Motor having one-body type stator core

A stator iron core, integrated technology, applied in the field of motors, can solve the problems of difficulty in the manufacturing process of the iron core for motors, unoptimized increase in the weight of automobiles, and difficulty in practical application, etc., to simplify the manufacturing process, reduce the loss of the iron core, reduce the The effect of manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] Hereinafter, embodiments of the present invention will be described in detail with reference to the drawings. In this process, the size or shape of the structural elements shown in the drawings will be enlarged to ensure clarity and convenience of description. In addition, terms specifically defined in consideration of the structure and operation of the present invention may vary depending on the user's or operator's intention or custom. These terms should be defined according to the entire content of this specification.

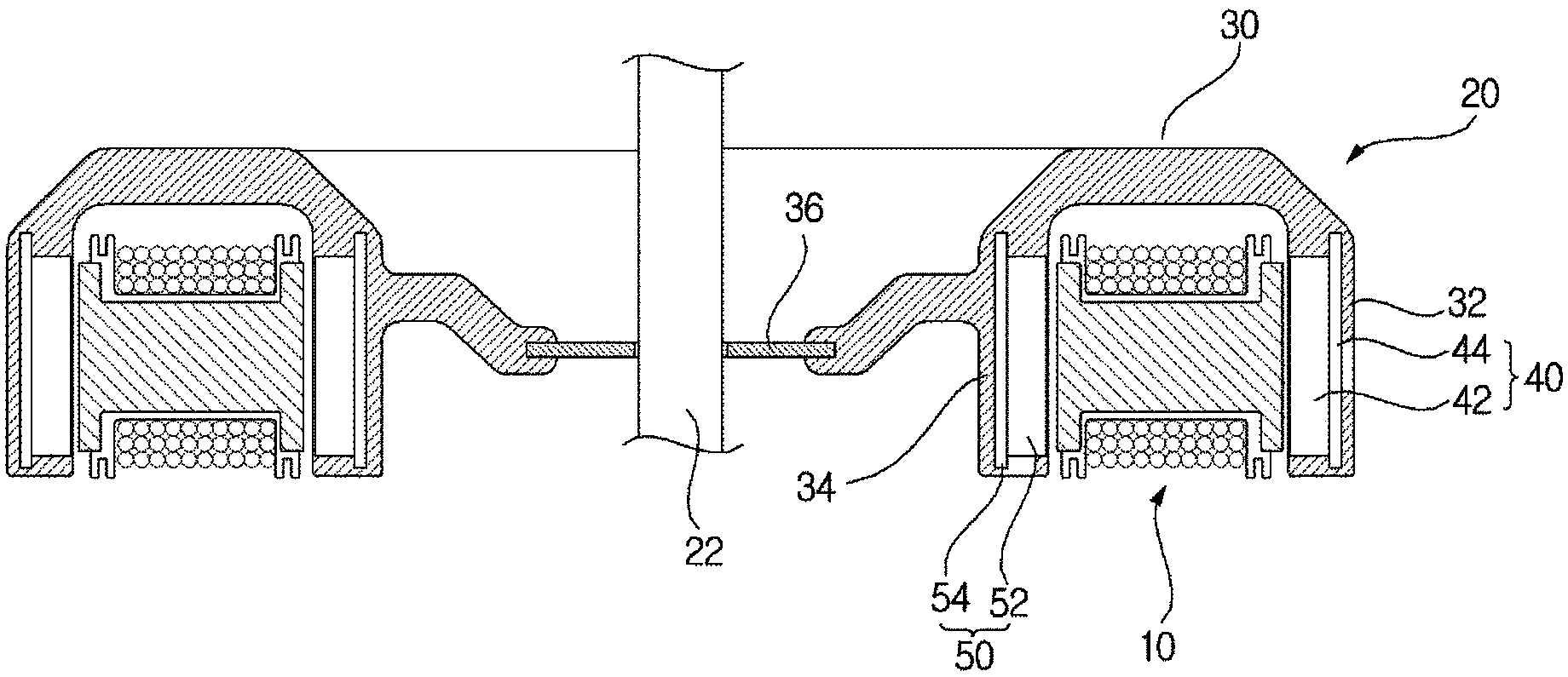

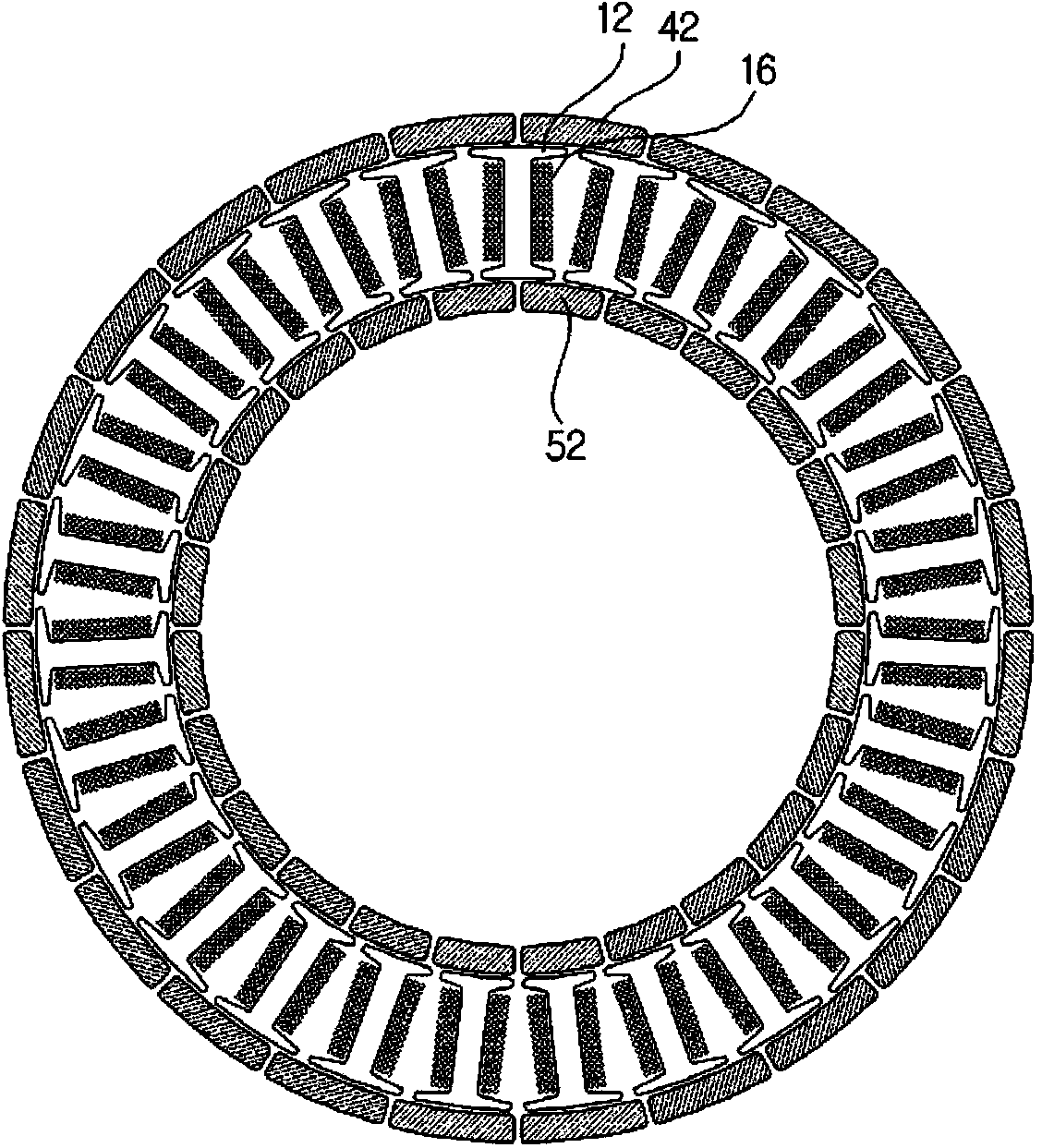

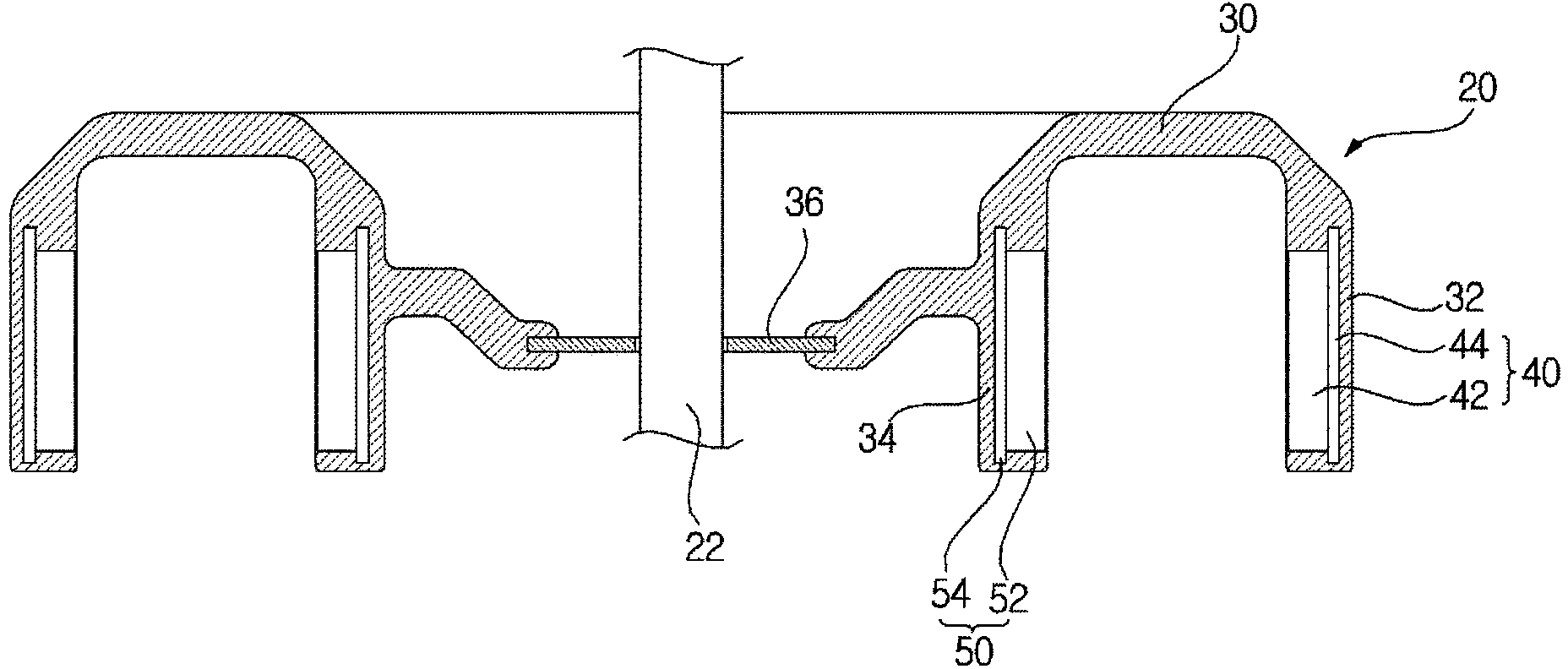

[0044] figure 1 is a sectional view of a motor according to an embodiment of the present invention, figure 2 It is a top view of a motor according to an embodiment of the present invention.

[0045] refer to figure 1 and figure 2 , The motor according to one embodiment includes: a stator 10 ; and a rotor 20 disposed on the outer peripheral surface and the inner peripheral surface of the stator 10 with a predetermined interval, and connected to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com