Front-rear-surface dual-coated matte panel and manufacturing method thereof

A manufacturing method, front and back technology, applied in the direction of chemical instruments and methods, lamination, layered products, etc., can solve the problems that are not fully grasped, and achieve the effect of high scratch resistance and good corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

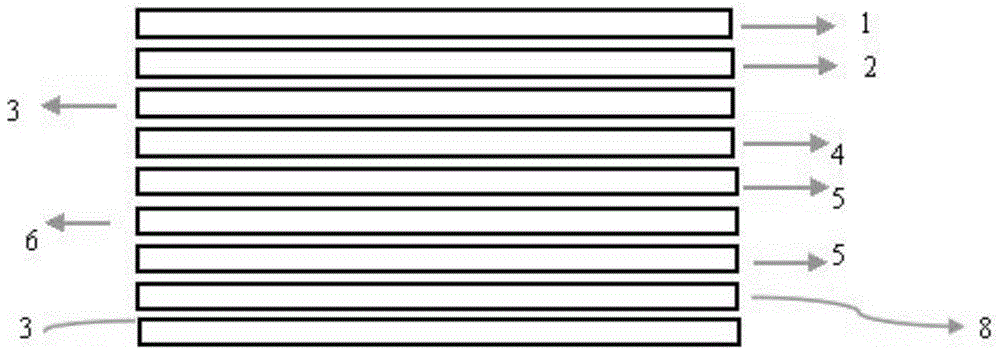

[0025] Such as figure 1 As shown, a front and back double-coated matte panel and its manufacturing method, its composite steel plate includes a PE protective film 1, a first adhesive layer 2, and a matte surface paint that are arranged in sequence from top to bottom and closely bonded to each other. Layer 3, front primer layer 4, chemical treatment layer 5, steel plate 6, back primer layer 8, the preparation method of the front and back double-coated matt panels of this embodiment includes the following steps:

[0026] Step 1, coating a polyurethane adhesive on the PE electronic film 1 to form the first adhesive layer 2, that is, to obtain a PE film with a thickness of 0.038mm;

[0027] Step 2, after the steel plate 6 is cleaned and degreased, the degreasing point is 15pt, and the chemical treatment layer is rolled on the front and back of the steel plate to form a chemical treatment layer 5 with a thickness of 2 μm;

[0028] Step 3, roll coating polyester resin on the chemic...

Embodiment 2

[0033] Such as figure 1 As shown, a front and back double-coated matte panel and its manufacturing method, its composite steel plate includes a PE protective film 1, a first adhesive layer 2, and a matte surface paint that are arranged in sequence from top to bottom and closely bonded to each other. Layer 3, front primer layer 4, chemical treatment layer 5, steel plate 6, back primer layer 8, the preparation method of the front and back double-coated matt panels of this embodiment includes the following steps:

[0034] Step 1, coating a polyurethane adhesive on the PE electronic film 1 to form the first adhesive layer 2, that is, to obtain a PE film with a thickness of 0.038mm;

[0035] Step 2, after the steel plate 6 is cleaned and degreased, the degreasing point is 15pt, and the chemical treatment layer is rolled on the front and back of the steel plate to form a chemical treatment layer 5 with a thickness of 2 μm;

[0036] Step 3, roll coating polyester resin on the chemic...

Embodiment 3

[0041] Such as figure 1 As shown, a front and back double-coated matte panel and its manufacturing method, its composite steel plate includes a PE protective film 1, a first adhesive layer 2, and a matte surface paint that are arranged in sequence from top to bottom and closely bonded to each other. Layer 3, front primer layer 4, chemical treatment layer 5, steel plate 6, back primer layer 8, the preparation method of the front and back double-coated matt panels of this embodiment includes the following steps:

[0042] Step 1, coating a polyurethane adhesive on the PE electronic film 1 to form the first adhesive layer 2, that is, to obtain a PE film with a thickness of 0.04mm;

[0043] Step 2: After the steel plate 6 is cleaned and degreased, the degreasing point is 20pt, and the chemical treatment layer is rolled on the front and back of the steel plate to form a chemical treatment layer 5 with a thickness of 3 μm;

[0044] Step 3, roll-coat polyester resin on the chemical t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com