Preparation method of regenerated rubber powder

A technology for reclaimed rubber and rubber powder, applied in chemical instruments and methods, filter screens, grids, etc., can solve the problems of large equipment wear, large iron content, affecting the quality of reclaimed rubber, etc., and achieve high efficiency and low wear. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] A preparation method of regenerated rubber powder, comprising the steps of separating waste tires into rings, cutting into strips, cutting into pieces, and then pulverizing and magnetically separating. The size of the rubber is about 40mm*40mm.

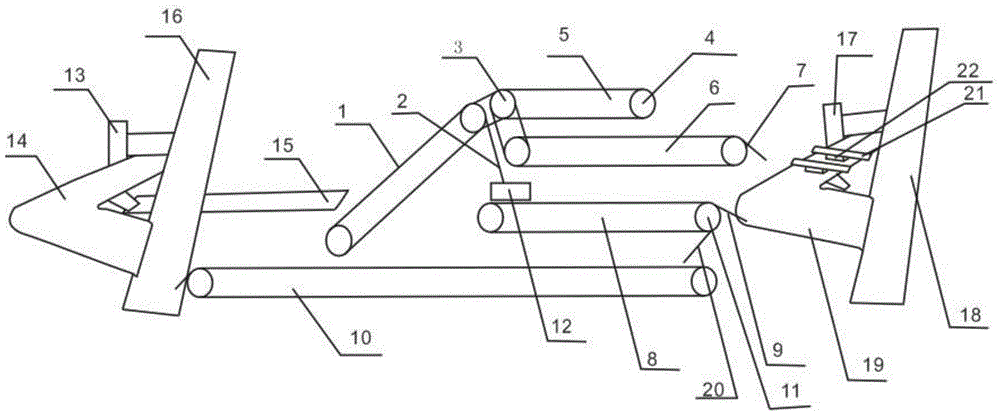

[0026] The equipment used for crushing and magnetic separation consists of a mixed material conveyor belt 1, a rubber particle hopper 2, the first full magnetic drum 3, a driven drum 4, a steel wire separation conveyor belt 5, a steel wire recovery conveyor belt 6, a steel wire hopper 7, and rubber particles. Conveyor belt 8, rubber discharge hopper 9, circulating conveyor belt 10, second full magnetic drum 11, baffle plate 12, rubber coarse crushing machine 13, first, vibrating screen 14, first conveyor belt 15, recycling conveyor belt 16, The rubber powder pulverizer 17, the second conveyor belt 18, the second vibrating screen 19, the iron-containing rubber particle receiving hopper 20, the beam 21, the iron powder collection...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com