Flexible compound waterproof and leakage-plugging emulsion used for wall surface and roof

A waterproof emulsion and composite technology, which is applied in the field of waterproof plugging products, flexible and composite waterproof plugging emulsion for walls and roofs, can solve the problems that have not been seen, and achieve good product adhesion, good waterproofness, and high cost-effectiveness. The effect of a reasonable distribution ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

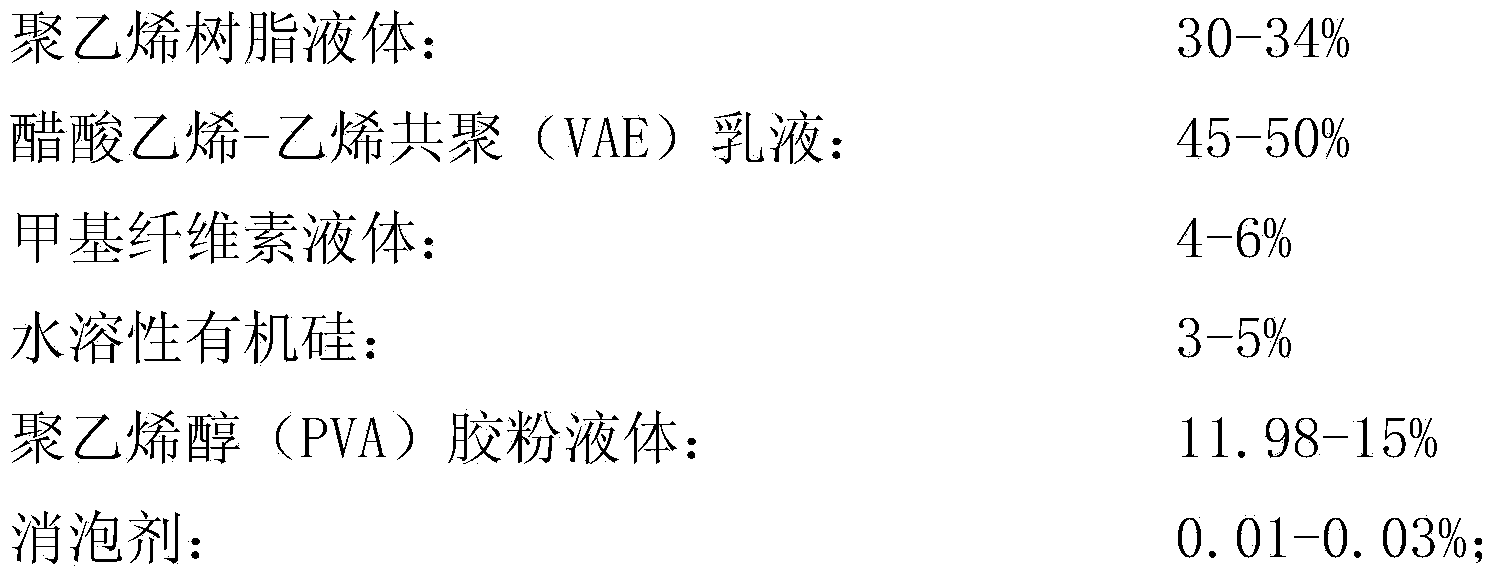

[0014] The waterproof plugging emulsion involved in this embodiment includes two components: a composite bonding waterproof emulsion and a dry powder composite sand material with a weight ratio of 1:1, and the weight percentage of each component in the composite bonding waterproof emulsion is:

[0015]

[0016] The weight percent of each composition in the described dry powder composite sand material is:

[0017]

[0018]

[0019] The preparation method of the waterproof plugging emulsion involved in this embodiment specifically includes the following process steps:

[0020] (1) Proportioning composite bonding waterproof emulsion: heat the reaction kettle at 40-50°C, add polyethylene resin liquid and polyvinyl alcohol (PVA) rubber powder liquid, and then heat up to 80-90°C until the polyethylene resin and After the polyvinyl alcohol is completely melted, add the vinyl acetate-ethylene copolymer (VAE) emulsion of model EP707K, methyl cellulose liquid and water-soluble ...

Embodiment 2

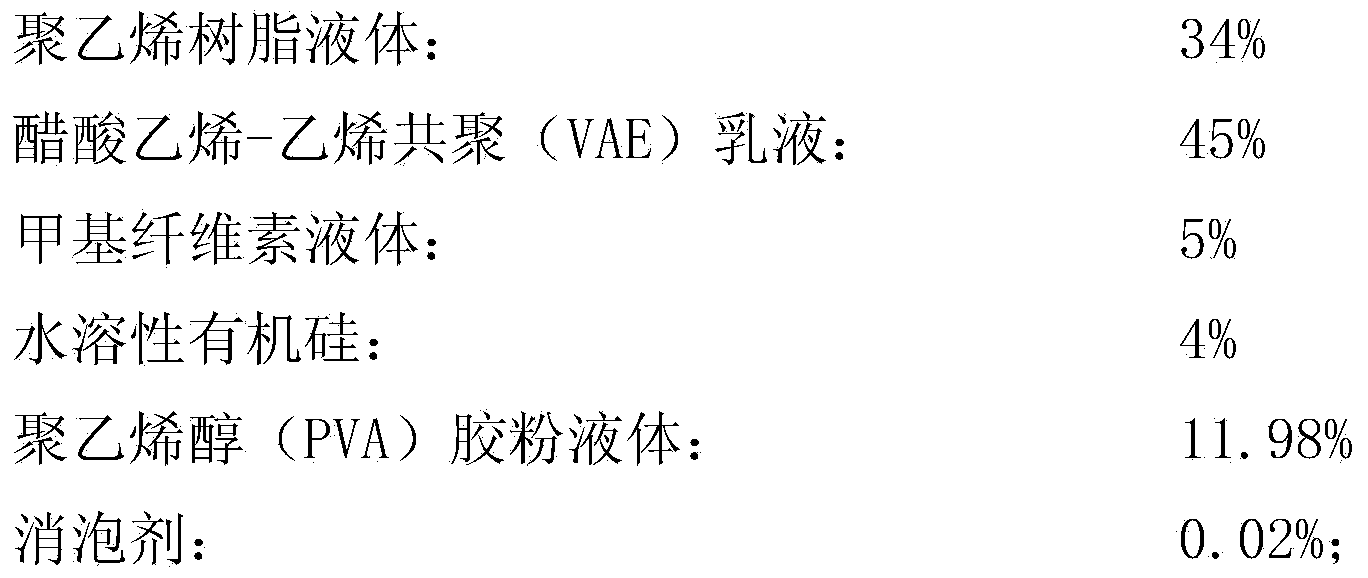

[0025] The waterproof plugging emulsion involved in this embodiment includes two components: a composite bonding waterproof emulsion and a dry powder composite sand material with a weight ratio of 1:1, and the weight percentage of each component in the composite bonding waterproof emulsion is:

[0026]

[0027] The weight percent of each composition in the described dry powder composite sand material is:

[0028]

[0029] The preparation method of this embodiment is the same as that of Example 1, and each index all meets the requirements of the invention.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com