Saturated salt water drilling fluid for deep well salt mine drilling and preparation method of drilling fluid

A brine drilling fluid and brine technology, applied in the direction of chemical instruments and methods, drilling compositions, etc., can solve the problems of suspended rock dust and fluidity deterioration, pitting stress of drill string, and enhanced corrosion effect of electrolyte on drilling tools, etc. , to achieve excellent salt resistance and suspension performance, good rheological effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

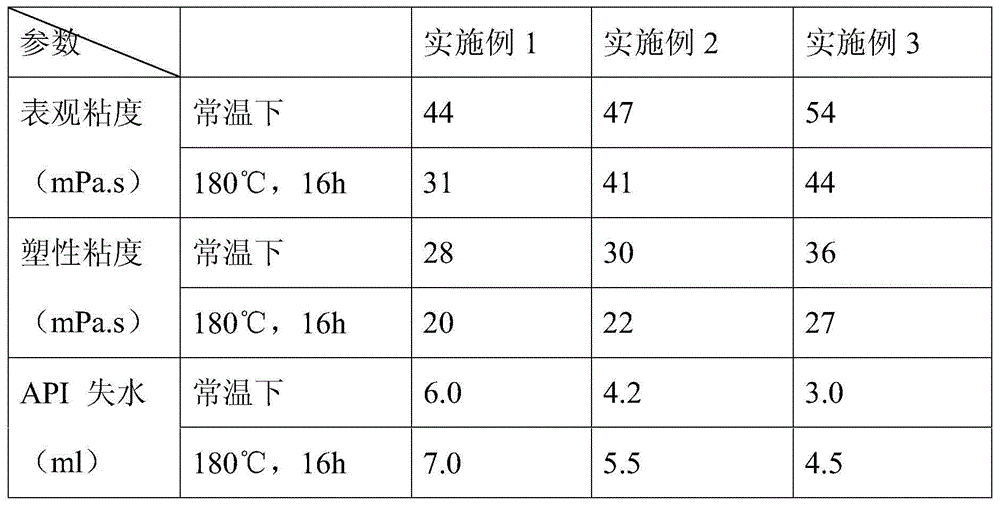

Embodiment 1

[0033] Measure 100ml of tap water, add 0.2g of sodium carbonate under low-speed stirring to dissolve, then slowly add 2g of bentonite under low-speed stirring at 4000rpm, stir for 10 minutes, then add 2g of sepiolite under low-speed stirring at 4000rpm, After stirring for 10 minutes, continue to add 0.5 g of hectorite, stir for 20 minutes, and prehydrate at room temperature and pressure for 24 hours. Then add 0.5 grams of sulfonated asphalt powder (FT-1) under electric high-speed stirring, stir for 10 minutes, add 0.4 grams of salt-resistant copolymer GTQ, stir for 10 minutes, add 0.3 grams of potassium humate (KHm), and stir for 10 minutes Minutes, add 0.1 g of sodium hydroxide, add 2 g of inorganic salt magnesium chloride, 130 g of sodium chloride and 7.0 g of potassium chloride, stir for 10 minutes, add 1.0 g of inorganic salt recrystallization inhibitor, stir for 10 minutes, add water-based disinfectant Foam agent 0.1 g, stirred for 10 minutes. Finally, the saturated brin...

Embodiment 2

[0035] Measure 100ml of tap water, add 0.4g of sodium carbonate under low-speed stirring to dissolve, then slowly add 4g of bentonite under low-speed stirring at 4000 rpm, stir for 10 minutes, then add 1g of sepiolite under low-speed stirring at 4000 rpm, After stirring for 10 minutes, continue to add 0.8 g of laponite, stir for 20 minutes, pre-hydrate at room temperature and pressure for 24 hours, then add 1.0 g of sulfonated asphalt powder (FT-1) under electric high-speed stirring, stir for 10 minutes, add 1.0 grams of salt-resistant copolymer GTQ, stirred for 10 minutes, added 0.3 grams of potassium humate (KHm), stirred for 10 minutes, added 5.0 grams of inorganic salt magnesium chloride, 25 grams of sodium chloride and 10 grams of potassium chloride, and stirred for 10 minutes , adding 0.8 g of inorganic salt recrystallization inhibitor, stirring for 10 minutes, adding 0.6 g of water-based defoamer, stirring for 10 minutes, to obtain deep well brine drilling saturated brin...

Embodiment 3

[0037]Measure 100ml of tap water, add 1.0g of sodium carbonate under low-speed stirring to dissolve, then slowly add 4g of bentonite under low-speed stirring at 4000 rpm, stir for 10 minutes, then add 0.5g of sepiolite under low-speed stirring at 4000 rpm, After stirring for 10 minutes, continue to add 1.0 g of hectorite, stir for 20 minutes, and pre-hydrate at room temperature and pressure for 24 hours. Then add 4.0 grams of sulfonated asphalt powder (FT-1) under electric high-speed stirring, stir for 10 minutes, add 2.0 grams of salt-resistant copolymer GTQ, stir for 10 minutes, add 0.3 grams of potassium humate (KHm), and stir for 10 minutes Minutes, add 5.0 grams of inorganic salt magnesium chloride, 20 grams of sodium chloride and 15 grams of potassium chloride, stir for 10 minutes, add 0.5 grams of inorganic salt recrystallization inhibitor, stir for 10 minutes, add 0.4 grams of water-based defoamer, stir for 10 minutes Minutes to obtain saturated brine drilling fluid fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com