High-temperature steam sterilization equipment

A technology of disinfection equipment and high-temperature steam, applied in heating, irradiation and other directions, can solve the problems of energy waste, water content, affecting product quality, etc., to save energy, reduce disinfection costs, and save water.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] Preferred embodiments of the present invention are described below, and it should be understood that the preferred embodiments described here are only used to illustrate and explain the present invention, and are not intended to limit the present invention.

[0013] To achieve the above object, the present invention provides the following technical solutions:

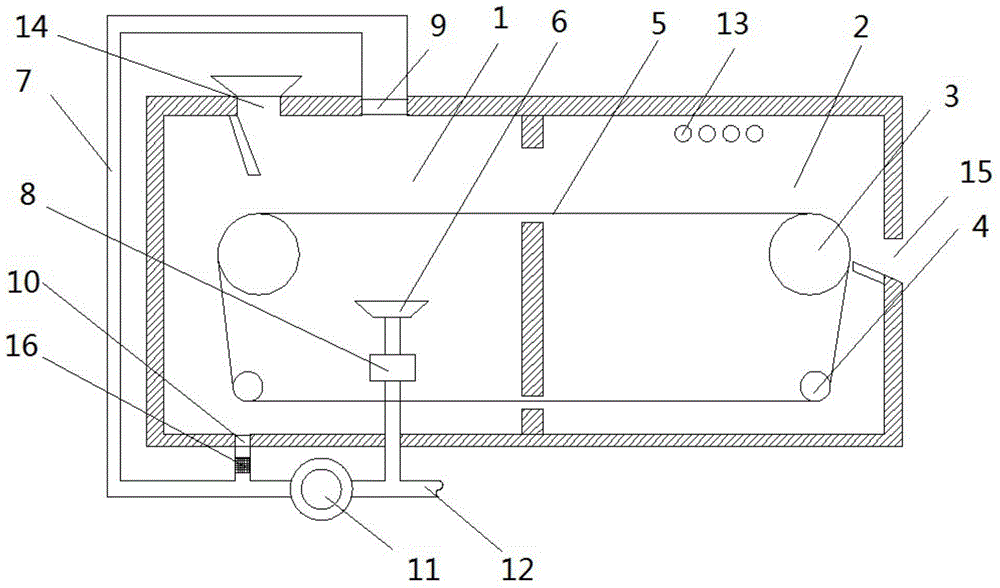

[0014] As shown in the figure: a high-temperature steam disinfection equipment, including a disinfection box 1, a drying box 2 and a transmission mechanism, the disinfection box 1 and the drying box 2 are communicated through a transmission mechanism; the transmission mechanism includes two transmission Wheel 3, two guide wheels 4 and conveyor belt 5, the guide wheel 4 guides the conveyor belt 5 downwards, so that there is enough space between the upper and lower conveyor belts to set the steam nozzle 6, and the steam nozzle 6 is located in the disinfection box 1, the steam nozzle 6 is connected to the steam gene...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com