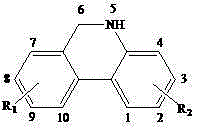

5,6-dihydrophenanthine compound and preparation method thereof

A technique for dihydrophenanthidine and compounds, applied in the field of 5,6-dihydrophenanthidine compounds and their preparation, achieving the effects of wide substrate range, high yield, and simple and easy-to-obtain catalysts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] Embodiment 1: the preparation of 5,6-dihydrophenanthidine

[0018] Under the protection of inert gas (such as high-purity nitrogen), add 1.0mmol o-bromobenzyl alcohol, 1.2mmol aniline, 0.005mmol [Ir(cod )Cl] 2 , 0.02mmol palladium trifluoroacetate, 1.0mmol silver carbonate, 0.05mmol tricyclohexylphosphine, 1.0mmol cesium hydroxide and 5ml dioxane, replace the reaction tube with nitrogen for 3 times, and then heat to 110°C, the reaction was refluxed for 12 hours. The oil bath was removed, and the water bath was lowered to room temperature; 3ml of water was added to the reaction solution, extracted three times with 5ml of dichloromethane, the organic phases were combined and washed with anhydrous MgSO 4 Dry for 30 minutes and filter; the filtrate is concentrated with a rotary evaporator, and the concentrated solid is recrystallized with dichloromethane as a solvent to obtain a pure product with a yield of 80%. The nuclear magnetic analysis data of this product are as f...

Embodiment 2

[0020] Embodiment 2: the preparation of 7-methyl-5,6-dihydrophenanthidine

[0021] Under the protection of an inert gas (such as high-purity nitrogen), add 1.0mmol o-methylbenzyl alcohol, 1.5mmol o-bromoaniline, 0.01mmol [ Ir(cod)Cl] 2 , 0.05mmol palladium acetate, 2.0mmol silver carbonate, 0.08mmol tricyclohexylphosphine, 2.0mmol potassium hydroxide and 5ml toluene, replace the reaction tube with nitrogen for 3 times, then heat to 110°C with an oil bath under magnetic stirring, and react to reflux 20 hours. The oil bath was removed, and the water bath was lowered to room temperature; 3ml of water was added to the reaction solution, extracted three times with 5ml of dichloromethane, the organic phases were combined and washed with anhydrous MgSO 4 Dry for 30 minutes and filter; the filtrate is concentrated with a rotary evaporator, and the concentrated solid is recrystallized with dichloromethane as a solvent to obtain a pure product with a yield of 88%. The nuclear magneti...

Embodiment 3

[0023] Example 3: Preparation of 9-methyl-5,6-dihydrophenanthidine

[0024] Under the protection of inert gas (such as high-purity nitrogen), add 1.0mmol p-methylbenzyl alcohol, 2.0mmol o-bromoaniline, 0.015mmol [ Ir(cod)Cl] 2 , 0.1mmol palladium chloride, 1.5mmol silver trifluoroacetate, 0.2mmol tricyclohexylphosphine, 1.5mmol cesium carbonate and 5ml benzene, replace the reaction tube with nitrogen for 3 times, then heat to 80°C with an oil bath under magnetic stirring, The reaction was refluxed for 24 hours. The oil bath was removed, and the water bath was lowered to room temperature; 3ml of water was added to the reaction solution, extracted three times with 5ml of dichloromethane, the organic phases were combined and washed with anhydrous MgSO 4 Dry for 30 minutes and filter; the filtrate is concentrated with a rotary evaporator, and the concentrated solid is recrystallized with dichloromethane as a solvent to obtain a pure product with a yield of 83%. The nuclear magn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com