In cell touch panel and display device

An embedded touch screen, consistent technology, applied in optics, instrumentation, electrical digital data processing, etc., can solve the problems of large number of peripheral traces, unfavorable narrow frame design, large touch blind area, etc., to reduce the disadvantages of narrow The probability of occurrence of problems such as frame design and relatively large touch blind area, the reduction of the number of wires, and the effect of reducing the number of wires

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

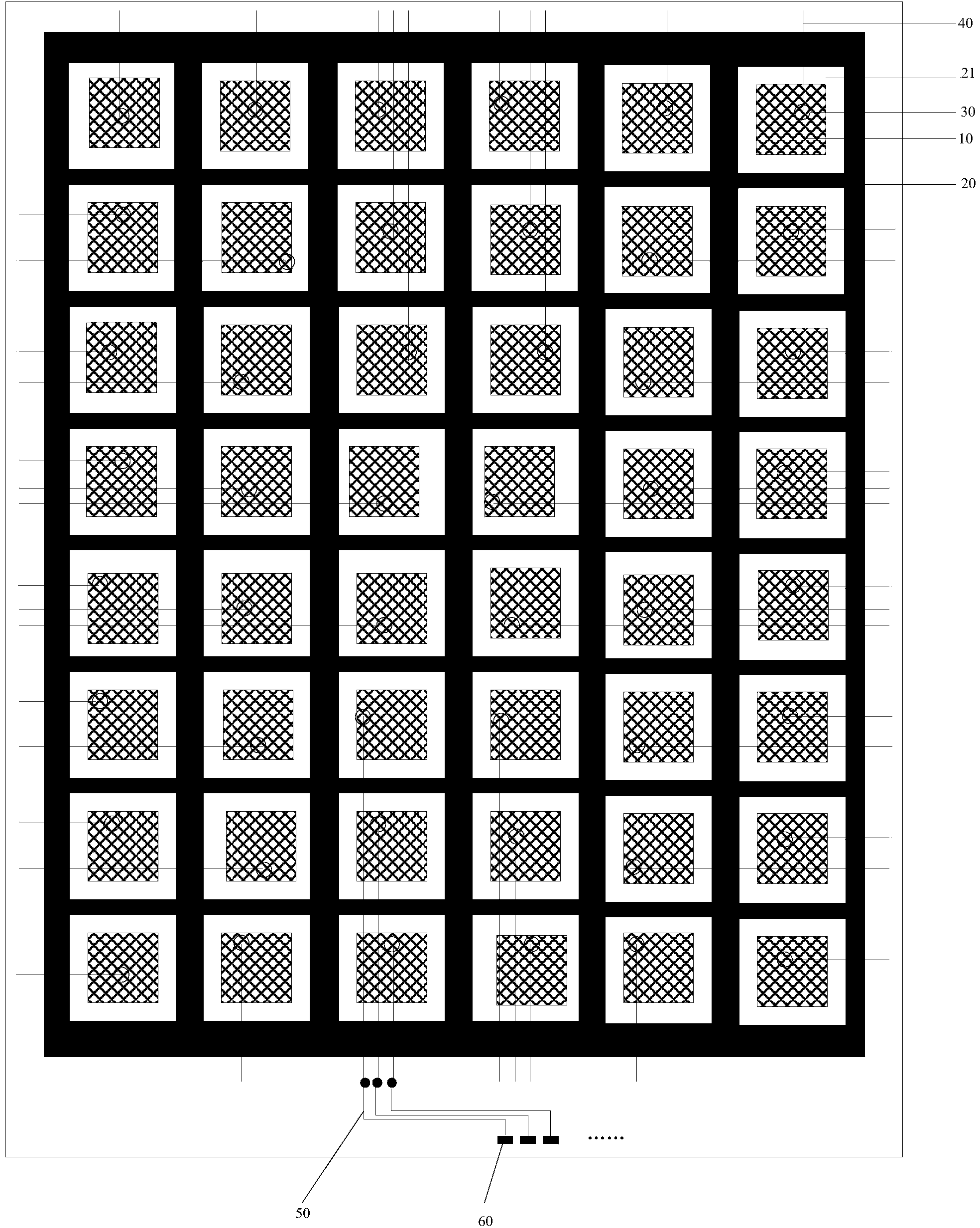

[0120] In the first embodiment of the present invention, the combination of Figure 2a , to explain the principle of solving the problem of reducing the number of self-capacitance electrodes in the embodiment of the present invention.

[0121] Such as Figure 2a As shown, the embedded touch screen of the embodiment of the present invention includes:

[0122] A conductive layer 20 comprising a plurality of hollow areas 21 arranged in a matrix; wherein, Figure 2a It is illustrated by taking 8 rows and 6 columns and a total of 48 hollow areas 21 as an example;

[0123] A plurality of self-capacitance electrodes 10 arranged on the same layer as the conductive layer 20 and mutually insulated from the conductive layer 20; wherein, each of the hollowed out regions 21 is provided with one self-capacitance electrode 10; Figure 2a It is illustrated by taking a total of 48 self-capacitance electrodes 10 in 8 rows and 6 columns as an example;

[0124] A plurality of non-intersecting...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com