Nano palladium supported amphipathic carbon sphere catalyst and application thereof to aqueous-phase Heck reaction

A catalyst and amphiphilic technology, which is used in the field of amphiphilic carbon spheres catalyzing water-phase Heck reaction, can solve the problems of difficult contact between reaction substrates and catalysts, reducing the contact area between non-polar surfaces and water, and difficult for water to contact each other. , to achieve the effect of increased contact area, convenient recycling and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example 1

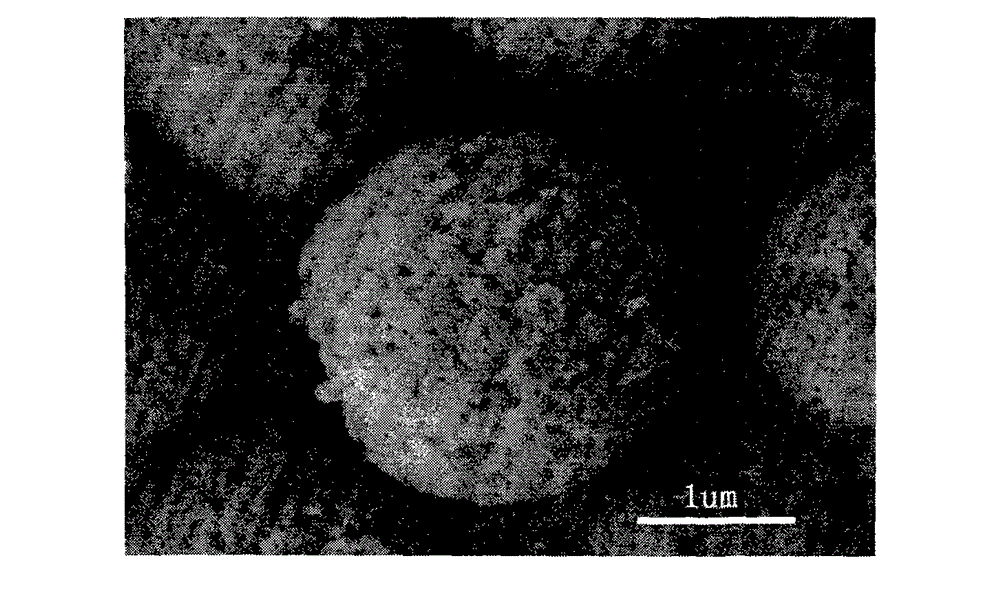

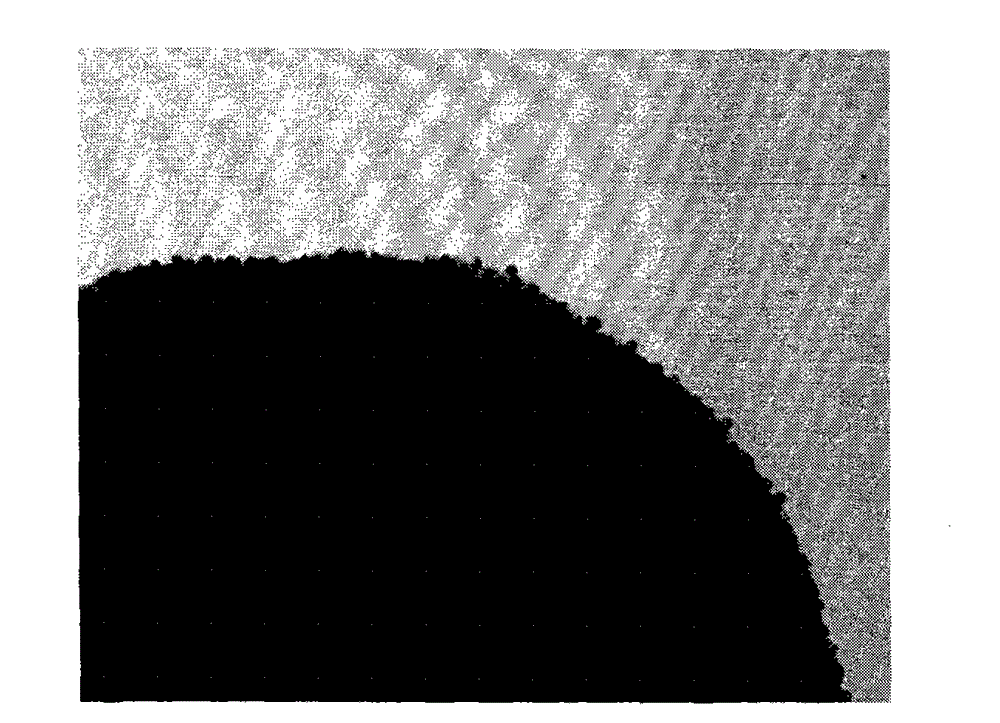

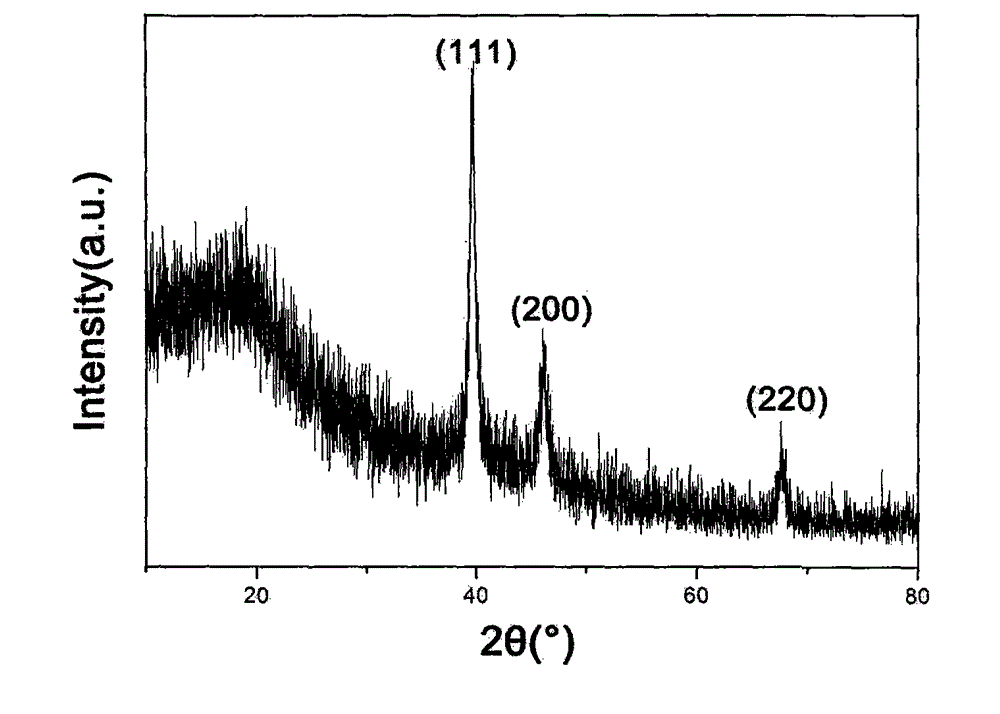

[0023] Preparation of Pd / PHCSs catalyst: In a 50ml round bottom flask, 300mg PHCSs, 30mg PdCl 2 Dissolve in 30ml ethanol, heat and stir at reflux for 2h. After the reaction was completed, cool to room temperature, centrifuge, and pour out the ethanol solvent to obtain a gray-black solid. Then, it was centrifugally washed with water (15ml×2) and ethanol (15ml×3), and vacuum-dried at 45° C. for 12 hours to obtain a Pd / PHCSs catalyst. ICP-OES measured that the content of Pd in the catalyst was 4.01wt%.

Embodiment example 2

[0025] Take 1 mmol of iodobenzene and 2 mmol of acrylic acid and add it to 5 ml of deionized water, and add k 2 CO 3 2mmol, Pd / PHCSs catalyst 20mg. The reaction was stirred under reflux for 4h. After the reaction was completed, it was cooled to room temperature, and the product was extracted with diethyl ether (3×10 ml). Both the catalyst and the product are soluble in water under alkaline conditions. Add dilute hydrochloric acid to adjust the pH to acidity, and the product cinnamic acid will be transferred from the water phase to the oil phase, and then separated with a separatory funnel. Anhydrous Na for organic phase 2 SO 4 Dry for 2h. Finally, the organic phase was separated by column chromatography to obtain cinnamic acid with a calculated yield of 91%.

Embodiment example 3

[0027] Take 1 mmol of p-methyl iodobenzene and 2 mmol of acrylic acid into 5 ml of deionized water, and add k 2 CO 3 2mmol, Pd / PHCSs catalyst 20mg. The reaction was stirred under reflux for 4h. After the reaction was completed, it was cooled to room temperature, and the product was extracted with diethyl ether (3×10 ml). Dilute hydrochloric acid was added to adjust the pH to acidity, and the product was transferred from the water phase to the oil phase, and then separated with a separatory funnel. Anhydrous Na for organic phase 2 SO 4 Dry for 2h. Finally, the organic phase was separated by column chromatography to obtain 4-methylcinnamic acid, and the calculated yield was 90%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com