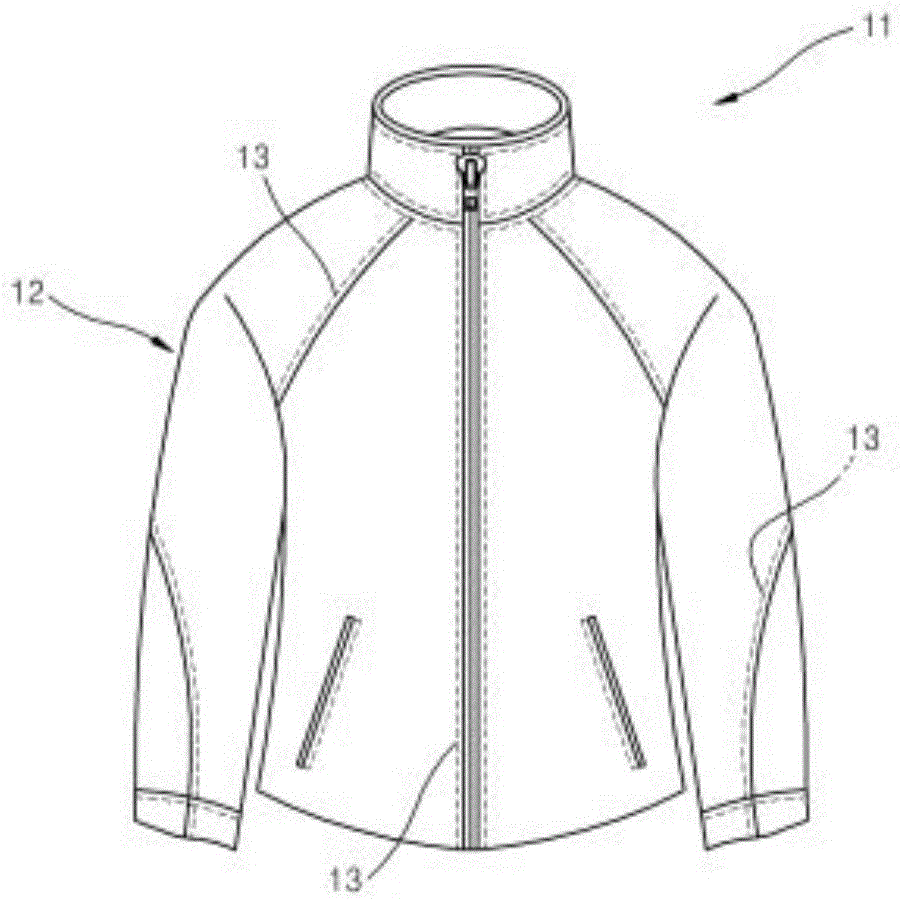

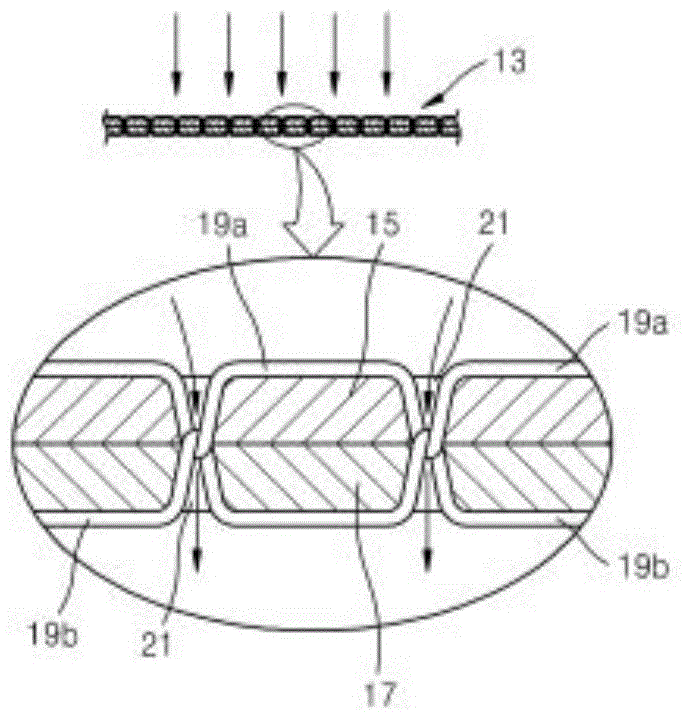

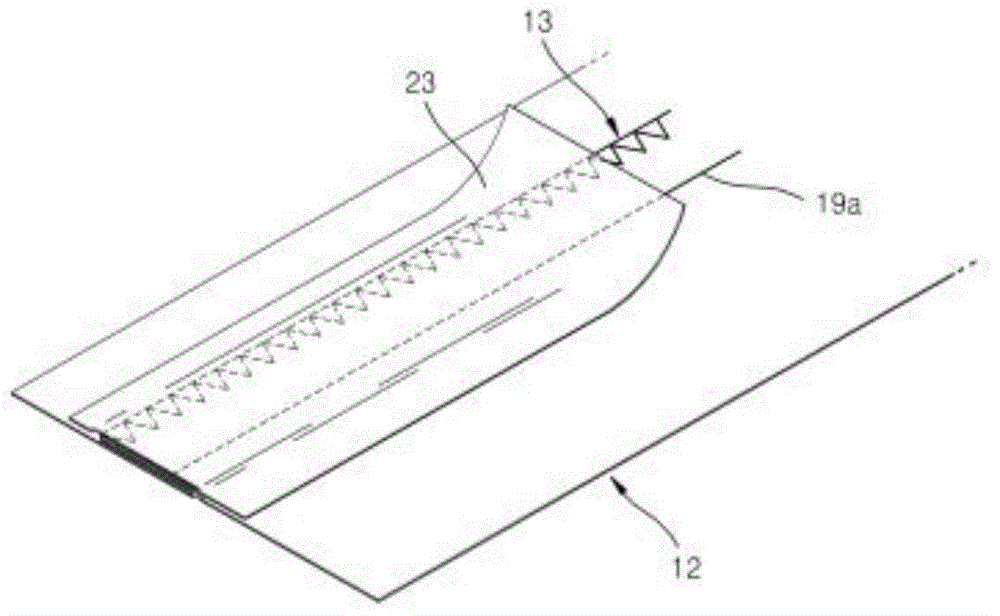

[0069] Hereinafter, various embodiments according to the present invention will be described in more detail with reference to the attached drawings.

[0070] Fundamentally speaking, the present invention is for: the semi-finished product made of fabric containing natural fiber, and the semi-finished product made of synthetic fiber fabric, carry out waterproof treatment by the different methods that will be stated below, make the fabric made of natural fiber The finished semi-finished product is waterproof, and the semi-finished product made of natural synthetic fiber fabric can not only be waterproof, but also can strengthen the waterproof ability.

[0071] The following will be stated, according to the first to the fifth embodiment of the present invention, the manufacturing method of the fiber product forming the waterproof coating is about: the fiber semi-finished product made of natural fiber fabric as the main material, through various Method After waterproof treatment, t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| dehydration rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com