Multi-layered shrink films

A technology of shrink film and surface layer, applied in the direction of layered products, synthetic resin layered products, transportation and packaging, etc., can solve the problems of limited reduction, low modulus, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] The following examples illustrate the invention but are not intended to limit the scope of the invention.

[0051] Preparation of Ethylene-Based Polymer Compositions Used in the Examples of the Invention

[0052] Examples (Inv. Comp. Ex.) 1-3 of the inventive composition are ethylene-based polymer compositions prepared in a series of two-solution polymerization reactors under the conditions shown in Tables 1-3. Table 4 summarizes the catalysts and catalyst components referred to in Table 3. Example 4 of the inventive composition is an ethylene-based polymer composition prepared under similar conditions in a series of two solution polymerization reactors.

[0053] Table 1

[0054]

[0055]

[0056] Table 2

[0057]

[0058]

[0059] table 3

[0060]

[0061]

[0062] Table 4

[0063]

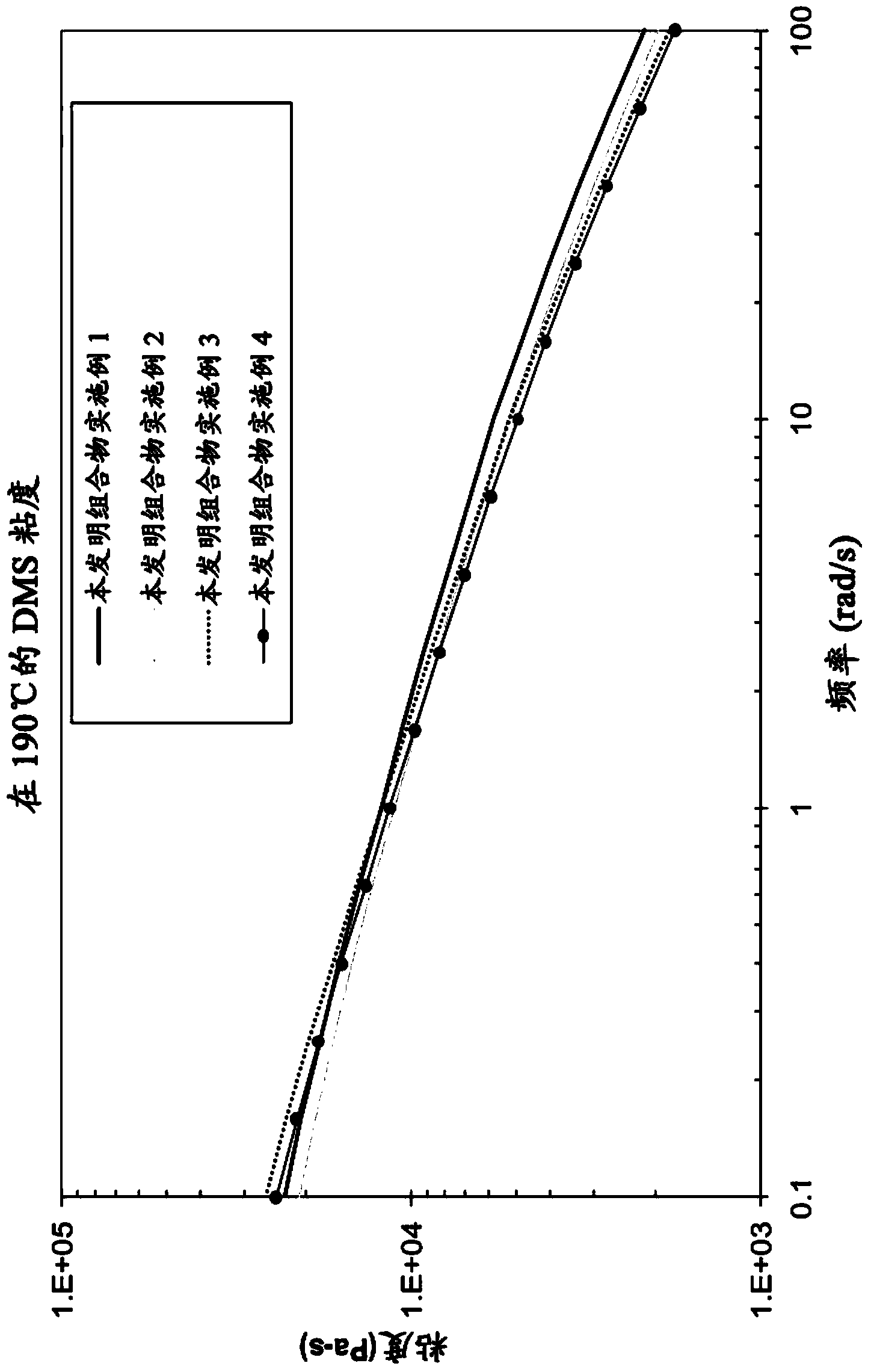

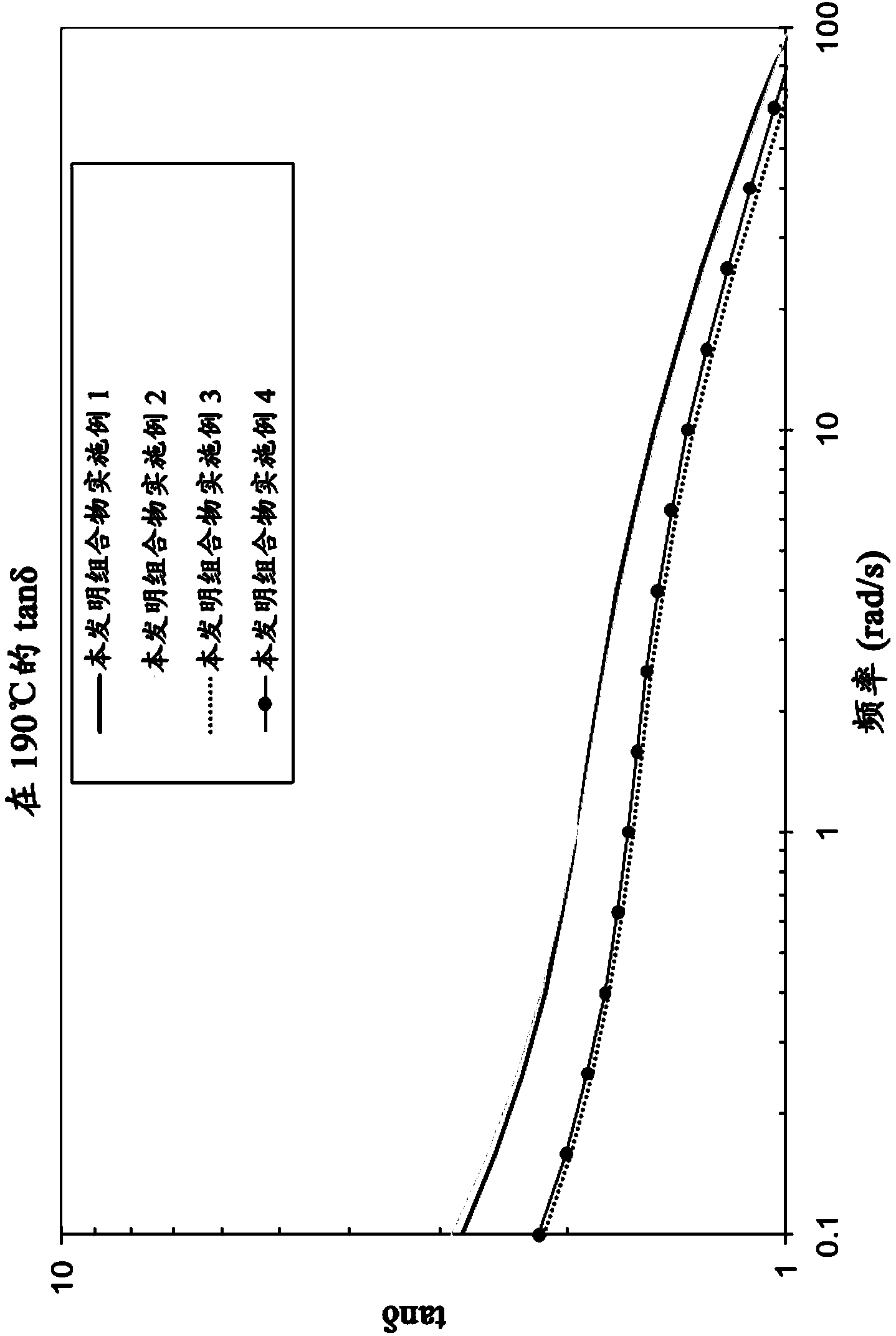

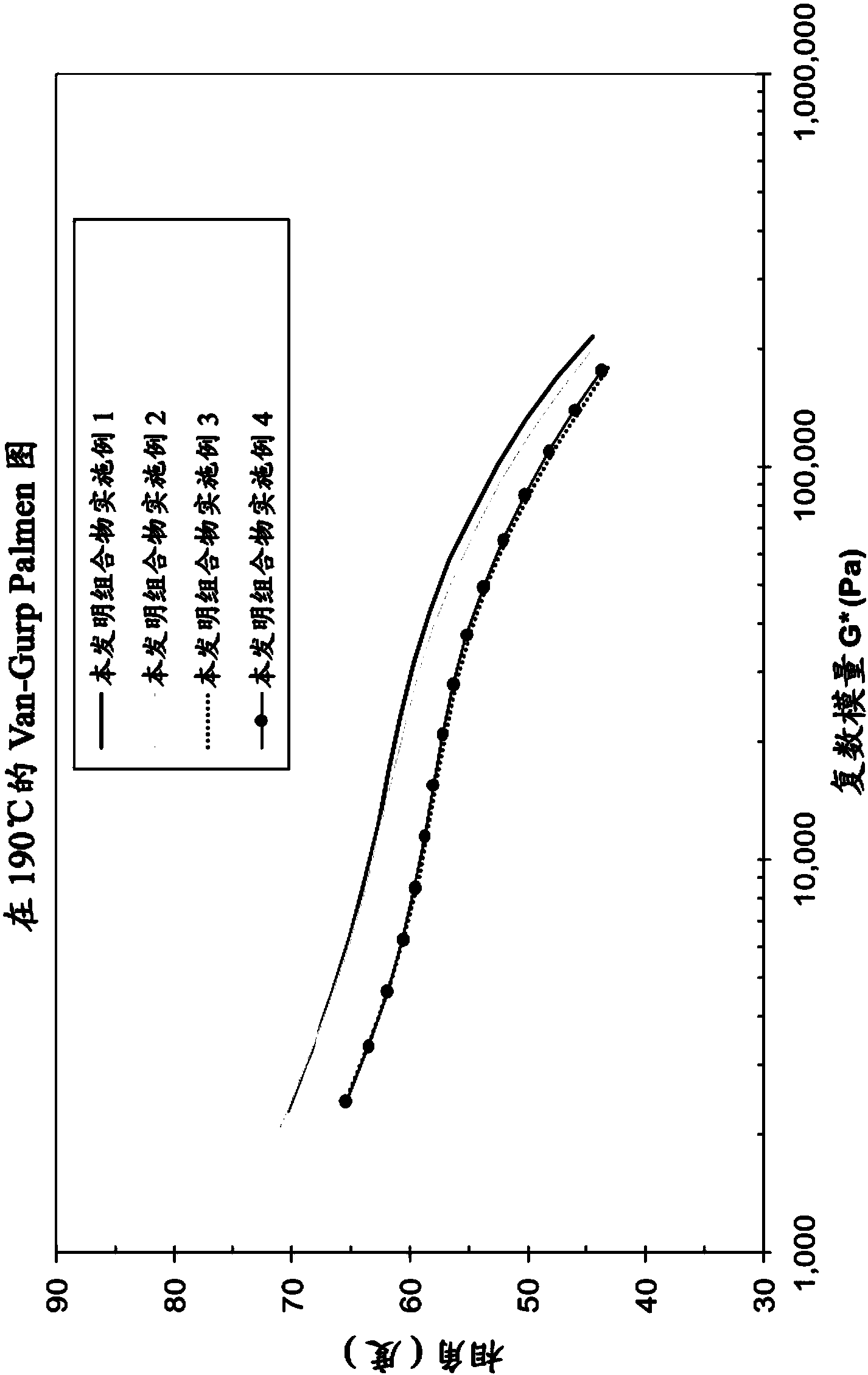

[0064] Various properties of Examples 1-4 of the compositions of the present invention are shown in Tables 5-14.

[0065] table 5

[0066]

[0067] Table 6 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com