Three-dimensional oval vibration turning head

A technology of elliptical vibration and turning tool post, which is applied in the direction of large fixed members, metal processing machinery parts, metal processing equipment, etc., can solve the problems of reducing device versatility, processing time and materials, and frequency dependence, so as to simplify control and reduce Motion-coupled, versatile effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

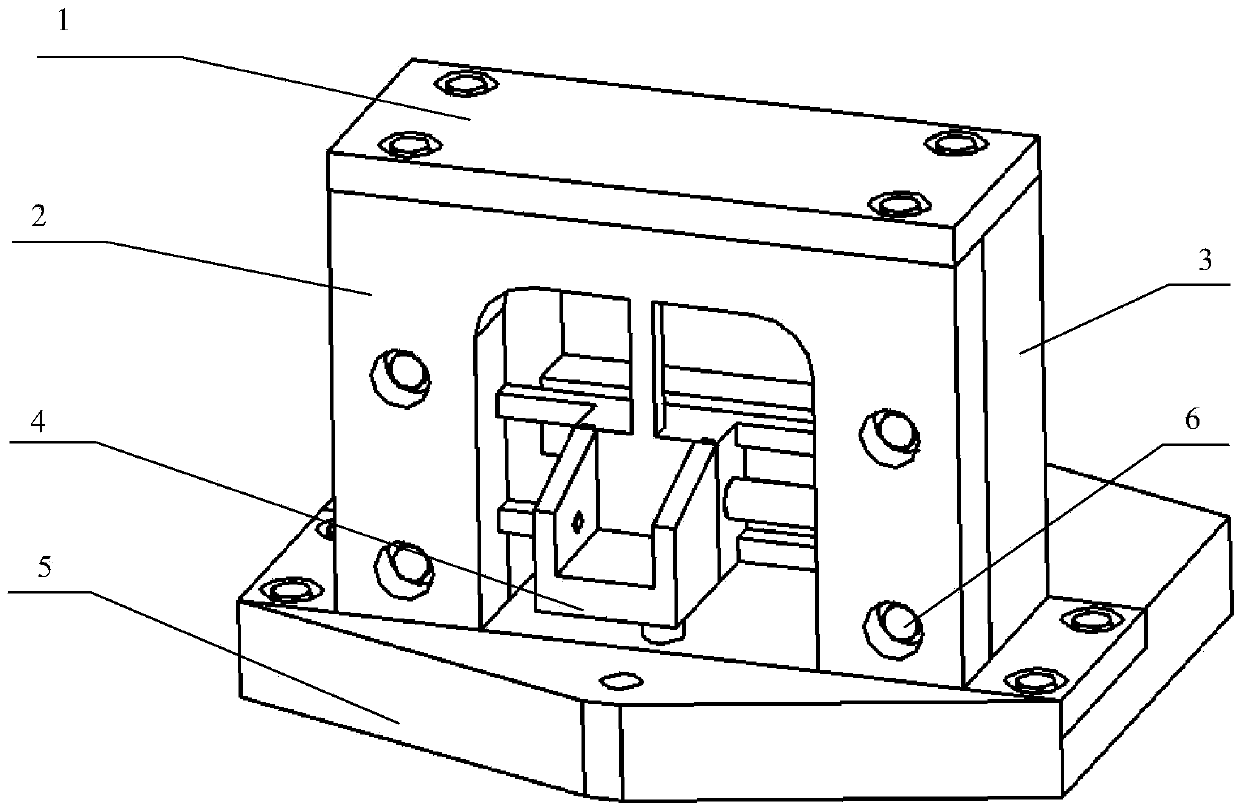

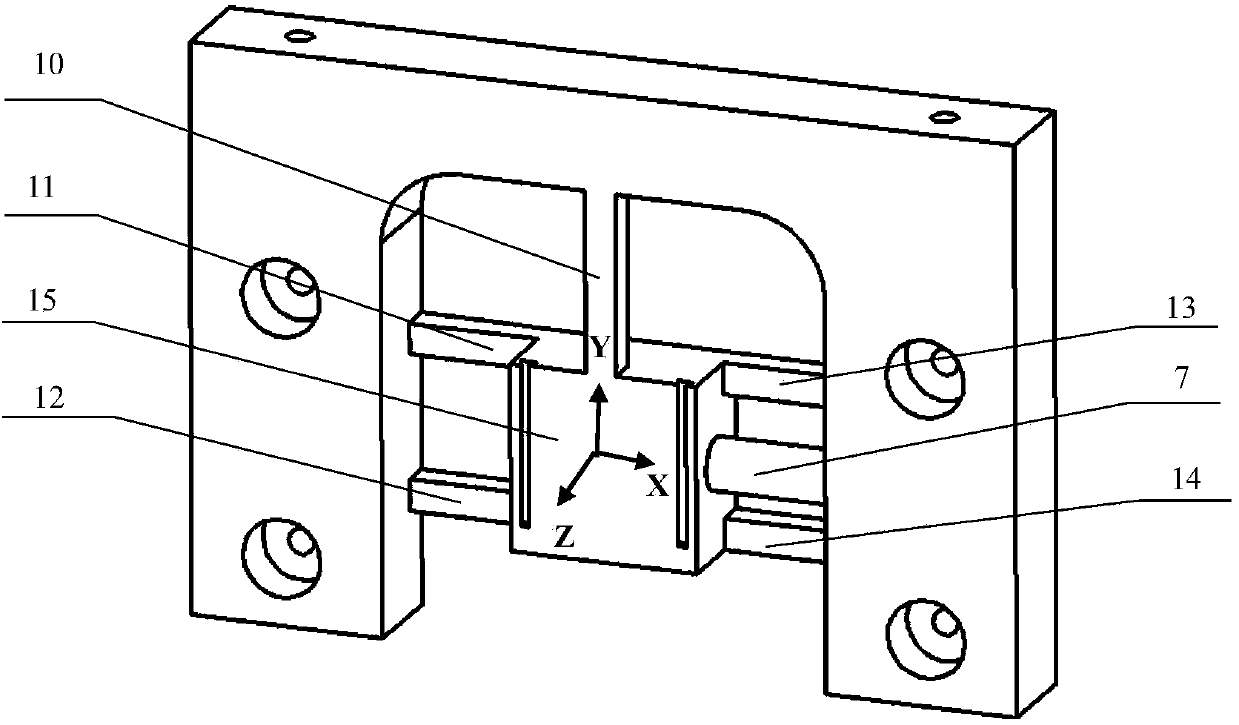

[0023] The present invention will be further described below in conjunction with the accompanying drawings. Such as figure 1 As shown, the micro-motion platform 15 is linked to the base 3 through the compliance unit A10, the compliance unit B11, the compliance unit C12, the compliance unit D13, and the compliance unit E14. The compliant unit B11, the compliant unit C12, the compliant unit D13, and the compliant unit E14 are arranged in parallel and distributed in the same plane with equal lengths. Compliant unit A10 is perpendicular to compliant unit B11 , compliant unit C12 , compliant unit D13 and compliant unit E14 , and is distributed in another plane. The two planes are parallel and have a certain distance. The micro-motion platform 15, five compliant units and the base 3 form the vibrating part 2 as a whole, and the vibrating part 2 belongs to a three-degree-of-freedom compliant mechanism;

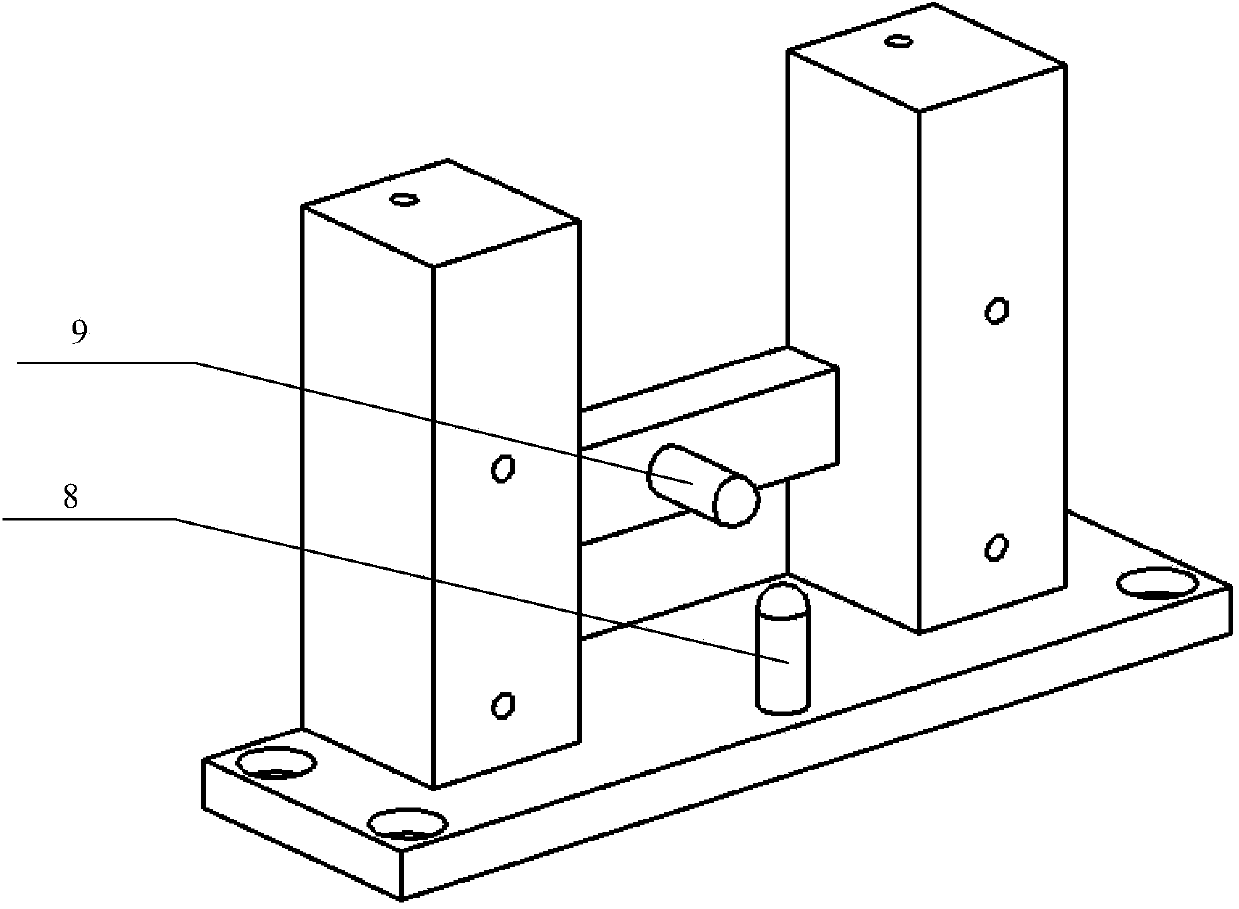

[0024] The fixture 4 is fixed to the micro-motion platform 15 through a T-sha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com