Mercury-free catalyst for acetylene hydrochlorination

A non-mercury catalyst, acetylene hydrochlorination technology, applied in physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, organic chemistry, etc., can solve the problem of easy pulverization, high catalyst cost, and activated carbon strength It can improve the anti-wear strength, reduce the catalyst cost, and reduce the amount of gold.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

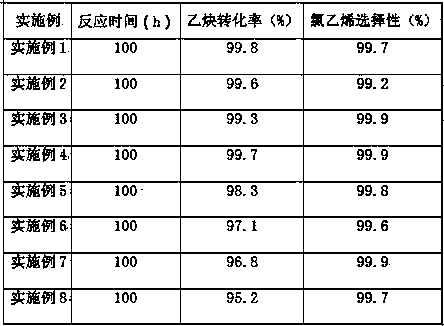

Examples

Embodiment 1

[0033] Weigh 1.9199g of SnCl 2 ·2H 2 O was dissolved in 40mL of absolute ethanol, and after mixing well, reflux and stir in a reflux stirring device at 78°C for 3h, and then stand and age in a 30°C constant temperature water bath for 8h to obtain a metal sol. The sol was sprayed onto 20g coconut shell activated carbon, and then dried at 80°C for 12 hours and 300°C for 4 hours to obtain coconut shell activated carbon with metal oxide film;

[0034] Weigh 0.4642g of Bi(NO 3 ) 3 ·5H 2 O and 2.2830g of Cu(NO 3 ) 2 ·3H 2 Dissolve O in 40mL of dilute nitric acid solution, then take 1.2mL of 16.7mg / mL HAuCl 4 ·4H 2 The aqueous solution of O was added to it, sprayed twice on the coconut shell activated carbon with oxide film, and then dried at 80°C for 12 hours and calcined at 200°C for 4 hours to obtain a non-mercury catalyst.

Embodiment 2

[0036] Weigh 1.9199g of SnCl 2 ·2H 2 O was dissolved in 40mL of absolute ethanol, and after mixing well, reflux and stir in a reflux stirring device at 78°C for 3h, and then stand and age in a 30°C constant temperature water bath for 8h to obtain a metal sol. The sol was sprayed on 20g coconut shell activated carbon, dried at 80°C for 12 hours, and baked at 300°C for 4 hours to obtain coconut shell activated carbon with metal oxide film;

[0037] Weigh 0.6200g Ce(NO 3 ) 3 ·6H 2 O and 2.2830g of Cu(NO 3 ) 2 ·3H 2 Dissolve O in 40mL of dilute nitric acid solution, then take 1.2mL of 16.7mg / mL HAuCl 4 ·4H 2 The aqueous solution of O was added to it, sprayed twice on the coconut shell activated carbon with oxide film, and then dried at 80°C for 12 hours and calcined at 200°C for 4 hours to obtain a non-mercury catalyst.

Embodiment 3

[0039] Weigh 3.8398g of SnCl 2 ·2H 2 O was dissolved in 40mL of absolute ethanol, and after mixing well, reflux and stir in a reflux stirring device at 78°C for 3h, and then stand and age in a 30°C constant temperature water bath for 8h to obtain a metal sol. The sol was sprayed onto 20g coconut shell activated carbon, and then dried at 80°C for 12 hours and 300°C for 4 hours to obtain coconut shell activated carbon with metal oxide film;

[0040] Weigh 0.4642g of Bi(NO 3 ) 3 ·5H 2 O and 2.2830g of Cu(NO 3 ) 2 ·3H 2 Dissolve O in 40mL of dilute nitric acid solution, then take 1.2mL of 16.7mg / mL HAuCl 4 ·4H 2 The aqueous solution of O was added to it, sprayed twice on the coconut shell activated carbon with oxide film, and then dried at 80°C for 12 hours and calcined at 200°C for 4 hours to obtain a non-mercury catalyst.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com