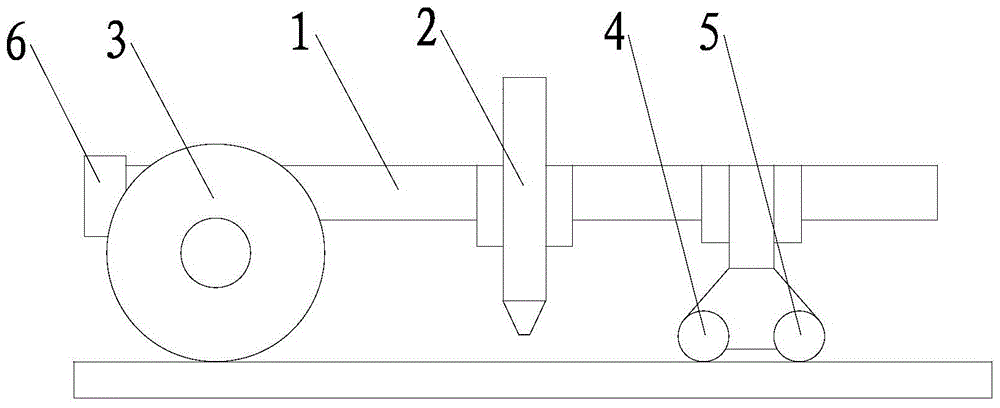

An aluminum alloy thin plate welding equipment

A thin plate welding and welding equipment technology, applied in the field of aluminum alloy welding, can solve the problems of increasing equipment cost, clamping man-hours, reducing production efficiency, and huge equipment, and achieves the effects of improving the scope of use, preventing thermal cracks, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

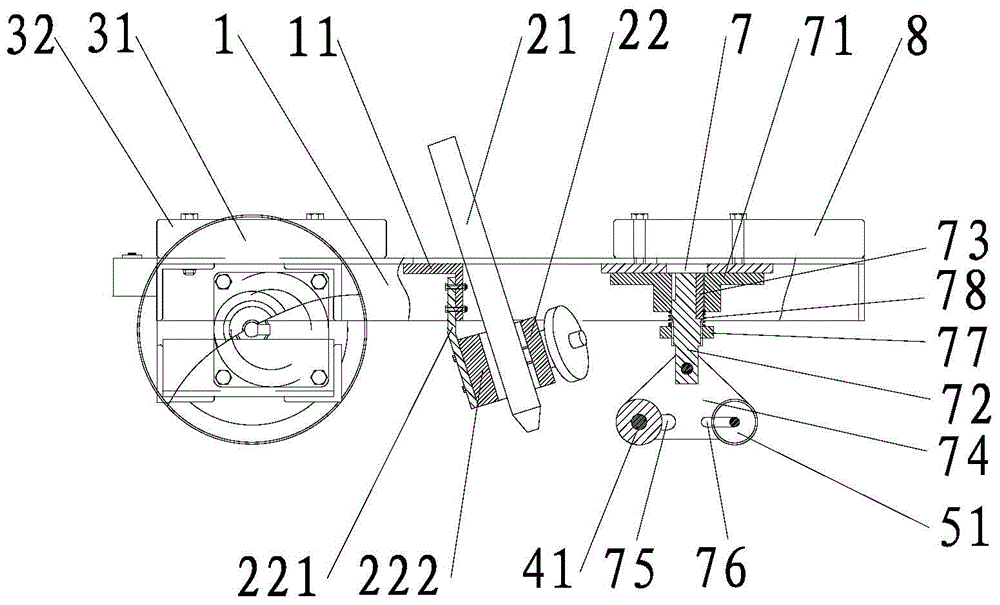

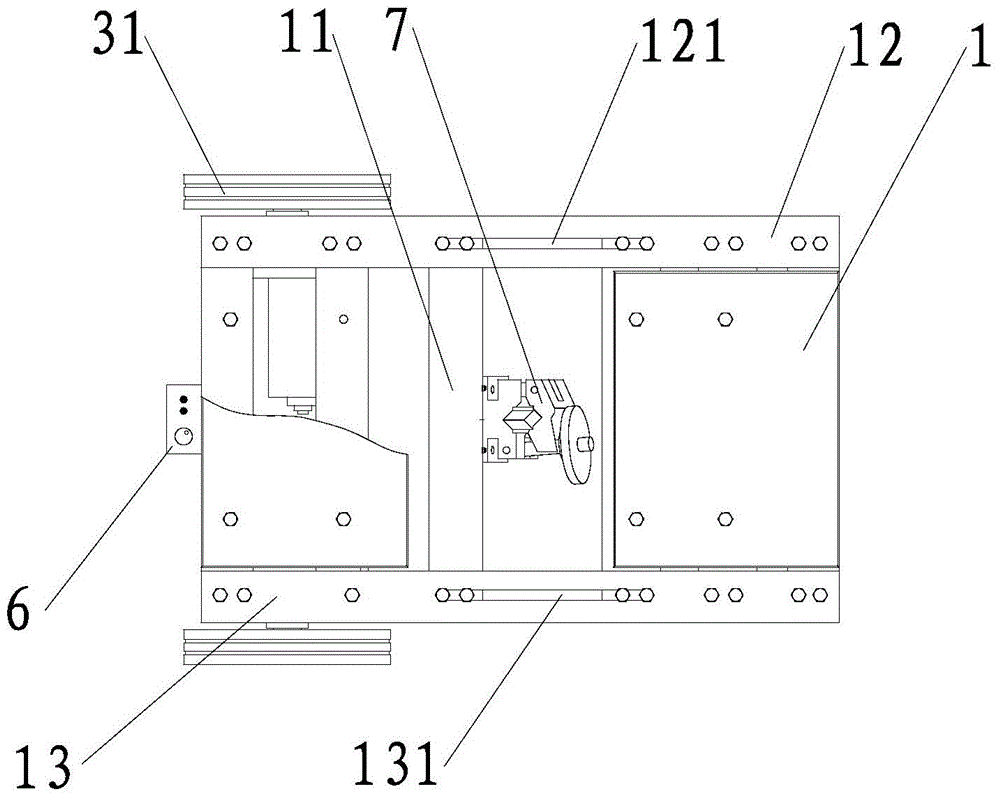

[0047] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0048] The aluminum alloy sheet welding method of the present invention comprises the following steps:

[0049] S1: Check the welding equipment before welding, clean the debris in the welding position of the workpiece to be welded, place the welding torch above the welding position, adjust the height between the welding torch and the workpiece to be welded, and make the tip of the tungsten electrode on the welding torch and the workpiece to be welded The distance between the welding workpieces is between 2mm-3mm. It should be noted that the distance between the tip of the tungsten electrode on the welding torch and the workpiece to be welded can be set according to actual needs, and it is not necessarily the distance in this embodiment. Between 2mm-3mm, if it is found that the tungsten electrode is easy to stick to the workpiece during welding,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com