Guiding and clamping device

A technology of clamping device and guide rod, applied in positioning device, clamping, supporting and other directions, can solve the problems of unstable clamping operation and easy damage to the surface of the workpiece, and achieve the effect of stable movement, protection of the workpiece and reduction of impact.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0008] The present invention will be further described in detail below in conjunction with the drawings and specific embodiments:

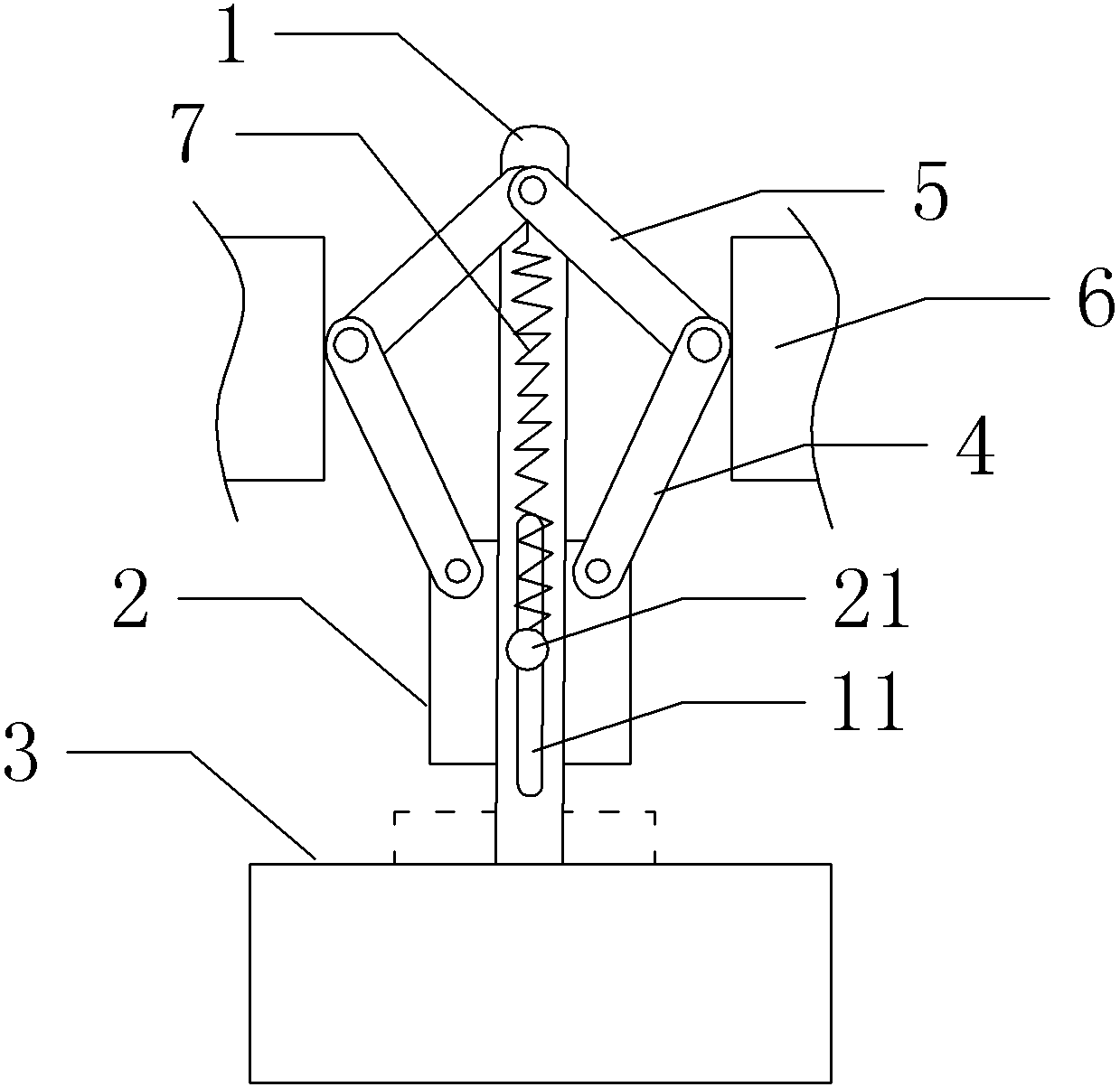

[0009] Such as figure 1 The guide clamping device shown includes a guide rod 1. The guide rod 1 is provided with a long guide groove 11 along the length of the guide rod. A pressure block 2 is provided on the side of the guide rod 1, and a pressure block 2 is provided below the pressure block 2. There is a clamping table 3, a guide pin 21 is provided in the middle of the pressure block 2, and the guide pin 21 is placed in the guide groove 11 and can slide along the guide groove 11. The upper ends of the pressure block 2 are respectively hinged with first driving rods 4, two first The ends of the driving rods are hinged to the second driving rod 5, the ends of the two second driving rods are both hinged to the top of the guide rod 1, and the hinge points of the two first driving rods and the second driving rods are provided with push blocks 6 , The p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com