Reel product slitting machine tool holder

A technology of slitting knife and slitting machine, which is applied in metal processing and other directions, can solve the problems of difficult surface hardness treatment of parts and high manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

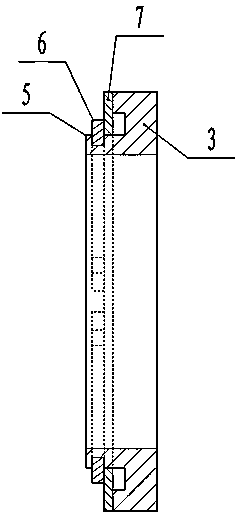

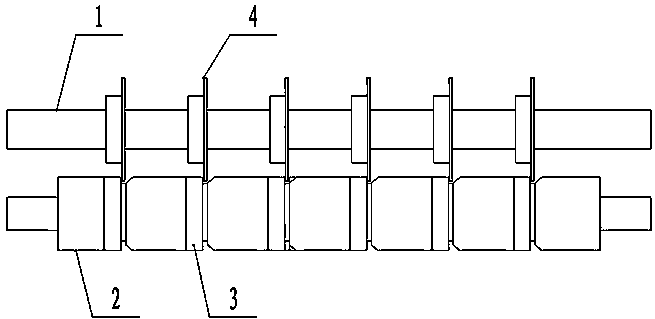

[0007] Embodiment one: if figure 1 As shown, a reel product slitting machine knife seat is installed with a slitting knife roller 1 on the frame at the front end of the winding unit of the printing production line, and a circular ring is installed on the slitting knife roller 1. The slitting knife 4 is equipped with a backing roller 2 below the slitting knife roller 1, and an annular slitting knife holder 3 is installed on the backing roller 2, and the outer peripheral edge of the slitting knife holder 3 and the slitting The outer circumference edge of knife 4 is close together, on one side of the ring-shaped slitting knife seat 3, a protruding inner ring 5 is processed, and a piece of annular blade 7 is set on the inner ring 5, Annular blade 7 is identical with the outer circumference diameter of slitting knife holder 3, on the inner ring 5 that is close to annular blade 7 outsides, is processed with draw-in groove, and snap ring 6 is installed in draw-in groove.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com