Electric heating tube having sealing porcelain head with electric heating tube sleeve

An electric heating tube and porcelain head technology, applied in the field of electric heating tubes, can solve the problems of short circuit of the power supply of the bracket board, the structure is not compact enough, the structure of the wiring end of the electric heating tube is too long, etc., and achieves the effects of good insulation and sealing and improved safety performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] specific implementation

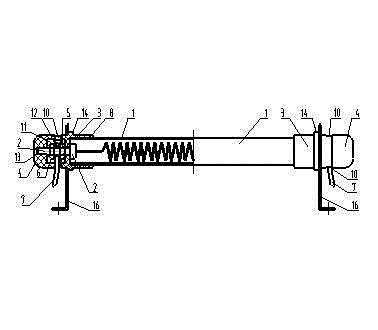

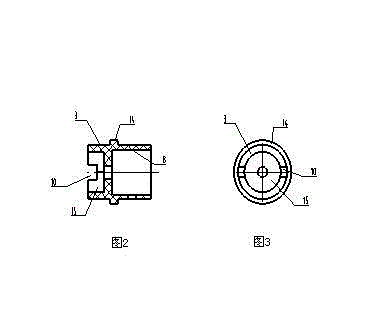

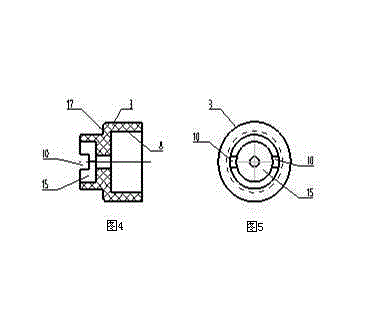

[0020] The present invention is mainly composed of electric heating tube 1, wiring screw 2, porcelain head 3, porcelain head cover 4, mounting nut 5, crimping nut 6, and crimping washer 12. The electric heating tube 1 is a variety of electric heating tubes with wiring screws, such as Quartz electric heating tube, stainless steel electric heating tube, etc., the electric heating tube 1 terminal is provided with the porcelain head 3 which is integrated with the electric heating tube sleeve 8 and the cavity 15, so that there is no cross-sectional gap between the porcelain head 3 and the electric heating tube 1, and the inner end of the porcelain head 3 The electric heating tube sleeve 8 covers the electric heating tube 1, and the cavity 15 at the outer end of the ceramic head 3 contains the mounting nut 5, the power cord 7 and the crimping washer 12, and the outer edge of the cavity 15 is provided with a power cord for leading out the power cord ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com