Large horizontal axial flow pump split guide vane casting method

A technology for axial flow pumps and guide vanes, which is applied in the casting field of split guide vanes for large horizontal axial flow pumps. It can solve the problems of unstable casting product quality, inability to cast oil pipe holes, and long construction period for manufacturing wooden molds, etc. problem, to achieve the effect of ingenious design, prevention of sand sticking on the surface, and short production cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

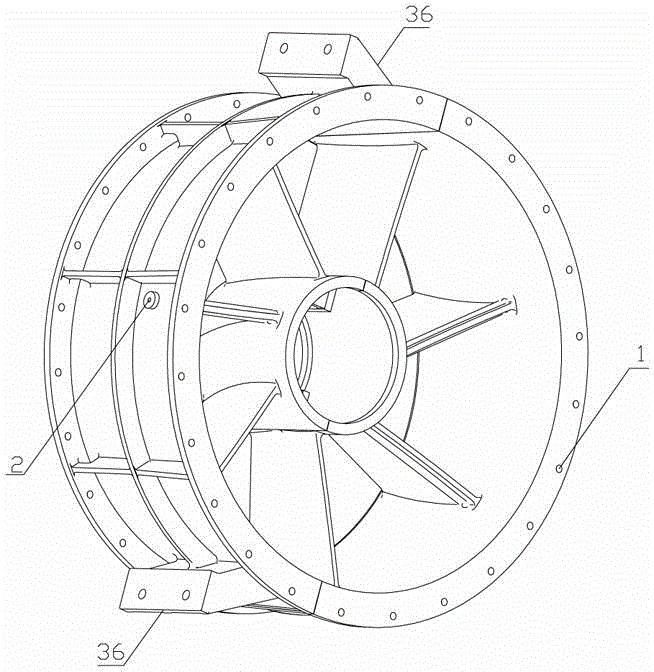

[0041] Cast as figure 1 The production method of the split guide vane body of the large horizontal axial flow pump shown includes the following steps:

[0042] (1) Use foam modules to make the upper half guide vane outer mold 34 (see Figure 16 , 17 ) And the lower half guide vane outer mold 35 (see Figure 18 , 19 );

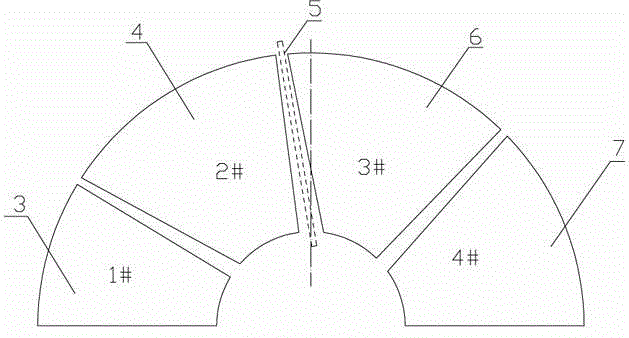

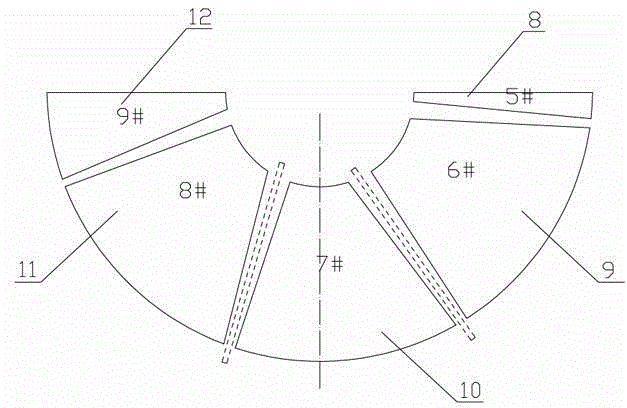

[0043] (2) Design the upper guide vane body sand model into four sand cores, such as figure 2 , Respectively are 1#sand core 3, 2#sand core 4, 3#sand core 6, 4#sand core 7, design the lower guide vane sand model into five sand cores, such image 3 , Respectively are 5# sand core 8, 6# sand core 9, 7# sand core 10, 8# sand core 11, 9# sand core 12; a special set of 1#-9# sand core general molding wood mold, the wood The mold has a sand core wooden box 13, see Figure 4 , The middle part is provided with a fan-shaped cavity 19 of 1 / 7 guide vane body. On both sides of the fan-shaped cavity on the top of the sand core wooden box 13, there are left and right mova...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com