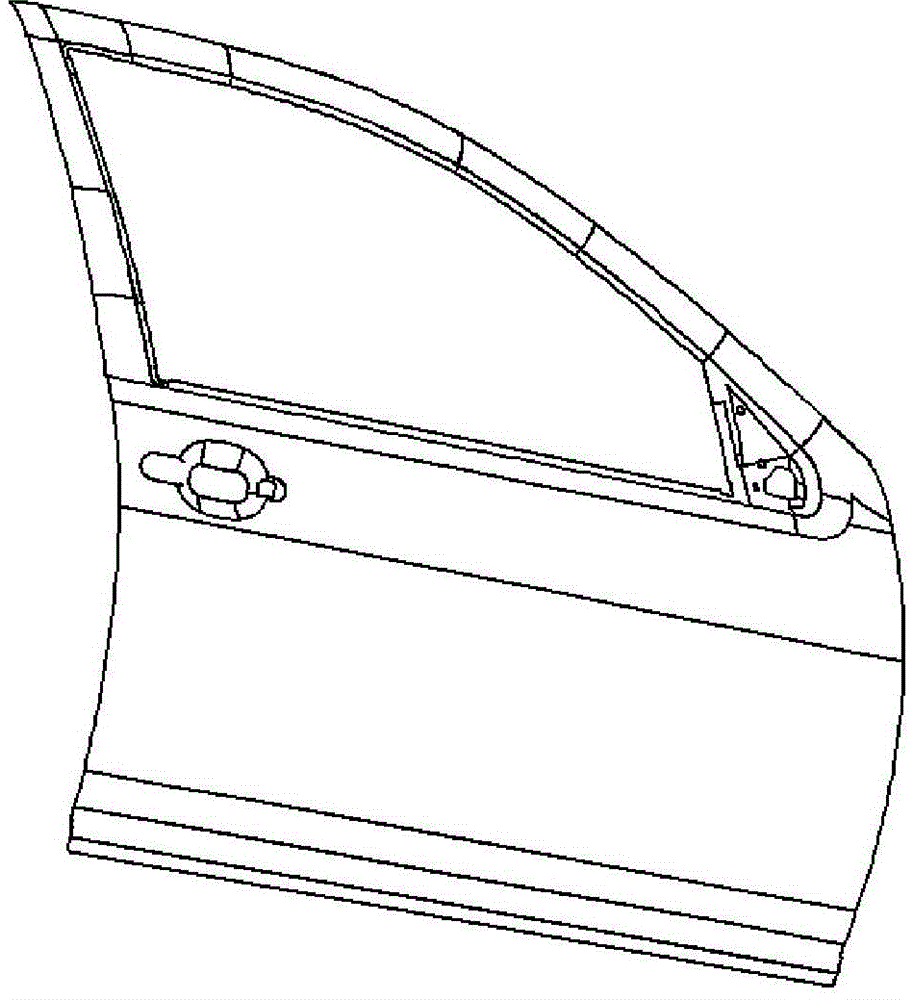

Auto-positioning device for visual inspection of exterior body panels

A technology for visual inspection and outer cover, applied in the field of workpiece automation fixtures, can solve the problems of narrow detection range, low precision, slow detection speed, etc., and achieve the effect of fast positioning speed, high precision and improved detection efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention is described in detail below in conjunction with accompanying drawing:

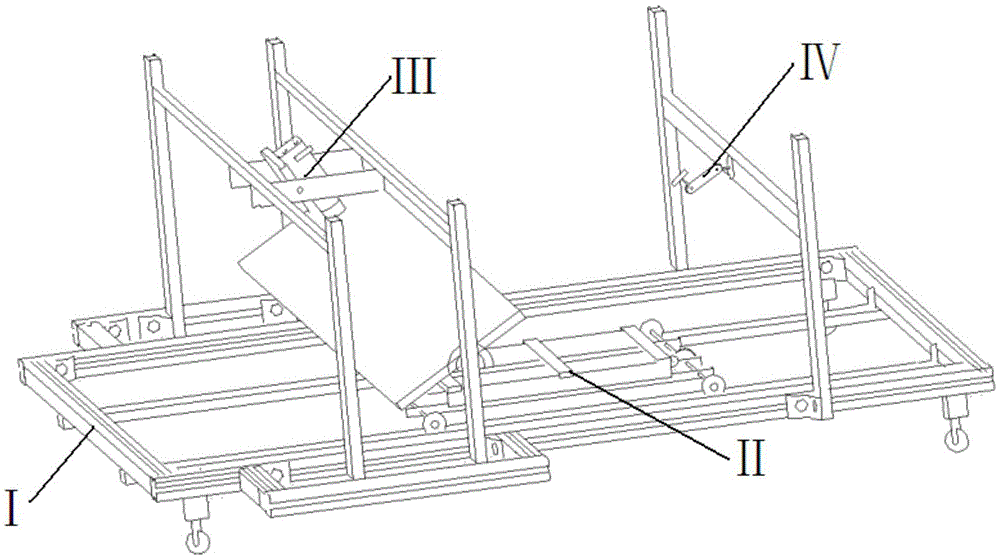

[0038] refer to figure 2 , The auto-positioning device for visual detection of the outer cover of the automobile according to the present invention is composed of a base I, a power unit II, an image acquisition system III, and a laser emitter assembly IV. The base I is the assembly base of the automatic positioning device for the visual inspection of the entire automobile outer cover, the power device II is installed on the power guide rail of the base I, and the image acquisition system III and the laser transmitter assembly IV are respectively installed on the bottom of the base I. on the brackets on the left and right sides.

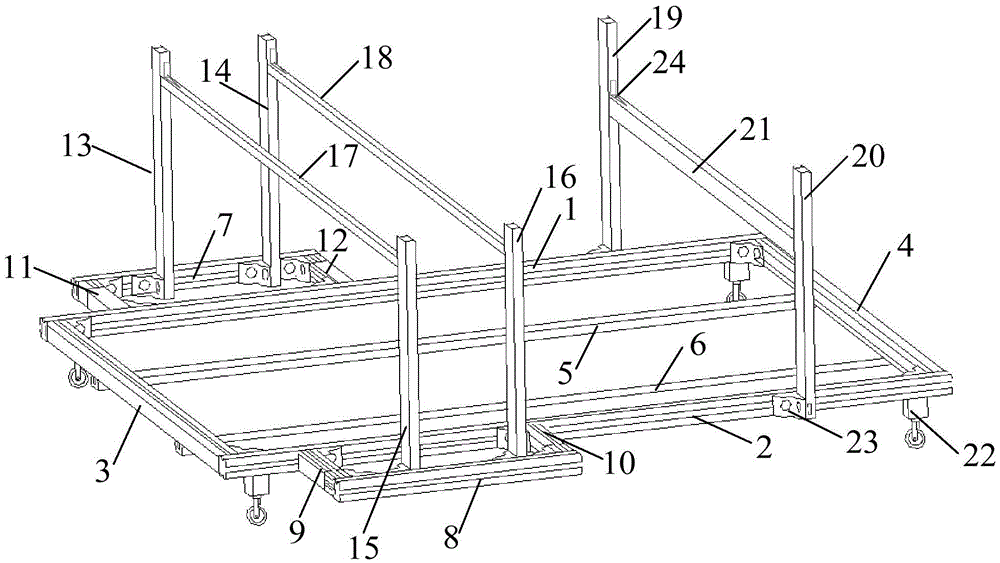

[0039] refer to image 3 and Figure 10 , the base I includes a pedestal, an image acquisition system bracket, a laser transmitter assembly bracket, 32 wide-angle irons 23 with the same structure and 16 narrow-angle irons 24 with the same structur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com