Powerful and mechanical automatic-locking hydraulic cylinder

A powerful machine and hydraulic cylinder technology, applied in the field of hydraulic cylinders, can solve the problems that the accuracy and reliability cannot be guaranteed, the oil circuit hydraulic cylinder is easy to leak and repair, and the accuracy cannot meet the requirements. Simple and efficient inflatable, less difficult to process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be described in detail below with reference to the accompanying drawings and examples.

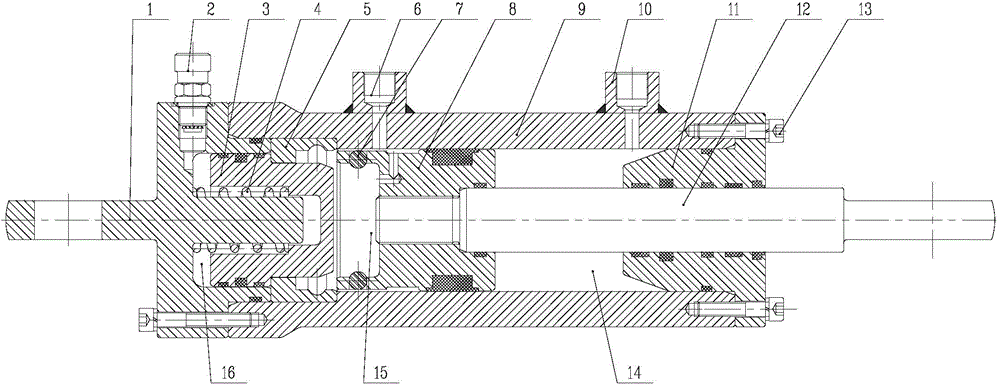

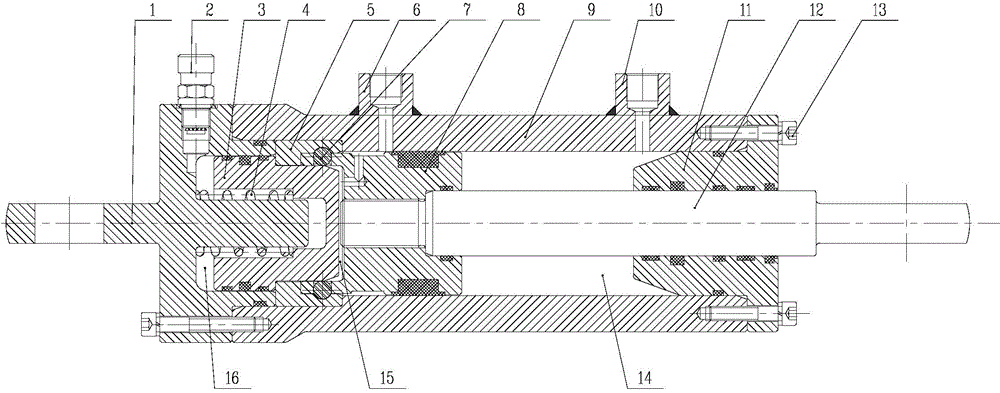

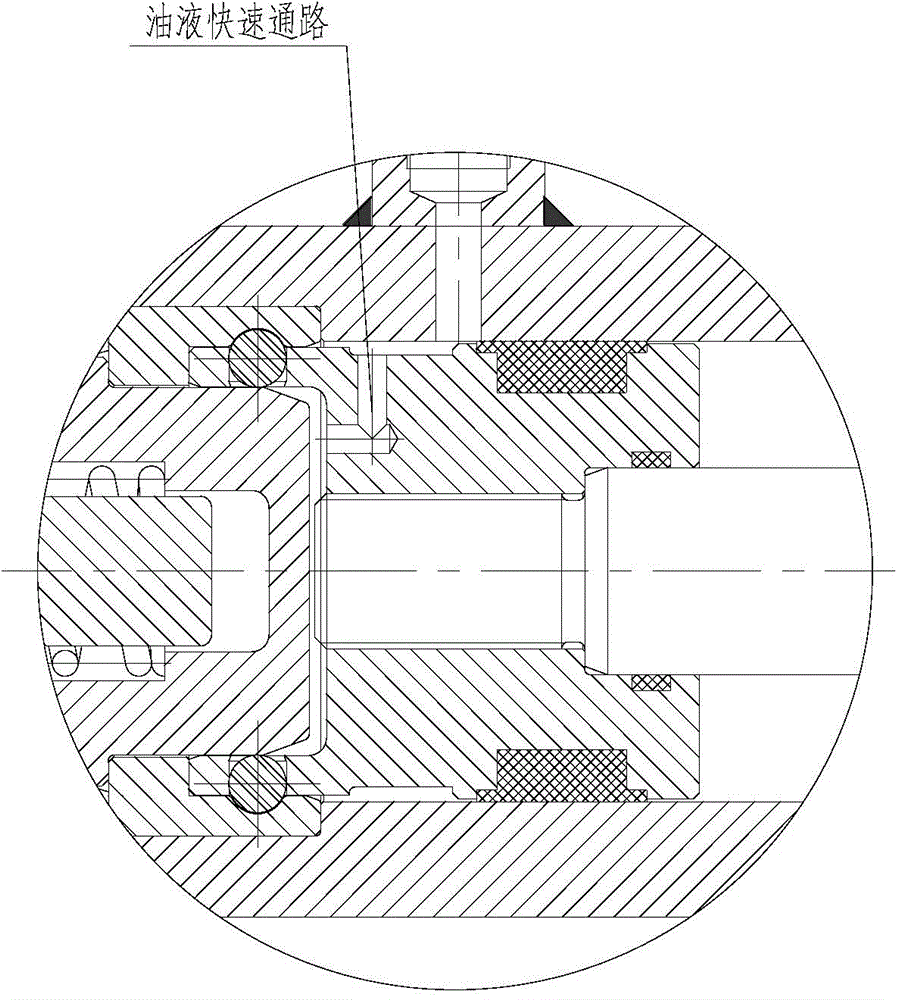

[0029] as attached figure 1 As shown, the present invention provides a powerful mechanical self-locking hydraulic cylinder, including a cylinder head 1, an air charging valve 2, a brake block 3, a spring 4, a locking block 5, a steel ball 7, a piston 8, a cylinder barrel 9, and a cylinder bottom 11 , piston rod 12 and screw 13;

[0030] Wherein, one end of the cylinder head 1 is provided with a coaxial annular groove and a guide column, and the outer peripheral surface of the cylinder head 1 is provided with an inflation valve 2 communicating with the annular groove;

[0031] The central hole on the brake block 3 is a step blind hole, the small diameter section of the step blind hole is in clearance fit with the guide column of the cylinder head 1, and the spring 4 is formed between the large diameter section of the step blind hole and the guide column of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com