Coating method of border glue and substrate mother board

A coating method and border glue technology, applied in the direction of instruments, nonlinear optics, optics, etc., can solve the problems of poor cutting, uneven box thickness, inconvenient coating, etc., to reduce the mura problem, uniform box thickness, reduce effect of time spent

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

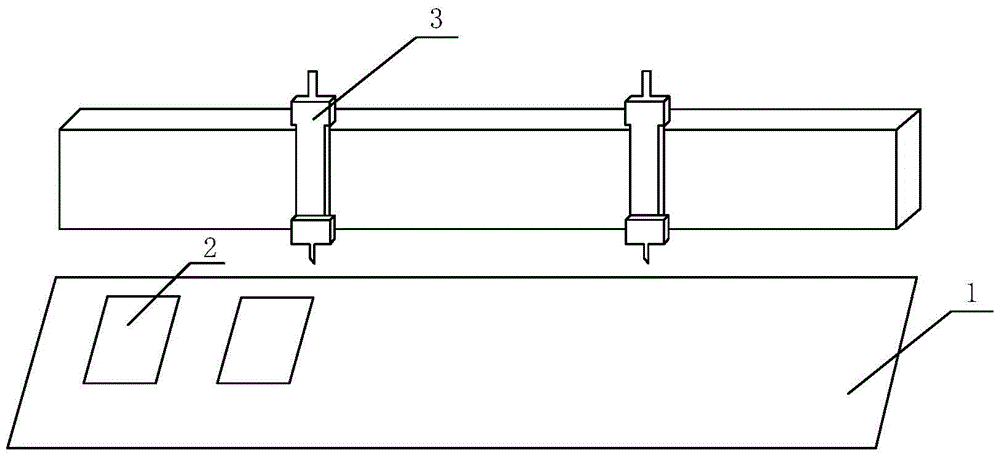

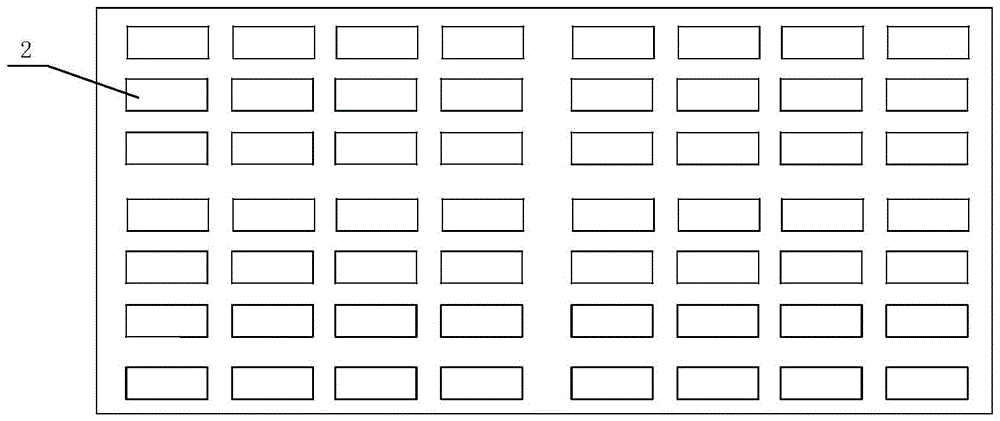

[0046] Embodiment 2 of the present invention provides a substrate mother board, refer to Figure 10 , the substrate motherboard includes: several first substrates, the coating equipment adopts a one-stroke continuous coating method to coat the frame glue on the multiple first substrates, and the coating equipment moves from a corner of the first substrate to the adjacent first substrate The coating line at one corner of is a broken line.

[0047] When the coating equipment moves from a corner of the first substrate to a corner of the adjacent first substrate, the coating line of the coating equipment is a broken line, and therefore, the shape of the sealant in the corresponding area is a broken line. And at this time, the position of the intersection point of the sealant on the main board of the substrate is at the corner of the first substrate, thereby effectively reducing the mura problem caused by the uneven thickness of the box.

[0048] In this embodiment, optionally, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com