A pressure-increasing water jet vacuum cleaner

A water jet and vacuum cleaner technology, which is applied in the direction of vacuum cleaners, suction filters, cleaning equipment, etc., can solve the problems that the water jet pressure does not reach the preset target, the boosting effect is limited, and the running resistance is increased, so as to increase the friction factor and the effect Good, the effect of improving the dust collection ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

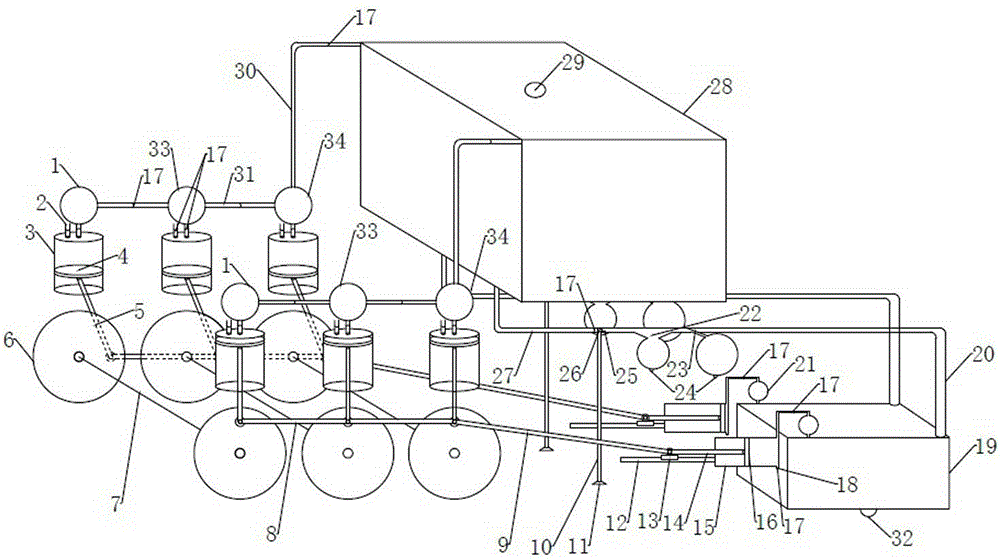

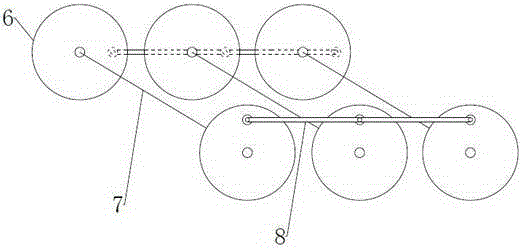

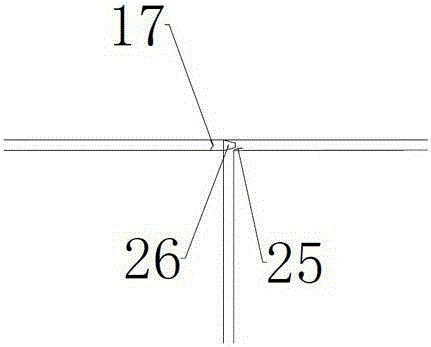

[0034] Such as figure 1 As shown, the pressure incremental water jet vacuum cleaner of the present invention includes a primary pressure storage chamber 1, an air suction hole 2, a booster chamber 3, a piston 4, a connecting rod 5, a driving wheel 6, a driving shaft 7, and a driving wheel connecting rod 8. Slider connecting rod 9, dust suction duct 10, dust suction port 11, sliding track 12, slider 13, negative pressure piston connecting rod 14, negative pressure generating chamber 15, negative pressure piston 16, one-way valve 17, exhaust Air hole 18, sewage collection chamber 19, sewage conveying pipe 20, anti-suckback chamber 21, vortex descaling chamber 22, garbage recovery chamber 24, nozzle 26, pressurized clean water conveying pipe 27, water tank 28, water injection port 29, high pressure Delivery pipe 30 , pressure delivery pipe 31 , garbage discharge port 32 , secondary pressure storage chamber 33 , and tertiary pressure storage chamber 34 .

[0035] Driving wheel 6 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com