Piston pump for a high-pressure cleaning device

A high-pressure cleaning, piston pump technology, applied to components of pumping devices for elastic fluids, cleaning methods using liquids, mechanical equipment, etc., can solve the problem of limiting casing productivity, increasing piston pump manufacturing costs, and long cooling processes. And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

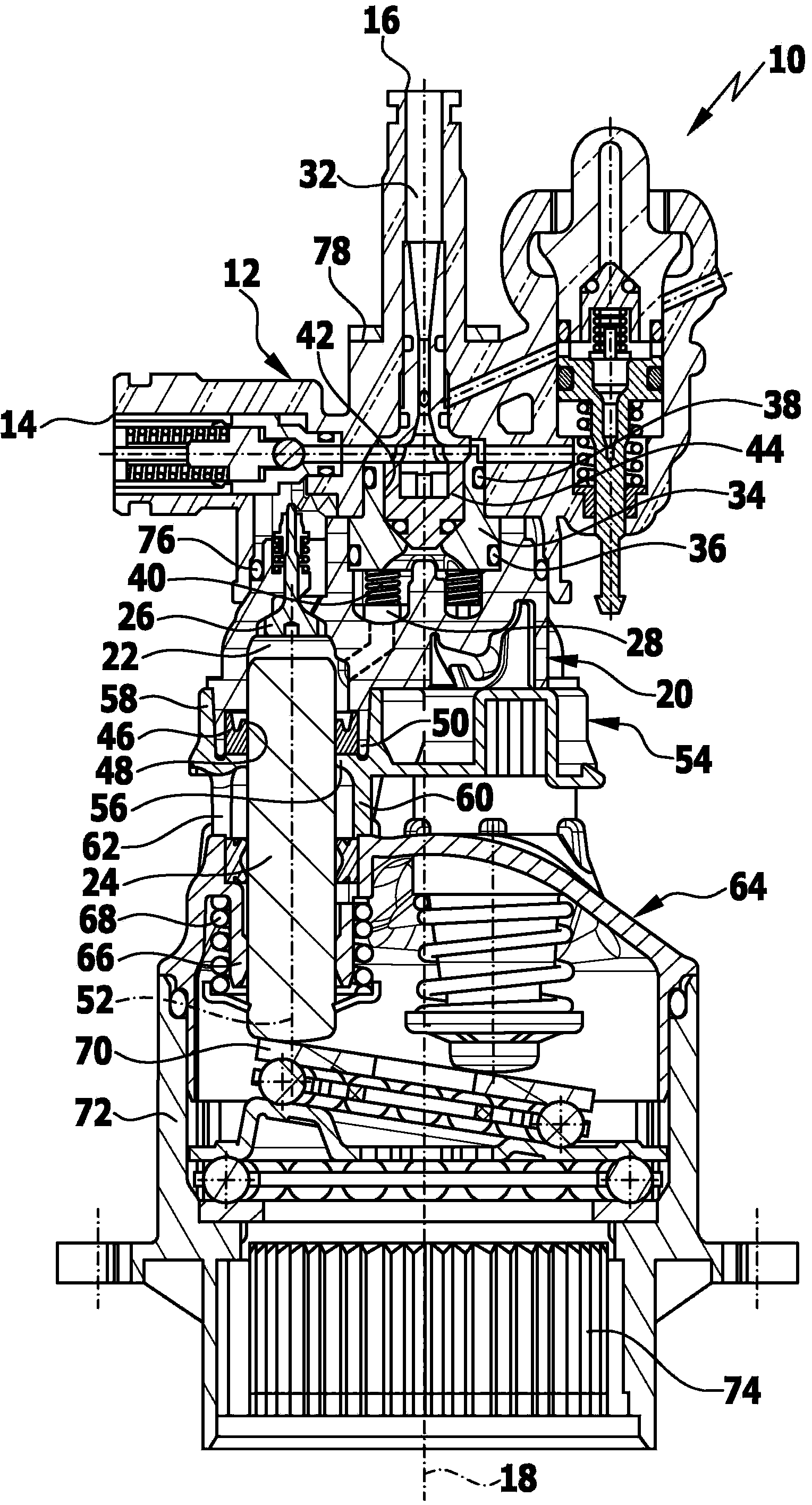

[0026] An advantageous embodiment of the piston pump according to the invention, which is designated as a whole by the reference numeral 10 , is shown schematically in the drawing. The piston pump 10 comprises a pump head 12 with a suction inlet 14 via which a fluid to be pressurized, preferably water, can be delivered to the piston pump 10 . For example, a supply line can be connected to the suction inlet 14 . Furthermore, the pump head 12 has a pressure outlet 16 via which pressurized liquid can be discharged. For example, a pressure hose can be connected to the pressure outlet 16 , which pressure hose carries at its free end a discharge device for the pressurized liquid, for example a spray gun or a nozzle.

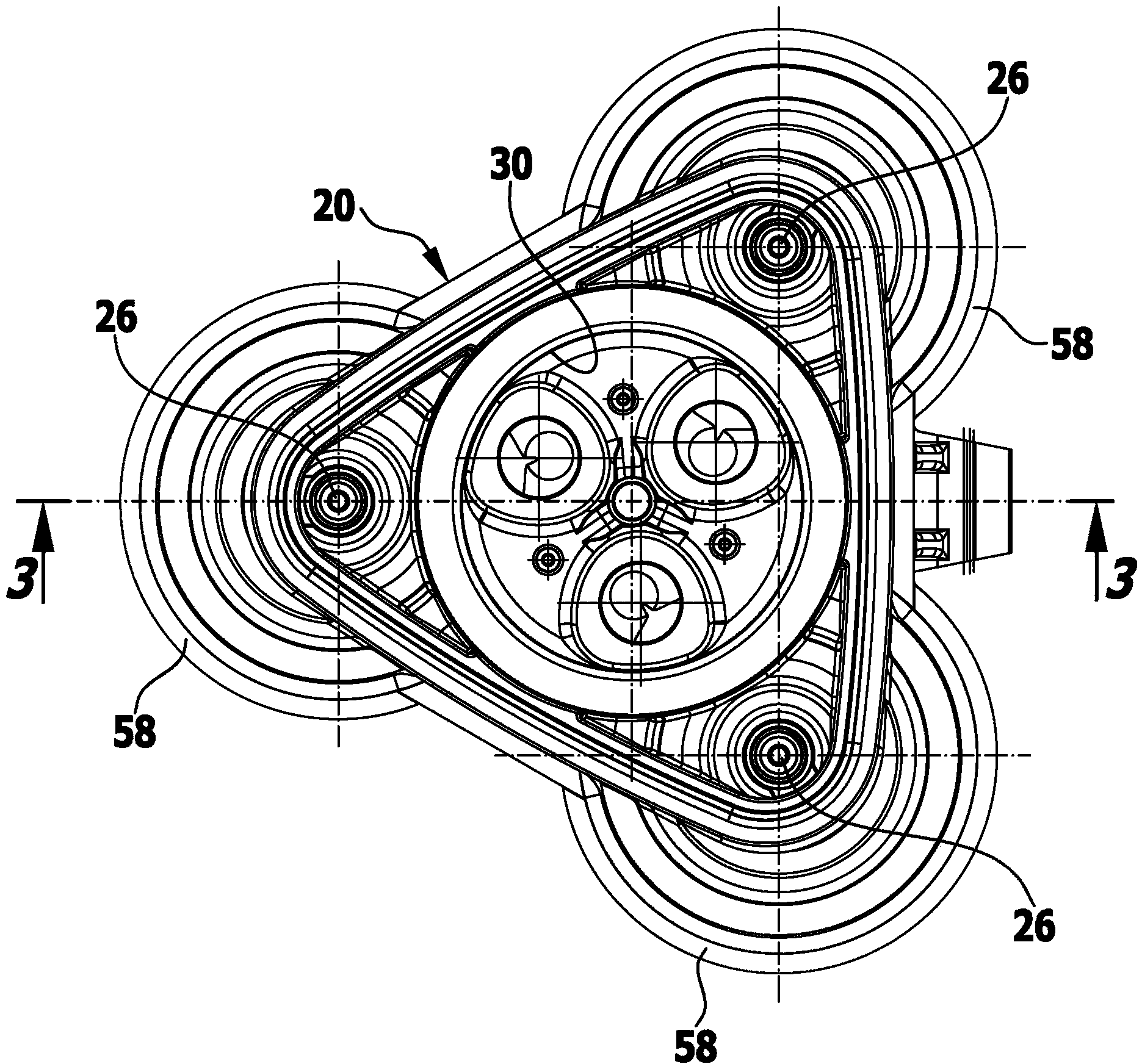

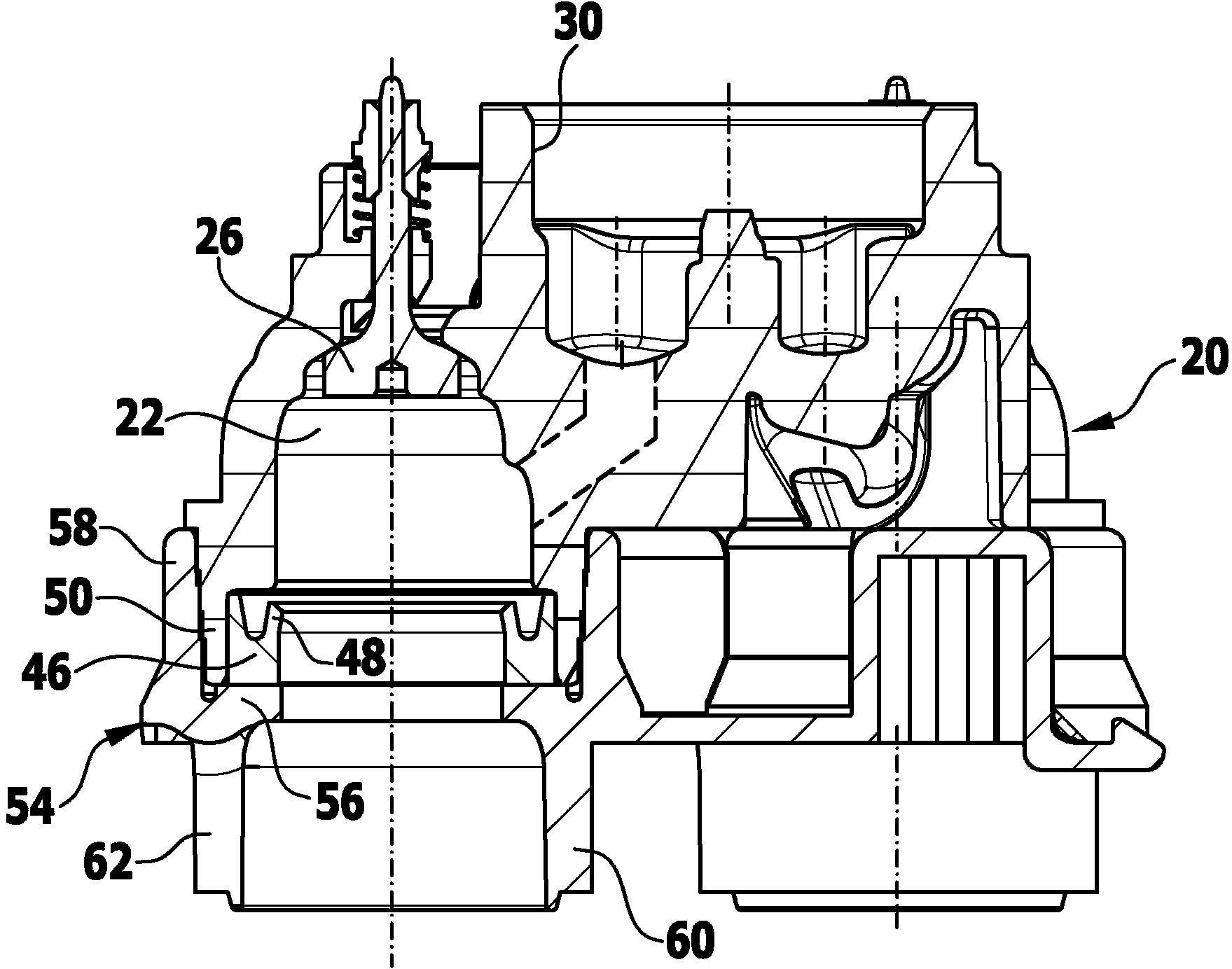

[0027] The pump head 12 is arranged in an axial direction based on the pump longitudinal axis 18 on a pump body 20 which has a plurality of pump chambers 22 into which pistons 24 each protrude. The piston pump 10 illustrated in the drawing has overall three pump cham...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com