Thermoplastic resin composition, method for producing same, and molded article

A thermoplastic resin, thermoplastic elastomer technology, applied in the field of thermoplastic resin composition and its manufacture, thermoplastic resin composition and molded body, to achieve the effects of reduced content, excellent rigidity and excellent impact resistance properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

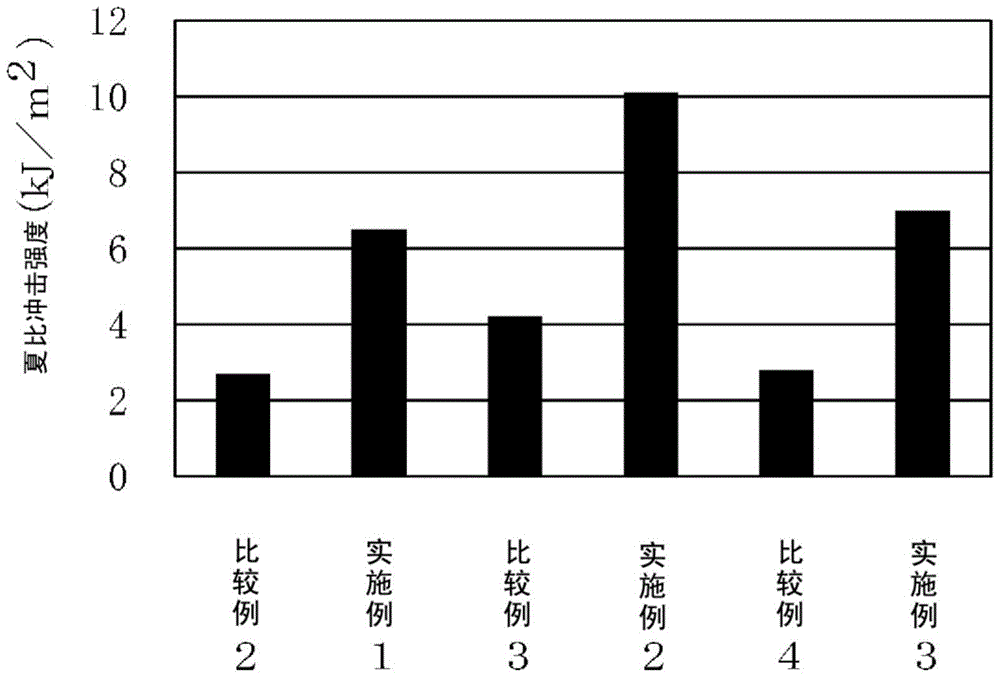

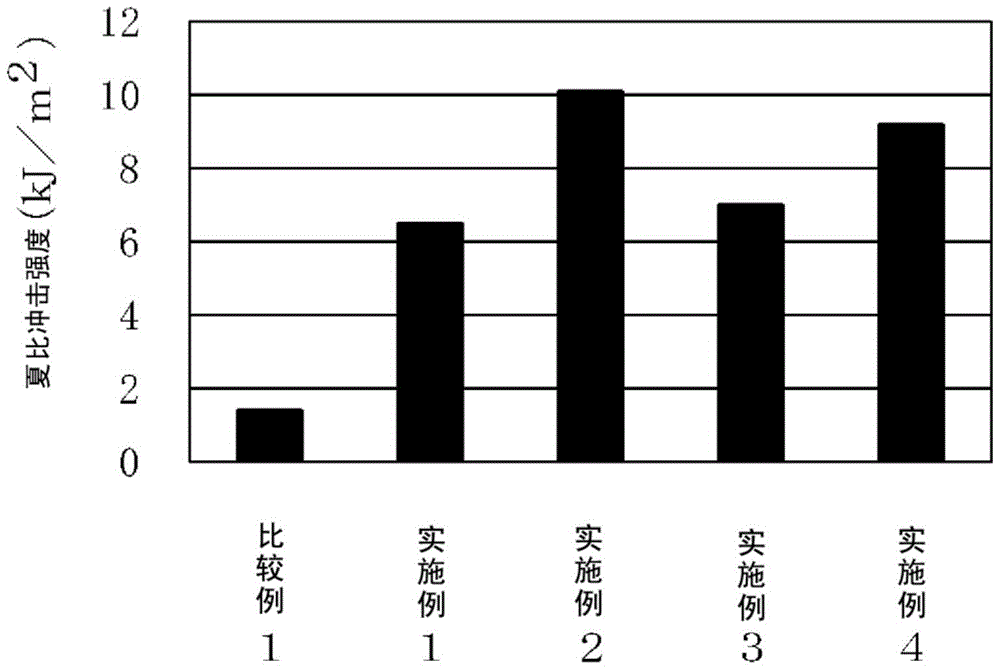

[0201] Hereinafter, the present invention will be described more specifically by way of examples.

[0202] [1-1] Production of thermoplastic resin composition (I) using PA11 as polyamide resin and production of test piece

[0203]

[0204] (1) Preparation of mixed resin

[0205] (A) PA11 (nylon 11 resin, manufactured by Arkema K.K., trade name "Rilsan BMNO", weight average molecular weight 18,000, melting point 190°C) was used as polyamide resin, and maleic anhydride-modified EPR was used as compatibilizer (C) (manufactured by Mitsui Chemicals, Inc., trade name "TAFMER MP0620", MFR (230° C.) = 0.3 g / 10 minutes), these pellets were dry-blended according to the proportion shown in Table 1, and then put into twin-screw melt kneading Extruder (manufactured by TECHNOVEL Corporation., screw diameter 15mm, L / D=59), mixed under the conditions of 210° C. of kneading temperature, 2.0 kg / hour of extrusion speed, and 200 revolutions / minute of screw speed, and then used The pelletizer ...

Embodiment 2

[0210] (C) Maleic anhydride-modified EBR (manufactured by Mitsui Chemicals, Inc., trade name "TAFMER MH7020", MFR (230° C.) = 1.5 g / 10 minutes) was used as a compatibilizer, and the formulation shown in Table 1 was used. Pellets of the thermoplastic resin composition of Example 2 were produced in the same manner as in Example 1 except that the respective pellets were dry-blended. Next, injection molding was performed in the same manner as in Example 1 to obtain a test piece for measuring physical properties of Example 2.

Embodiment 3

[0212] (C) Maleic anhydride-modified SEBS (manufactured by Asahi Kasei Chemicals Corporation., trade name "Tuftec M1913", MFR (230° C.) = 5.0 g / 10 minutes) was used as a compatibilizer, and the compounding ratio shown in Table 1 was used. Pellets of the thermoplastic resin composition of Example 3 were produced in the same manner as in Example 1 except that each pellet was dry-blended. Next, injection molding was performed in the same manner as in Example 1 to obtain a test piece for measuring physical properties of Example 3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| Charpy impact strength | aaaaa | aaaaa |

| Charpy impact strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com