Ocean waste facility sludge discharging device

A technology for a sludge discharge device and facility, which is applied in the field of marine abandoned facility dismantling devices, can solve the problems of small sludge discharge, difficulty, increased maintenance and dismantling of marine abandoned facilities, etc., so as to increase the diameter of the sludge discharge pipeline and increase the sludge content. , Improve the effect of air supply

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention is described in more detail below in conjunction with accompanying drawing example:

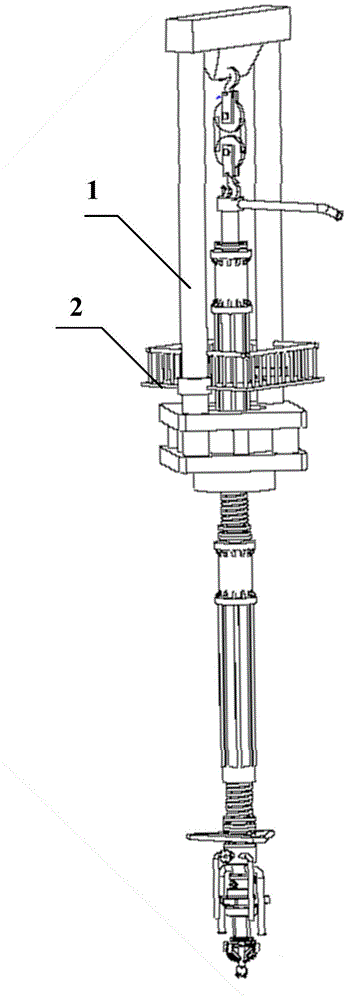

[0032] combine Figure 1-20 , The steel pile suction and discharge device for marine waste facilities combines the characteristics of the internal sludge discharge of the jacket legs, and uses a hydraulic drill bit and a high-pressure water spraying system to fully mix the sediment and the liquid for sludge discharge into a solid-liquid two-phase flow, and then pass through the air The lifting mud discharge device sucks and discharges the solid-liquid two-phase flow containing sediment to the outside of the steel pile, thereby realizing the discharge of mud inside the steel pile.

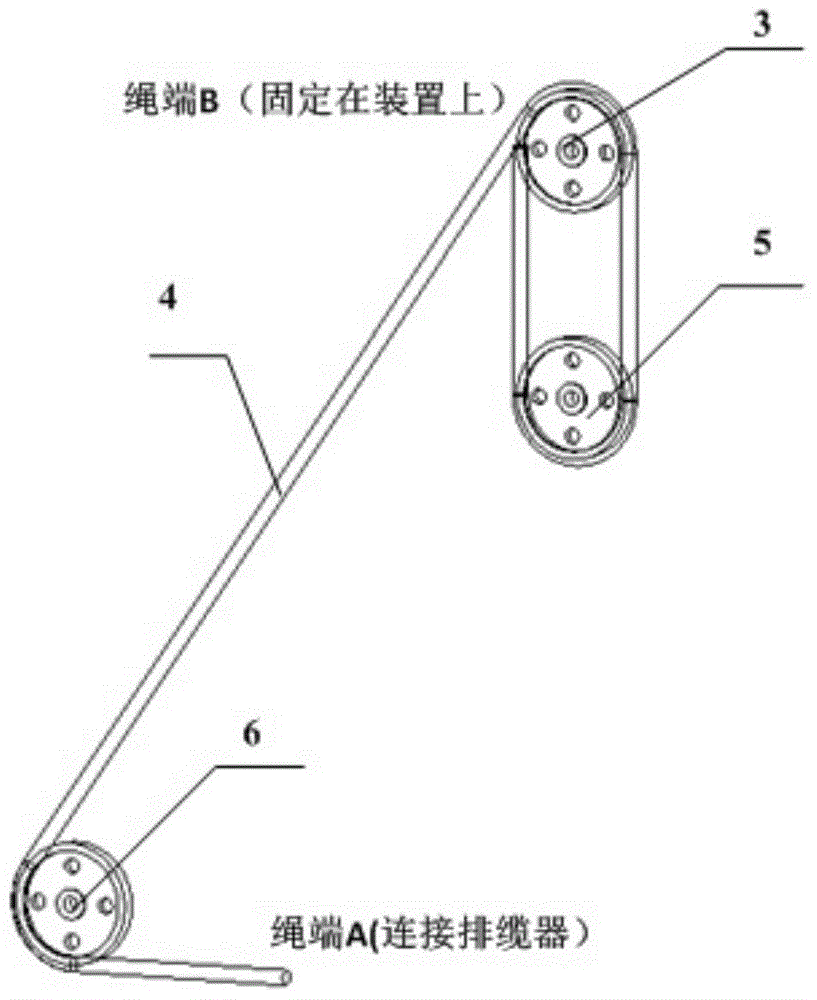

[0033] The mud discharge device of the marine waste facility is composed of four parts, the lifting device, the fixed support frame 1, the working platform 2 and the internal mud discharge system of the digging type steel pile. The lifting device is composed of a lifting cable 4, a fix...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com