Water-based anticorrosive finish paint for vehicle plate springs and chassis

A leaf spring and chassis technology, which is applied in the field of one-component water-based anti-corrosion topcoat, can solve the problems of curing, material waste, equipment pipeline blockage, etc., and achieve the effect of convenient use, good compatibility, and reduced use and emission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

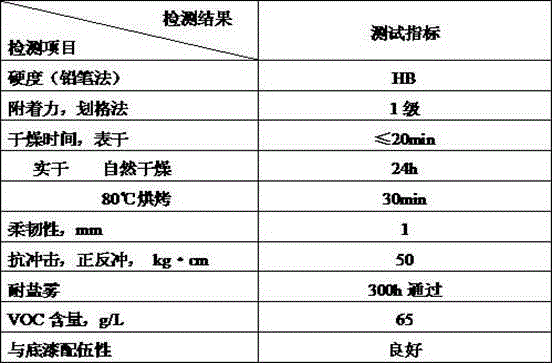

Image

Examples

Embodiment 1

[0014] The water-based anti-corrosion finish paint that is used for metal parts such as vehicle leaf spring and chassis described in the present embodiment, color is medium gray, and its preparation method comprises the following steps:

[0015] (1) Mix 18 parts of deionized water, 0.6 parts of wetting and dispersing agent, 0.2 parts of polysiloxane defoamer, 0.1 part of preservative, 0.6 part of anti-flash rust agent, 6 parts of film-forming aid, and 1.4 parts of propylene glycol , 0.2 parts of PH value regulator, 10 parts of iron oxide black pigment, 5 parts of rutile titanium dioxide, 9 parts of functional filler, put them into the container in turn under stirring state, mix for 5-10 minutes, and then mix at 800-1200 rpm Disperse at high speed for 30-50 minutes at high speed to prepare mixed slurry for later use;

[0016] (2) Use a grinder to grind the prepared mixed slurry to a fineness below 50 microns, and make a pigment slurry for later use;

[0017] (3) Add 48 parts o...

Embodiment 2

[0019] The water-based anti-corrosion finish paint used for metal parts such as vehicle leaf springs and chassis described in this embodiment is black in color. Its preparation method comprises the following steps:

[0020] (1) Mix 15 parts of deionized water, 0.8 parts of wetting and dispersing agent, 0.2 parts of polysiloxane defoamer, 0.2 part of preservative, 0.5 part of anti-flash rust agent, 7 parts of film-forming aid, and 1.2 parts of propylene glycol , 0.2 parts of PH value regulator, 8 parts of iron oxide black pigment, 2 parts of carbon black pigment, and 8 parts of functional filler, put them into the container in turn under stirring state, mix for 5-10 minutes, and then mix at 800-1200 rpm Disperse at high speed for 30-50 minutes at high speed to prepare mixed slurry for later use;

[0021] (2) Use a grinder to grind the prepared mixed slurry to a fineness below 50 microns, and make a pigment slurry for later use;

[0022] (3) Add 56 parts of water-based epoxy-m...

Embodiment 3

[0024] The water-based anti-corrosion finish paint that is used for metal parts such as vehicle leaf spring and chassis described in the present embodiment, color is light blue, and its preparation method comprises the following steps:

[0025] (1) Mix 10 parts of deionized water, 0.5 parts of wetting and dispersing agent, 0.1 part of polysiloxane defoamer, 0.1 part of preservative, 0.4 part of anti-flash rust agent, 8 parts of film-forming aid, and 1 part of propylene glycol , 0.1 part of PH value adjuster, 14.5 parts of titanium dioxide pigment, 0.1 part of phthalocyanine blue pigment, 0.3 part of iron oxide yellow, 5 parts of functional filler, put them into the container in turn under stirring state, mix for 5-10 minutes, and then mix at 800 - Disperse at high speed for 30-50 minutes at a speed of 1200 rpm to prepare a mixed slurry for later use;

[0026] (2) Use a grinder to grind the prepared mixed slurry to a fineness below 50 microns, and make a pigment slurry for late...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com