Method for preparing ageratina adenophora extract by membrane separation

A technology of Eupatorium adenophorum extract, which is applied in the field of preparation of Eupatorium adenophorum extract by membrane separation, can solve the problems that hinder the popularization and application of Eupatorium adenophorum extract, reduce the content of active ingredients, destroy active ingredients, etc., and achieve active The effect of high ingredient content, short process and easy industrialization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

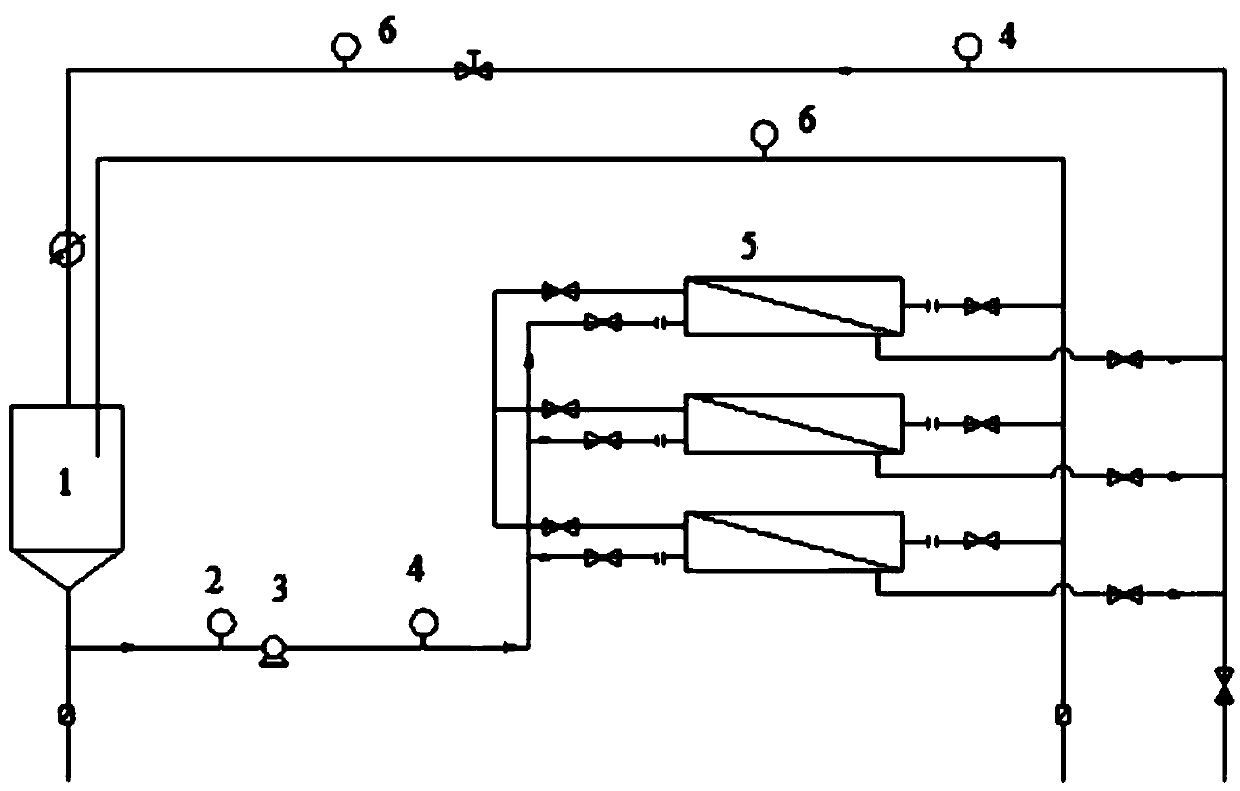

Method used

Image

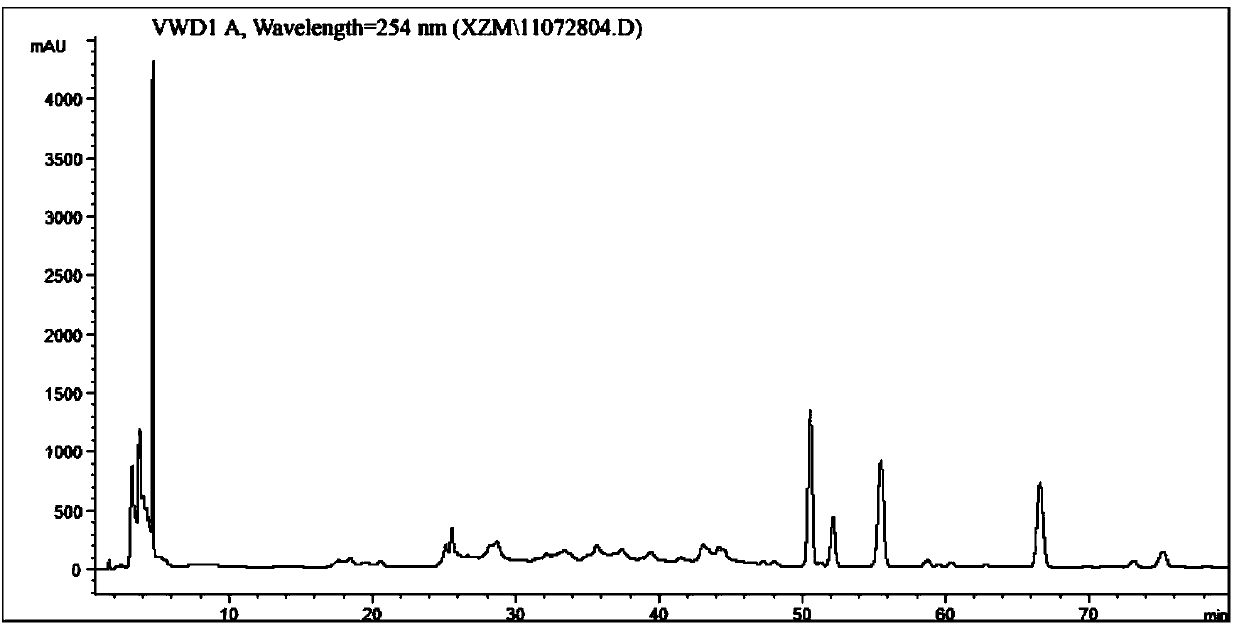

Examples

Embodiment 1

[0049] (1) The dried Eupatorium adenophorum leaves are pulverized and passed through a 40-mesh sieve to obtain Eupatorium adenophorum powder;

[0050] (2) put the Eupatorium adenophorum powder obtained in the 10kg step (1) into the extraction kettle, and add the ethanol that the mass fraction is 95%, soak under room temperature for 3 days, extract 3 times (the use quality of ethanol is respectively 50kg, 25kg, 25kg), 3 layers of gauze are filtered, and the filtrate is combined to obtain the extract of 86.7kg for subsequent use;

[0051] (3) Transfer the extract obtained in step (2) to the raw material tank, and use a microfiltration membrane (filter aperture is 0.13 μm, PS roll microfiltration membrane) to carry out microfiltration separation to remove larger solids and control the pressure 0.3~0.8MPa, as the microfiltration proceeds, the concentration of the material in the tank increases continuously, and new extract should be added at any time. When the extract obtained in ...

Embodiment 2

[0085] (1) The dried Eupatorium adenophorum leaves are pulverized and passed through a 60-mesh sieve to obtain Eupatorium adenophorum powder;

[0086] (2) put the Eupatorium adenophorum powder obtained in the 10kg step (1) into the extraction kettle, and add mass fraction as 60% ethanol, soak for 4 days under room temperature, extract 3 times (the use quality of ethanol is respectively 50kg, 25kg, 25kg), 3 layers of gauze are filtered, and the filtrate is combined to obtain the extract of 81.5kg for subsequent use;

[0087](3) Transfer the extract obtained in step (2) to the raw material tank, and use a microfiltration membrane (filter aperture is 0.13 μm, PS roll microfiltration membrane) to carry out microfiltration separation to remove larger solids and control the pressure 0.3~0.8MPa, as the microfiltration proceeds, the concentration of the material in the tank increases continuously, and new extract should be added at any time. When the extract obtained in step (2) is cl...

Embodiment 3

[0095] (1) The dried Eupatorium adenophorum leaves are pulverized and passed through a 60-mesh sieve to obtain Eupatorium adenophorum powder;

[0096] (2) Put 10kg of Eupatorium adenophorum powder obtained in step (1) into an extraction kettle, add acetone, soak for 1 day at room temperature, and extract 3 times (the use quality of ethanol is 50kg, 25kg, 25kg respectively) , filtered through 3 layers of gauze, and the filtrate was combined to obtain 89.5kg of extract for subsequent use;

[0097] (3) Transfer the extract obtained in step (2) to the raw material tank, and use a microfiltration membrane (filter aperture is 0.13 μm, PS roll microfiltration membrane) to carry out microfiltration separation to remove larger solids and control the pressure 0.3~0.8MPa, as the microfiltration proceeds, the concentration of the material in the tank increases continuously, and new extract should be added at any time. When the extract obtained in step (2) is close to the microfiltration s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Membrane pore size | aaaaa | aaaaa |

| Membrane pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com