Method for synthesizing LiFePO4/C positive material of lithium ion battery

A technology for lithium-ion batteries and positive electrode materials, applied in battery electrodes, secondary batteries, circuits, etc., can solve the problems of no longer obvious advantages in synthesis, and achieve the effect of simplifying the experimental process, easy control of conditions, and convenient industrialized large-scale production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

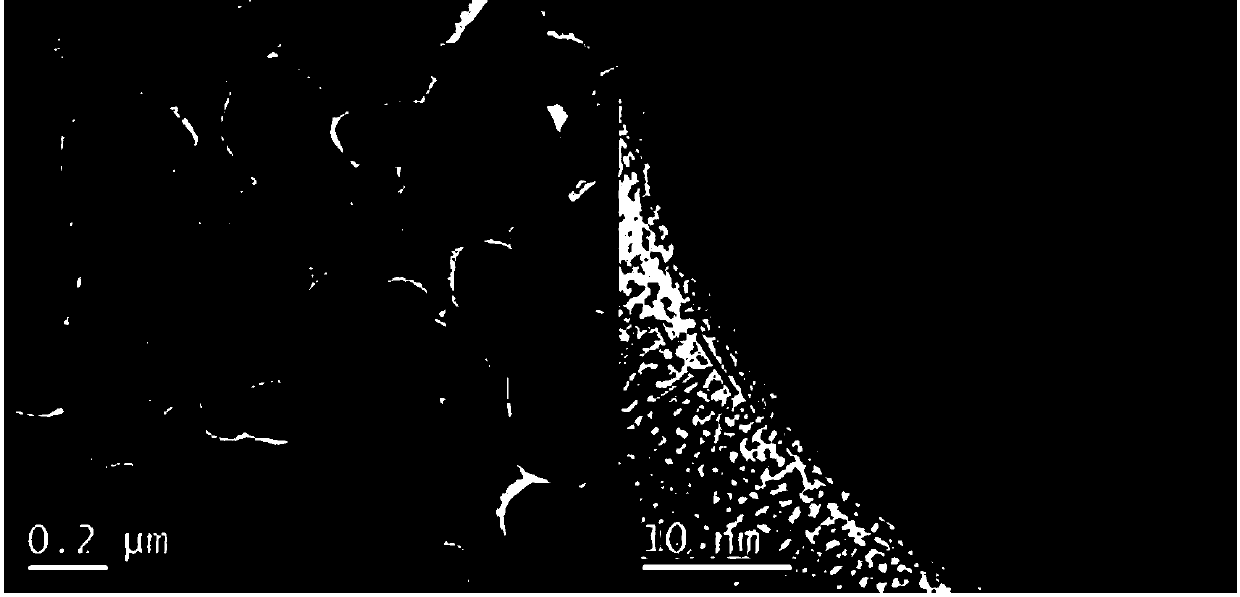

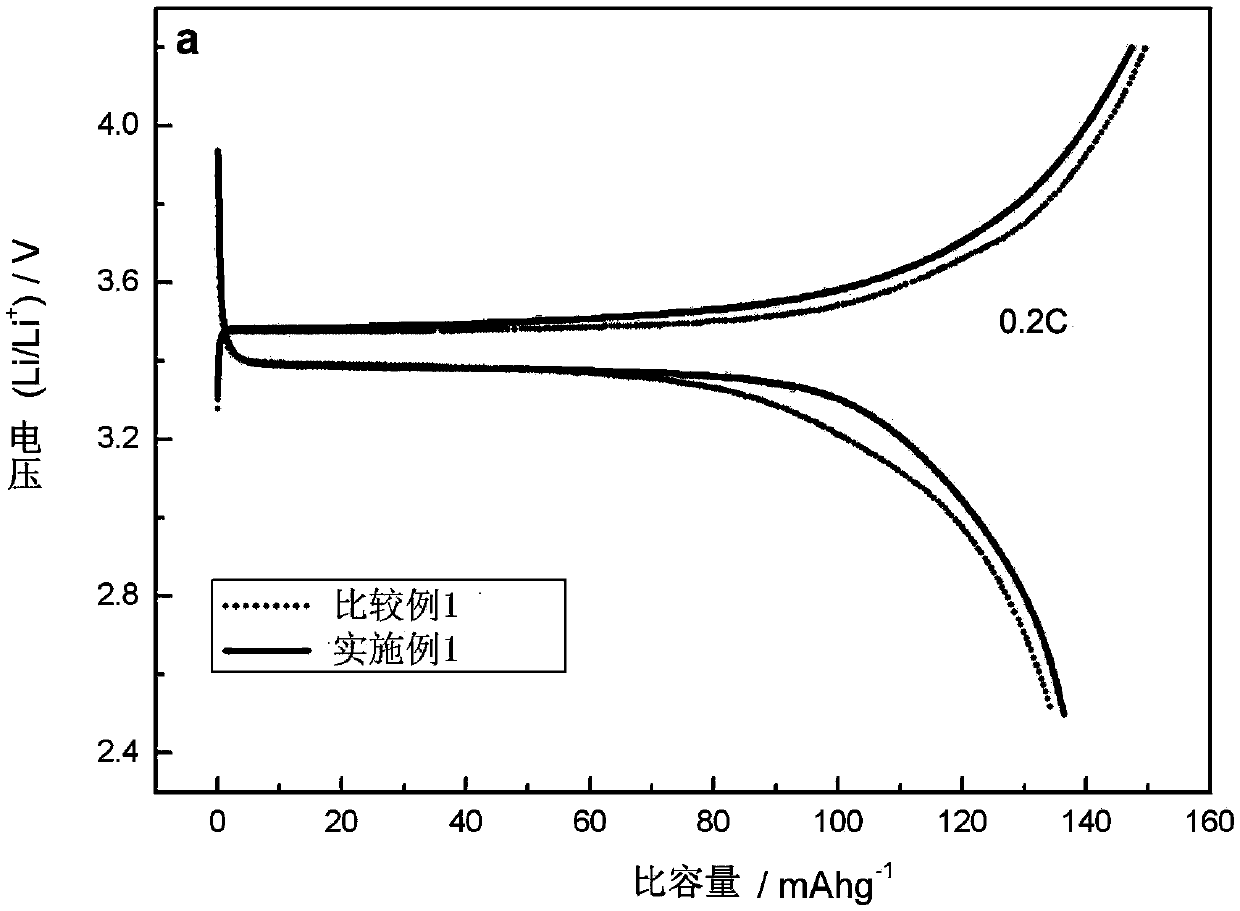

Embodiment 1

[0031] Weigh LiOH·H at a molar ratio of 3:1 2 O and H 3 PO 4 Each was dissolved in distilled water to form 3 mol / L and 1 mol / L solutions for use; first, 0.5 ml of aniline was added to the phosphoric acid solution; secondly, the completely dissolved lithium hydroxide solution was added to the above mixture , instantly generating white Li 3 PO 4 precipitation; again, FeSO containing a small amount of ascorbic acid 4 ·7H 2 O solution (with H 3 PO 4 same number of moles) was dropped into the above system; after stirring for 5 min, it was transferred to the reaction kettle, N 2 After bubbling for 10 min, put it directly into a blast drying oven at 180 °C for 2 h, take out the reaction kettle and cool it down to room temperature, wash the precipitate obtained by centrifugation with distilled water several times, then wash it twice with absolute ethanol, and then put it in 60 °C oven, after drying, LiFePO 4 / PANI powder, LiFePO 4 / PANI powder was placed in a tube furnace at...

Embodiment 2

[0036] Weigh LiOH·H at a molar ratio of 3:1 2 O and H 3 PO 4 Each was dissolved in distilled water to form 3 mol / L and 1 mol / L solutions for use; first, 0.5 ml of aniline was added to the phosphoric acid solution; secondly, the completely dissolved lithium hydroxide solution was added to the above mixture , instantly generating white Li 3 PO 4 precipitation; again, FeCl containing a small amount of ascorbic acid 2 4H 2 O solution (with H 3 PO 4 same number of moles) was dropped into the above system; after stirring for 5 min, it was transferred to the reaction kettle, N 2 Bubbling for 10 min, then directly put it into a blast drying oven at 180 °C for 2 h, take out the reaction kettle and cool it down to room temperature, wash the precipitate obtained by centrifugation with distilled water several times, then put it in a 60 °C oven, and dry it to obtain LiFePO 4 / PANI powder, LiFePO 4 / PANI powder was placed in a tube furnace at 500 °C under N 2 Sintered under the at...

Embodiment 3

[0038] Weigh LiOH·H at a molar ratio of 3:1 2 O and H 3 PO 4 Each was dissolved in distilled water to form 3 mol / L and 1 mol / L solutions for use; first, 1ml of aniline was added to the phosphoric acid solution; secondly, the completely dissolved lithium hydroxide solution was added to the above mixed solution, Instantly generates white Li 3 PO 4 precipitation; again, FeSO containing a small amount of ascorbic acid 4 ·7H 2 O solution (with H 3 PO 4 The same number of moles) was dropped into the above system. After stirring for 5 min, transfer to the reaction kettle, N 2 Bubbling for 10 min, then directly put it into a blast drying oven at 180 °C for 2 h, take out the reaction kettle and cool it down to room temperature, wash the precipitate obtained by centrifugation with distilled water several times, then put it in a 60 °C oven, and dry it to obtain LiFePO 4 / PANI powder, LiFePO 4 / PANI powder was placed in a tube furnace at 600 °C under N 2 Sintered under the atmo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com