Convenient and simple method for increasing high-temperature reaction preparation efficiency of complex inorganic color pigment (CICP)

A composite inorganic pigment and high-temperature reaction technology, which is applied in the direction of inorganic chemistry, chemical instruments and methods, antimony compounds, etc., can solve the problems of high sintering temperature and long time consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

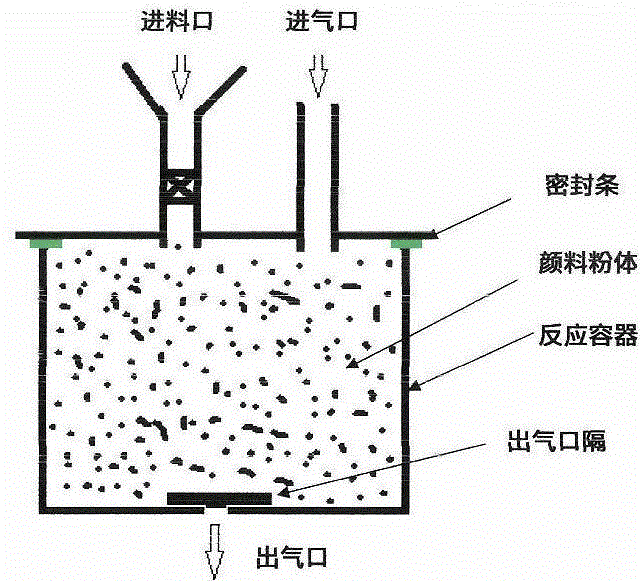

Image

Examples

Embodiment 1

[0022] Taking the stoichiometric ratio of Fe 2 o 3 and Cr 2 o 3 , After mixing evenly in the mortar, equal parts are divided into several parts, placed in the sagger, and sintered at a temperature of 1100 ° C. The sintered iron chrome black is identified after being washed with water, filtered, dried and pulverized.

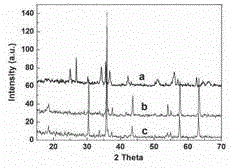

[0023] figure 2 The XRD patterns of Fechrome black with and without air pressure differential densification saggar at different reaction times are shown. Among them: a) is the XRD pattern of the iron chrome black without using pressure difference to compact the sagger, reacted at 1100°C for 8 hours; Reaction for 8 hours; c) is the XRD pattern of Fechrome black without using pressure difference to compact the sagger, reacting at 1100° C. for 15 hours.

[0024] It can be seen that after 8 hours of reaction, the FeCr black without the pressure difference densification sagger still exhibits the XRD characteristics of the reaction raw materials, while the FeCr ...

Embodiment 2

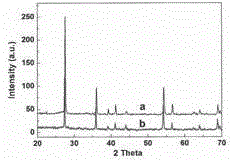

[0026] Take the stoichiometric ratio of TiO 2 、Ni 2 o 3 and Sb 2 o 3 , after mixing evenly in the mortar, the equal amount was divided into several parts, placed in the sagger, and reacted at 1100°C for 10 hours under the condition of not adopting the pressure difference compacting saggar, and under the condition of using the pressure difference compacting sagger React at 1000°C for 10 hours. The sintered nickel titanium yellow is identified after being washed with water, filtered, dried and pulverized.

[0027] image 3 Shows the comparison of the XRD spectrum of the Nitinol yellow at different temperatures with and without the pressure difference compacting sagger, wherein: a) is the XRD spectrum of the Nitinol yellow that does not adopt the pressure difference compaction sagger, 1100 ℃ for 8 hours, and b) is the XRD pattern of Nitinol yellow in a sagger compacted by air pressure difference, and reacted for 8 hours at 1050 ℃. It can be seen that Nitinol yellow samples...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com